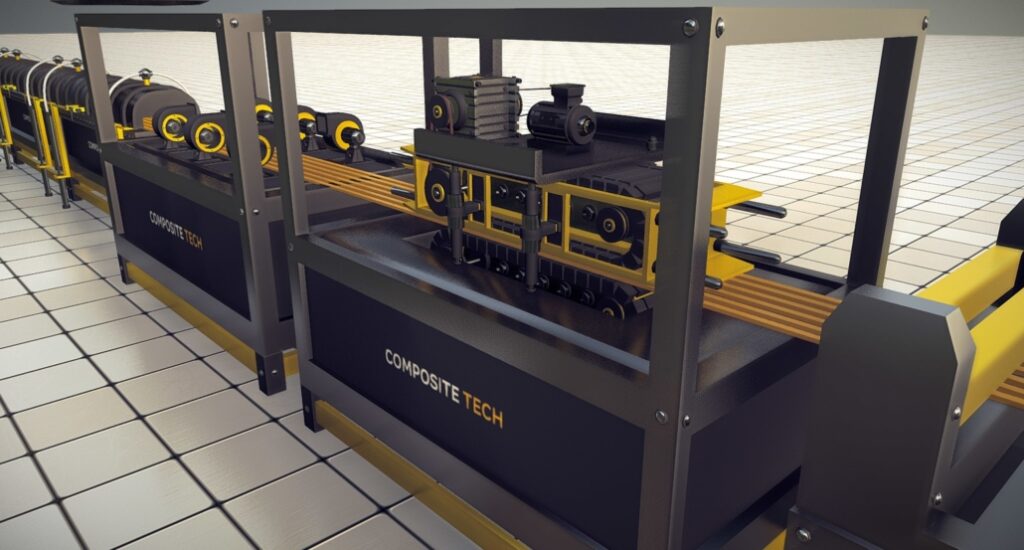

FRP mesh and FRP rebar production lines from Composite-Tech are recognized globally due to their unchallengeable quality. The enhanced properties of materials used during the manufacturing process ensure increased strength and high performance of production lines.

Content

Production Line Service Package

Besides offering top-grade production lines, the company provides:

- Diversified assistance in the selection and evaluation of premises suitable for production lines’ installation

- Full-service installation, check-out, and start-up works are performed by the company’s qualified team.

- In-situ training and continuous support for the staff and technical personnel

Requirements for Production Facilities

Composite-Tech’s experts provide close consultation on compliance of industrial premises with composite reinforcement production lines’ installation requirements.

General requirements:

- Building spaces: at least 40 m in length and at least 3m in height.

- Air temperature: 15 °С and higher (recommended 20 °С -25 °С).

- Ventilation: during the manufacturing process that involves operations with polymers, such as basalt fibre and fibreglass, and cutting composite reinforcement products, dust and gases are formed; hence, to ensure the safety of the personnel production facility should have a ventilation system to guarantee air exchange and withdrawal of fumes and dust.

Materials Used for Manufacturing Composite Reinforcement and Reinforcing Mesh

All materials and components used in manufacturing production lines are thoroughly selected and tested to ensure the durability, safety, and reliability of our final products. The company operates in close cooperation with reputable specialised research centres to continuously improve the properties of fibreglass and composite materials.

Production of FRP rebars and composite mesh is based on using:

- FRP (also known as fibre-reinforced plastic) and basalt fibre.

- Binding components (resins).

Polymers, fibreglass and basalt fibre carry on mechanical loading, while resins ensure reinforcement and protect from the environmental impact. The company pays close attention to the choice of raw materials and suppliers. Besides, multiple rupture, breaking, and tensile tests are performed to guarantee endurance and wear resistance.

FRP Mesh and FRP Rebar Production Lines: Experience, Credibility, and Quality

With over 10 years of experience in the market, Composite-Tech has developed and fine-tuned the manufacturing process to ensure top-notch quality.

Customers from all over the globe choose FRP mesh and FRP rebar production lines manufactured by Composite-Tech because we offer:

- Industrial-grade composite reinforcement production line design. Experts in engineering and construction have developed an efficient in-house production process with no intermediaries or contractors.

- Customer service. Technical specialists provide ongoing support to all company’s clients, from pre-sale preparation, installation, adjustment and alignment to post-sale service.

- Reasonable pricing. The durability of our production lines is based on a thorough selection of materials, professional design, and testing. All costs are justified in a short time due to efficient performance and high output.

- In-house software development and IT support.

What Is Included in the Price?

FRP rebar production lines are capable of producing 4 bars simultaneously.

Composite-Tech offers two variants of FRP mesh production lines: 1-metre wide mesh and 2-metre wide mesh.

When you purchase an FRP mesh or FRP rebar production line, you also receive:

- Production line installation, launch, and maintenance services.

- The list of recommended suppliers.

- Assistance in getting required certificates (full documentation on compliance with the quality standard)

- Software installation and regular updates.

- The detailed guide on the production technology, including production process standards and regulations, quality manuals, and a detailed technical description.

- Warranty and backup service.

The company has a solid reputation as a trustworthy manufacturer of composite reinforcement and reinforcing mesh production lines. Advanced technologies implemented throughout the manufacturing process, state-of-the-art equipment, and test-driven material selection received wide and confident acceptance among the leading construction companies.

Learn more: Why Producing GFRP Rebar is Profitable? Complete Cost Calculation