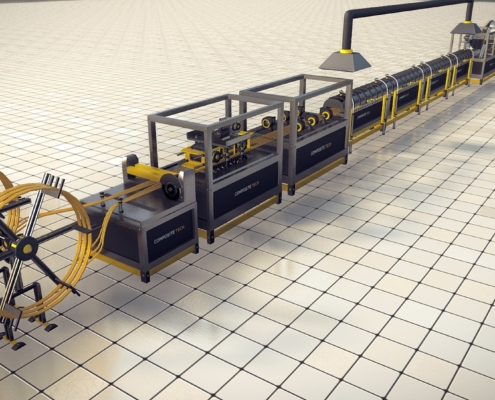

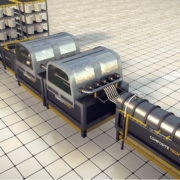

High-quality GFRP rebar production line

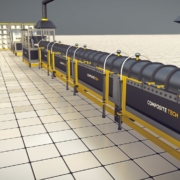

Our FRP Rebar production line has been perfected over the course of the last 10 years and has now reached its peak product stage. Resultantly, we have achieved non-stop production process flow and made sure that it requires zero to none upkeep input, whilst producing a constantly high quality of end product at maximum output.

We manufacture 2 different GFRP production lines:

- CT4 has simultaneous output of 4 bars

- CT6 has simultaneous output of 6 bars

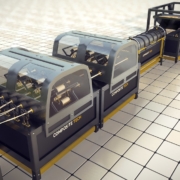

Our equipment is designed to be reliable, highly productive and unique in the technology we utilise! All our developments and innovations are patented, which guarantees not only high effectiveness of your investment, but also a competition free market. Moreover, to ensure reliability of all production line modules we use only those components that have passed our rigorous tests and performance evaluations.

By acquiring Composite Tech FRP rebar production equipment, our clients also have following deliverables:

– Assistance in the selection of special premises

– Our specialists carry out installation of equipment and perform commissioning works

– Staff training

– Ongoing advice to your technical experts

Technical characteristics

Technical characteristics of the line for the production of composite reinforcement:

| Purpose: | manufacture of fiberglass or basalt fiber reinforcement |

| Diameter of products: | from 2 mm to 30 mm. |

| Voltage: | 380 V / 50 HZ |

| Power: | 26 kw |

| Line Performance: | 6-26 running meters per minute |

| Equipment Length: | 45m |

| Width: | 1.2m |

| Height: | 1.6m |

Depending on the configuration our production lines can be used to simultaneously produce either 4 (CT4) or 6 bars (CT6), significantly increasing productivity.

GFRP rebar produced by our equipment has enhanced strength properties (rupture strength, breaking strength and tensile strength), which is appreciated by professional construction companies across the globe.

We have achieved such performance as a result of a very large amount of work done in collaboration with various universities and research centres that specialise in composite materials and advanced construction industry technologies.

Turn-key GFRP Rebar Production!

Own an FRP/Basalt Rebar production line that unlike steel is not subjected raw materials cost fluctuations.

Application areas:

- Reinforcement of stone and armocamage structures.

- Reinforcement of the facade layer of three-layer protective structures.

- Reinforcement of concrete plates.

- Reinforcement of the floor tile in residential premises.

- Reinforcing horizontal layer seams.

Civil engineering

Industrial engineering

- Strengthening the road cloth with a composite grid

- Reinforcement of industrial floors.

- Reinforcement chemical waste storage

- Reinforcement of treatment faciliti

- Reinforcing settings for waste treatment.

- Reinforcement of storage of agricultural waste

- Reinforcement of agricultural waste storage.

- Reinforcement of floors in animal breeding complexes, farmes.

Agriculture

Road construction

- Application of a composite grid as a clothing for roads.

- Reinforcement of road plates.

- Strengthening of the road.

- Reinforcement of plates of the bridge mester

- Reinforcement of walkways

- Strengthening and construction of shore and hydrotechnical structures.

Construction of bridges and hydraulic structures