Fiberglass Tanks and Silos

Fiberglass Reinforced Plastics (FRP) represent a state-of-the-industry composite material widely used in the construction of tanks and silos of various sizes. The FRP end product is received by reinforcing high-performance fiberglass and several types of resins. Given its durability, heat and corrosion resistance, the material has become a popular choice for manufacturing tanks meant for storing various substances.

To enhance certain properties of FRP tanks and silos, certain grades of resin are used to manufacture silos and tanks for different applications.

More specifically:

– Orthophthalic resin is used for general-purpose tanks and provides containment properties.

– Isophthalic resin provides enhanced wear resistance and chemical resistance. This resin type is used in manufacturing reservoirs and containers for industries where higher corrosion resistance is required.

– Vinyl Ester Resin ensures a higher level of resistance to temperatures and chemical substances for many industrial applications.

Fiberglass tanks

An FRP storage tank is a cylindrical reservoir designed specifically to store various substances and materials. Based on the specific application, fiberglass tanks can be installed both vertically & horizontally above or below the ground.

Main types of fiberglass tanks:

Flat bottom — the most popular and cost-effective solution widely implemented across many industries.

Slope bottom — Slope-bottomed tanks are used when a full drainage is required.

Dish bottom — Dish-bottomed tanks allow partial draining. This type of tanks represents an optimal solution for industries when head pressure is necessary.

Cone bottom — Cone-bottomed tanks are commonly known as silos; these tanks can be totally drained of their contents.

Double-wall tanks — Tanks with double walls are usually used for enhanced safety and reliability.

Fiberglass silos

A fiberglass silo is an FRP container with a specific form factor designed for storing various bulk materials. A typical silo is a cylindrical container with a cone-shaped bottom. Silos are commonly used in the chemical industry, non-ferrous metal manufacture, grain elevators, as well as coal and cement warehouses.

Quite often, silos serve to store raw materials, semi-finished and finished products. For industrial applications, silos can be designed as separate units or a group of interconnected silos within a silo body (modular structure).

Key benefits of fiberglass storage tanks

Besides standard forms and sizes, fiberglass tanks and silos can be custom-designed to satisfy the requirements of commercial and industrial applications.

Fiberglass silos are airtight and lightweight.

Corrosion resistance. Fiberglass storage tanks are resistant to saltwater, UV rays, and acid rain.

High wear-resistance.

Ease of repair and reconfiguration upon custom implementation.

Ease of transportation due to the lighter weight.

Fiberglass tanks & silos outperform tanks and silos made of steel in the following aspects:

Better flow capacity. FRP tanks are produced without joints and multiple bolted parts ensuring a plain and even interior surface and elimination of potential leaks.

Better heat-insulation. Fiberglass is a non-conductive material; hence, it is more condensation-resistant compared to steel.

Better endurance. Due to the wear-resisting properties of fiberglass, GFRP tanks and GFRP silos have a long-life performance compared to their steel counterparts.

A high level of corrosion resistance means less maintenance and higher endurance.

Versatile applications

Fiberglass tanks and silos are widely implemented above and below the ground across many industries, such as agriculture, food processing industry, chemical industry, oil & gas, fire suppression, etc.

Above the ground:

· Food and beverage Industries

· Industrial chemicals

· Energy and utilities (oil field storage)

· Agriculture (liquid fertilisers, irrigation water, etc.)

· Water and wastewater (sewage sludge)

· Fire suspsion

Below the ground:

· Motor oil

· Fire suspension

· Rainwater collection

· Water and corrosive liquids

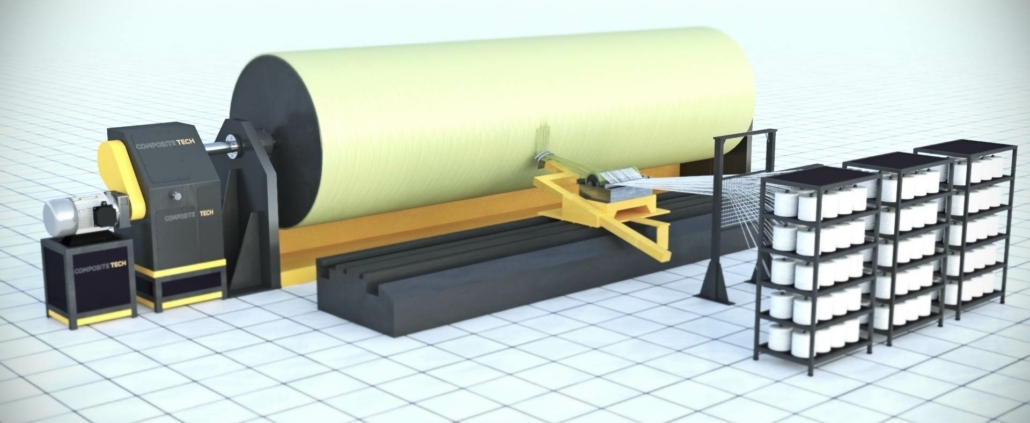

Final Words on Fiberglass Reinforcement

In the past 10 years, Composite-Tech has been perfecting the manufacturing technology to ensure the supreme quality of its production lines that manufacture fiberglass storage tanks. As of now, the company is one of the major suppliers of fiberglass tanks & silos and GFRP production lines. The company also specialises in GFRP rebar and mesh production lines, shipping this range of industrial grade GFRP production equipment globally.