Reasons Why You Should Use Fiberglass Rebars in Your Project

In the world of construction and infrastructure, the materials we choose play a significant role in the integrity, longevity, and safety of structures. While steel has long been a popular choice for reinforcing concrete, the industry is evolving, and a growing number of professionals are turning to an alternative solution: fiberglass rebars. In this in-depth exploration, we’ll delve into the reasons behind this shift and why you might want to consider using GFRP rebars in your next project.

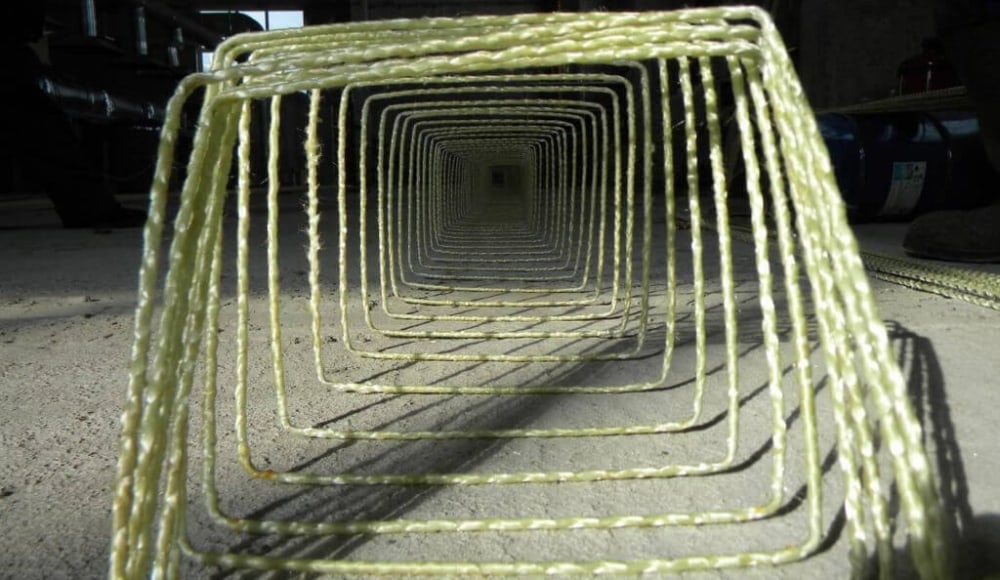

1. Understanding Fiberglass Rebar

Before diving into the advantages, it’s essential to understand what exactly we’re talking about. Fiberglass rebar, often referred to as FRP (Fiber Reinforced Polymer) rebars or GFRP (Glass Fiber Reinforced Plastics) rebars, is a composite material. This means it’s made of two or more substances that, when combined, produce a product with properties distinct from the original materials. FRP materials, in this case, involve fibers (like glass) and a polymer matrix.

2. Durability and Longevity

One of the primary reasons many choose fiberglass rebar over steel is its resistance to corrosion. Unlike steel, which can corrode when exposed to air and moisture over time, GFRP rebars don’t. This inherent resistance ensures that structures remain sturdy and sound for a more extended period, reducing the need for frequent maintenance or replacements.

3. GFRP Rebar vs. Steel: A Weighty Difference

Fiberglass rebars are notably lighter than their steel counterparts. This lighter weight makes transport, handling, and installation much more efficient. Teams can move more rebars with less effort, translating to reduced labor costs and faster project completion.

4. Electromagnetic Neutrality

In our tech-savvy world, the fact that fiberglass rebar is electromagnetically neutral can be a significant advantage. Unlike steel, which can interfere with magnetic fields, FRP products, including rebars, do not conduct electricity. This makes them ideal for structures that house sensitive electronic equipment or are located near high-voltage areas.

5. Cost-Effectiveness: Fiberglass Rebar Cost

While the initial price of fiberglass rebar might be higher than steel on a per-unit basis, considering the long-term savings paints a different picture. With the reduced need for maintenance, replacements, and the efficiency in transportation and installation, the overall fiberglass rebar cost often turns out to be more economical in the long run.

6. Diverse Range of GFRP Products

The fiberglass rebar industry doesn’t stop at rebars. There are various FRP products available, such as frp mesh , which can be used as a reinforcing agent in concrete. Then there’s the frp bent elements, which are uniquely shaped rebars tailored for specific structural needs. This diversity ensures that whatever your project requirements, there’s likely an FRP solution available.

7. Flexibility and Tensile Strength

FRP rebars have a higher tensile strength compared to steel. This means they can bear more load without breaking, making them suitable for areas prone to natural disasters like earthquakes. Their flexibility also allows for some movement without compromising the structural integrity.

8. Thermal Insulation

One often overlooked advantage of GFRP rebars is their thermal insulating properties. Unlike steel, which can rapidly conduct heat, fiberglass rebars can help maintain a more consistent temperature within a structure. This can be particularly beneficial in climates with extreme temperature fluctuations.

9. Eco-friendly Production

The production process for fiberglass rebars is generally more environmentally friendly than that of steel. With an increasing push towards green and sustainable construction practices, opting for FRP materials can be a step in the right direction.

10. Advanced FRP Rebar Equipment

As the demand for fiberglass rebars grows, so does the technology and equipment used in their production and installation. Modern FRP rebar equipment ensures that these rebars are made with precision and meet the highest industry standards. This equipment also makes it easier for construction teams to work with the material on-site.

Conclusion

The decision to shift from traditional materials like steel to newer, innovative solutions like fiberglass rebars isn’t one to be taken lightly. But as we’ve explored, there are numerous compelling reasons to consider making the switch. Whether you’re driven by the long-term cost savings, the composite rebar advantages, or the eco-friendly production processes, it’s clear that fiberglass rebars hold significant potential for the future of construction.

Incorporating keywords like “fiberglass rebar,” “FRP rebars,” and “ fiberglass rebar vs. steel ” naturally into our discourse emphasizes the growing importance of these materials in modern construction. As the industry continues to evolve, it’s essential to stay informed and consider the vast benefits of integrating FRP products into your projects.