Fiberglass reinforcing mesh is designed for concrete reinforcement as well as road and highway overlays. It prolongs the pavement lifespan by reducing the effects of reflective cracking caused by traffic loads, age hardening and temperature cycling. This aids the pavement life span between service maintenance significantly. Fiberglass reinforcing mesh makes it possible to reduce thickness of asphalt concrete pavement of up to 20%, and is also applicable in strengthening of structures’ foundations.

Content

The benefits of the GFRP Mesh are as follows

- Corrosion resistant – GFRP rebar, GFRP mesh, GFRP bent elements do not rust and are immune to salt ions, chemicals and concrete inherent alcalines. This is important when you build concrete structures in coastal areas near seas, oceans, lakes and rivers. FRP is not affected by corrosion and this means that concrete won’t crack as rebar will not expand like steel.

- Zero decay – GFRP rebar eliminates cracks in the concrete blocks and consequent breaking of structure. Therefore, we extend life expectancy of the blocks and eliminate the need for refurbishment. Our tests show that concrete structures will remain intact for over 80 years without critical cracks and deformation of the structures that contain GFRP rebar

Price – Steel has doubled in price since mid 2020, whilst the general market suffers from constant fluctuations. This makes it hard to forecast your steel rebar production prices. Opposingly, FRP Rebar raw materials have historically been decreasing in price and maintain a stable price behaviour. - Strength and temperature resistance – GFRP Mesh is at least 5 times stronger than steel. The end product of our production lines withstands -70 to +150 degrees Celsius range of temperatures and is 5 times stronger than its steel counterpart.

- Transportation – GFRP rebar is over 5 times lighter than steel. This multiplication factor means that you can transport at least 5 times more FRP rebar using the same machinery and transportation techniques as with steel rebar. This then becomes an integral part of your cost and profitability calculations, decreasing these factors to minimum.

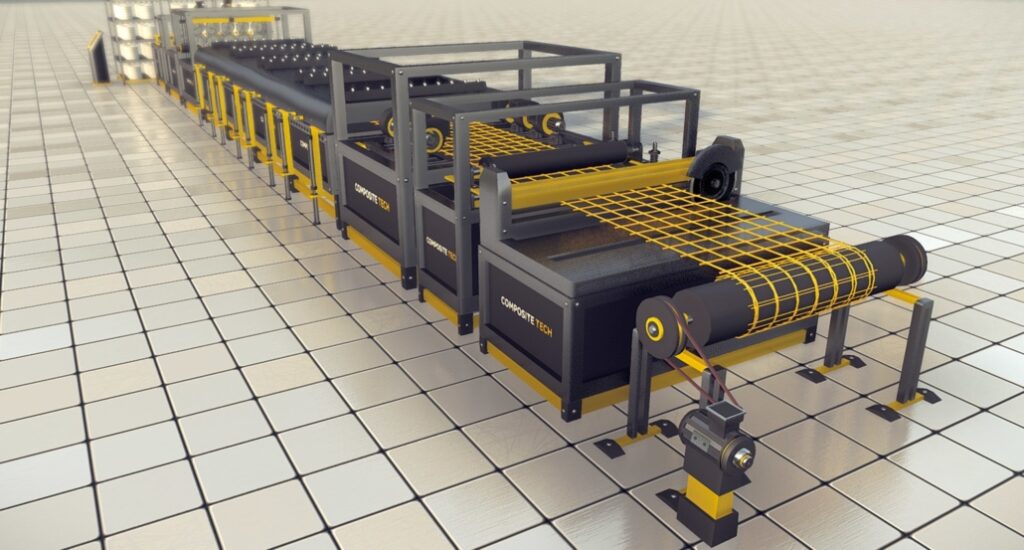

Application of Composite-Tech GFRP Mesh

- All types of foundations

- Construction in sea water or in close proximity to it

- Concrete exposed to deicing salts (Roads, tunnels, bridges, etc)

- Weight sensitive structures

- Heat/cold sensitive environments (basements, patio decks, heated floors, etc)

- Low electric conductivity mediums (hospitals, airports, telecom structures, factories, manholes, etc)