The production of fiberglass rebar, known as GFRP (Glass Fiber Reinforced Plastics) rebar, is a sophisticated process that integrates advanced technology with specialized materials to produce reinforcement bars with superior strength and durability. This article delves into the intricate production process of FRP rebar by Composite-Tech, highlighting its unique aspects that set it apart from traditional steel reinforcement and other competitors in the market.

Content

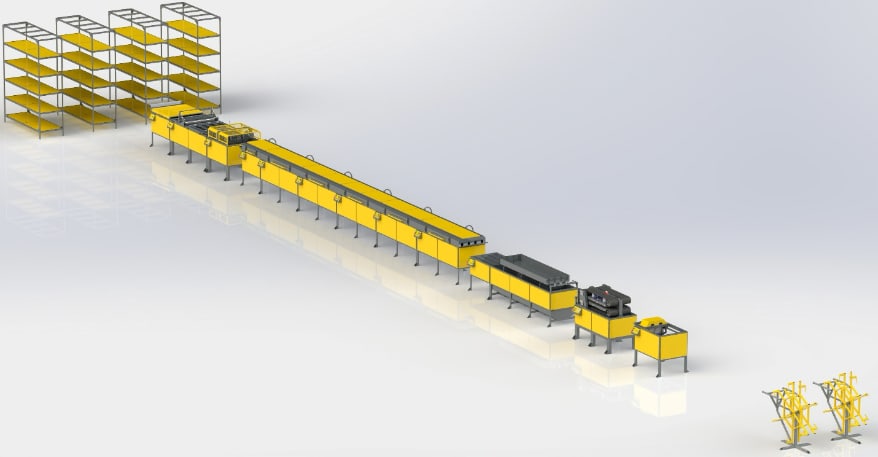

Learn more about FRP REBAR production line CT4

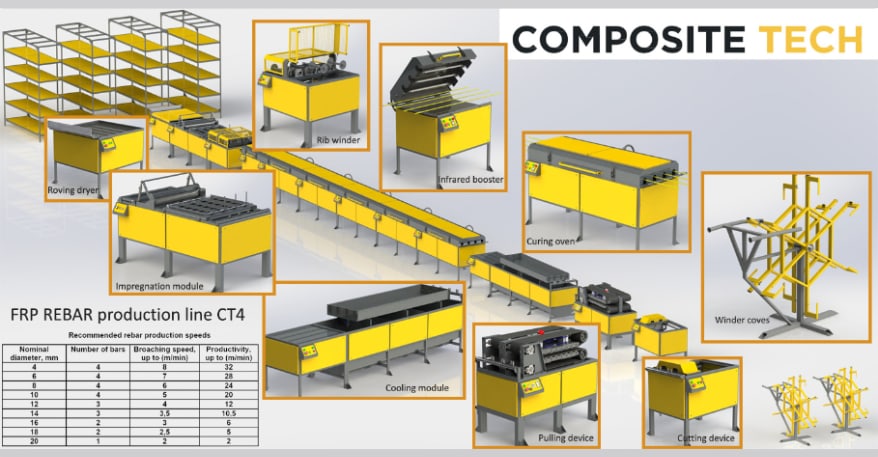

The Beginning: Material Preparation

The journey of creating FRP rebar begins with the preparation of raw materials. Composite-Tech uses specialized racks to store spools of glass or basalt fiber rovings. These fibers are the backbone of FRP rebar, providing its core strength. The choice between glass and basalt fibers depends on the specific application requirements, including tensile strength, durability, and environmental resistance.

Degreasing: The Key to Bonding

A critical step in the production process is the degreasing of the fibers. During manufacturing, a lubricant is applied to the rovings to facilitate their processing. However, this lubricant must be removed to ensure the best possible bond between the fibers and the resin. Composite-Tech employs a meticulous degreasing process, where the lubricant is evaporated, leaving microscopic spaces between the fibers. These spaces are crucial as they are later filled with resin, significantly enhancing the final product’s strength.

Resin Impregnation: Ensuring Maximum Saturation

Following degreasing, the fibers undergo a resin impregnation process. This step is essential for coating each fiber with a binding resin that holds the rebar together and provides chemical resistance. Composite-Tech utilizes a combination of ultrasonic waves and mechanical processes to ensure that each fiber is thoroughly saturated with resin. Additionally, this stage involves the expulsion of air from the raw rebar, a factor critical to preventing voids that could compromise the rebar’s structural integrity.

Shaping and Ribbing: Customizing Adhesion

After impregnation, the rebar is shaped and ribbed. Composite-Tech’s equipment is designed to adjust the angle of rib application, allowing for the production of rebar with customized rib angles. This capability is significant because it enhances the adhesion of the rebar to concrete, improving the composite material’s overall effectiveness in reinforcement applications.

Polymerization: A Patented Technique

The polymerization oven is where the FRP rebar acquires its final properties. Composite-Tech has developed a patented polymerization process that initiates from the inside of the rebar outward. This method contrasts sharply with competitors’ techniques, which typically polymerize from the outside in, leading to potential surface damage and reduced product quality. Composite-Tech’s approach ensures a uniformly cured product with superior strength and longevity.

Cooling: Preventing Thermal Shock

The final step in the manufacturing process is cooling, another patented process by Composite-Tech. The company employs an air cooling method followed by water cooling to gradually reduce the temperature of the rebar. This controlled cooling process prevents thermal shock, which could cause cracking and compromise the integrity of the GFRP rebar. In contrast, competitors often rely solely on water cooling, which can lead to inferior product quality due to the abrupt temperature change.

Conclusion: Trust in Professionalism

Composite-Tech’s industrial-grade production line for FRP rebar embodies the pinnacle of current technology and innovation in the field of composite materials. By meticulously controlling every step of the rebar manufacturing process, from material preparation to the final cooling, Composite-Tech ensures that its FRP rebar meets the highest standards of quality and performance. This dedication to excellence makes Composite-Tech’s products a preferred choice for professionals seeking reliable, durable, and efficient reinforcement solutions. Trust in the professionals, and choose Composite-Tech for your industrial-grade GFRP rebar needs.