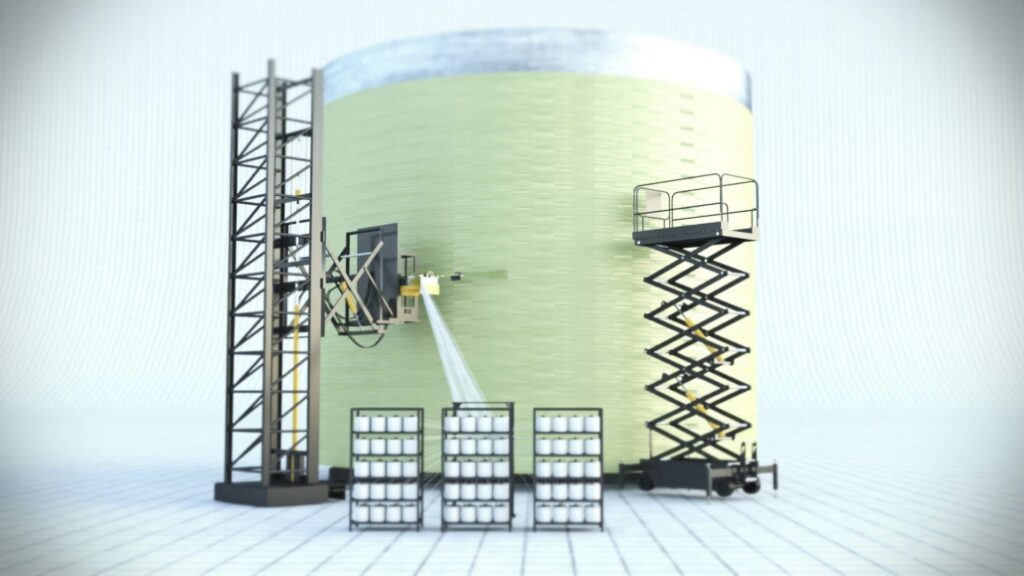

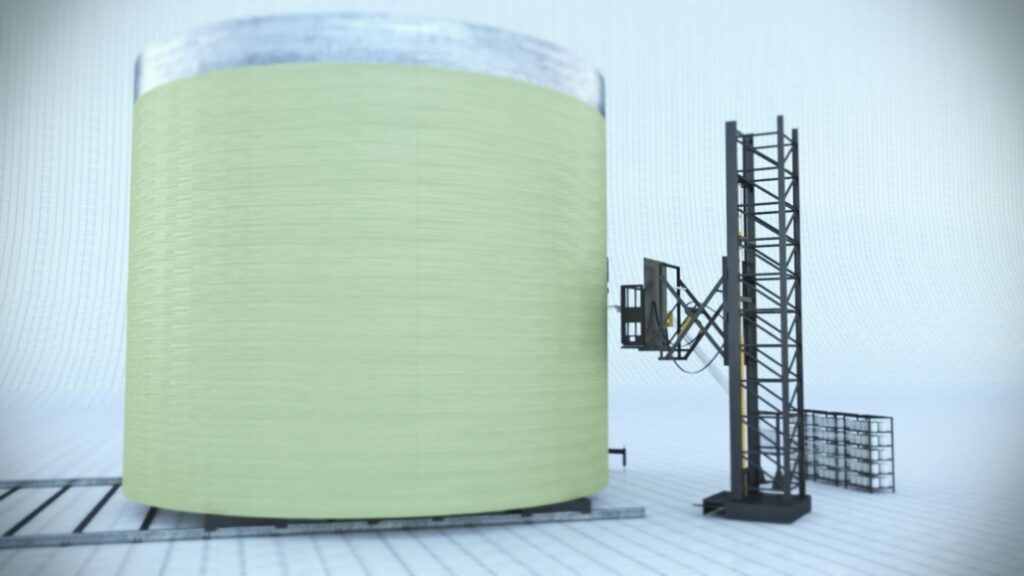

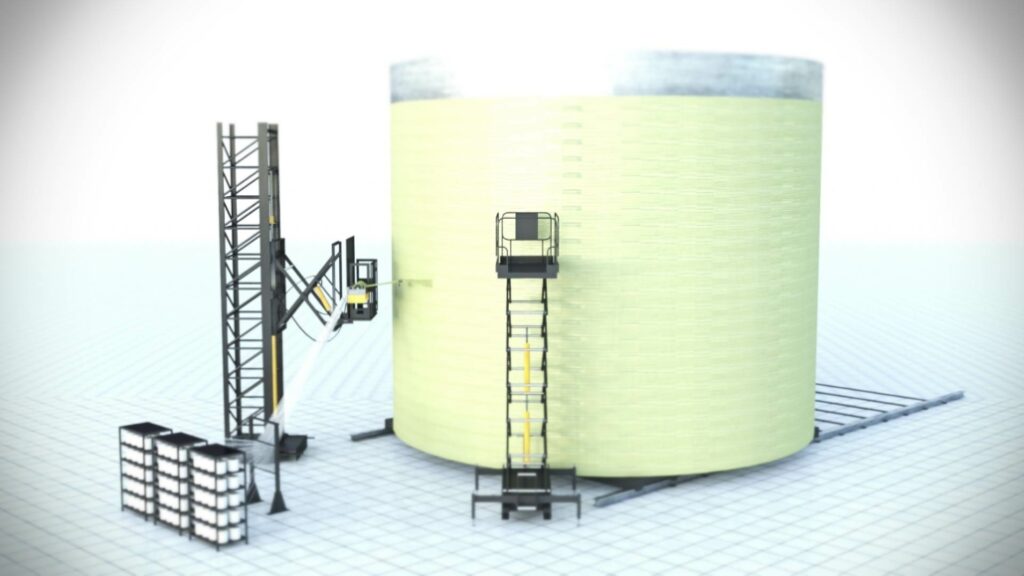

Composite-Tech takes the composites industry further than ever before by introducing our newly developed FRP silo production line. The composite silos made out of fiberglass boast a plethora of advantages over conventional metal heavy duty silos, elevating the industry to a new level of sustainability and effectiveness.

Composite-Tech FRP silo production lines offer:

- Full automation

- Wide range of silo types and application (see below)

- Cost effective production technology

- Sustainable production process

Composite-Tech GFRP composite silo types are used in:

- Oil & Gas industry

- Agriculture industry (grain storage and more)

- Water storage

- Waste and sea water

- Chemicals storage

- Low oxygen / High pressure

Possible FRP silo shapes made possible with our production line:

- Standard silo

- Flat bottom

- Hopper (funnel bottom silo)

- Truck/train loading

- Variable dimension

Our equipment is designed to be reliable, highly productive and unique in the technology we utilise! All our developments and innovations are patented, which guarantees not only high effectiveness of your investment, but also a competition free market. Moreover, to ensure reliability of all production line modules we use only those components that have passed our rigorous tests and performance evaluations.

By acquiring Composite-Tech GFRP silo production equipment, our clients also have following deliverables:

- Calculations tied to manufacturing a specific end product

- Our specialists carry out installation of equipment and perform commissioning works

- Staff training

- Ongoing advice by our technical experts

Technical characteristics

Technical Characteristics of the GFRP silos production line

| Purpose: | production of fiberglass silos |

| Voltage: | 380 V / 50 HZ |

| Power: | 30 kw |

| Line Performance: | Depends on end product |

| Equipment Length: | 12 m |

| Width: | 2.5 m |

| Height: | 2.8 m |

Advantages of FRP silos compared to conventionally used silos:

- Corrosion resistance – GFRP silos are resistant to corrosion resultant from sea water, chemicals, oil, gas, heat, UV rays and extreme environmental conditions.

- Space saving – When it comes to agricultural grain storage, warehouses serve as another option for storage. Nevertheless, this is where silos save much more space by being vertically positioned.

- Zero waste of stored product – Vertical placement of silos means that it is easy to unload the stored product and there is no product waste resultant from lack of internal compartments, shelves, etc.

- Internal temperature, moisture and pressure – FRP silos are built with an internal management system in mind. As a result, all requirements tied to agricultural and oil&gas industry storage are not only followed but also eased, given better primary characteristics of GFRP silo behaviour.

- Sustainability – The end product of our composite silo production lines aids the sustainability in construction, turning the industry towards a more eco friendly solution.

- Durability / Lightweight – High strength makes fiberglass silos resistant to vibration and other internal and external forces applied to the silo. GFRP silos are lightweight as compared to ductile iron, mild steel and HDPE silos. Light weight ensures easy handling, transportation and installation. These qualities make FRP silos much more durable, reliable and economical than conventional silos.

- Inflammation resistance – Unlike its iron counterparts, GFRP silos do not explode and do not catch nor sustain fire.

- Customization options – Suitable for practically every industrial requirement possible.

- Lack of contamination – FRP silos do not rust and therefore carry zero affect to the stored liquids, regardless whether it is water, liquid gas or chemicals.

- Minimal maintenance and repair – Long life expectancy eliminates additional costs ties to repairs.

- Pressure resistance – The high stiffness and high compressive load capacity of FRP silos prevent bursting pressure fluctuations.

- Hydraulic efficiency– GFRP silos have a smooth internal surface which aids excellent hydraulic characteristics and high flow capacity and low friction.

Turn-key GFRP Rebar Production!

By matching your GFRP rebar sales price to steel rebar, you achieve a profit margin of over 120%!

Get your production line in just 2 months after placing an order and return your investment in just 3 months after production launch.

FRP Silo application

FRP silos are commonly used in overground applications where high endurance, hydraulic efficiency and high strength is essential.