The End of the Steel Era in Infrastructure

For nearly 100 years, steel rebar dominated infrastructure construction in the United States. From bridges and highways to marine structures and tunnels, steel shaped modern America.

But time and science have revealed steel’s irreversible weakness: corrosion.

Today, corrosion-related failures cost the U.S. economy over $22 billion annually, according to the Federal Highway Administration.

Saltwater exposure, freeze-thaw cycles, chemicals in concrete, and environmental conditions steadily attack steel — weakening structures from within.

And as America launches the largest infrastructure spending plan in modern history — over $1.2 trillion under the Infrastructure Investment and Jobs Act — engineers and developers are facing one critical question:

Why continue building the future with materials designed for the past?

The Rise of FRP — A New Era of Smart Reinforcement

What is FRP Rebar?

FRP (Fiber Reinforced Polymer) rebar — primarily GFRP (Glass Fiber Reinforced Polymer) — is a corrosion-proof, high-strength composite reinforcement designed to replace steel in concrete structures.

Key Performance Advantages

| Property | Steel | GFRP Rebar |

| Corrosion Resistance | Corrodes | 100% corrosion-proof |

| Tensile Strength | ~60 ksi | 120–200 ksi (2–3× stronger) |

| Weight | Heavy | 4× lighter |

| Thermal Conductivity | Conductive | Non-conductive (EM-safe) |

| Magnetic Interference | Yes | None — MRI & radar safe |

| Service Life | 20–50 years | Up to 100+ years |

Result: Less maintenance, longer lifespan, safer structures, lower lifetime cost.

Why America Needs FRP Now

Coastal & Marine Infrastructure

From Florida to California, salt exposure destroys steel-reinforced concrete.

FRP does not rust — ever.

- Coastal bridges

- Seawalls & ports

- Wastewater plants

- Desalination facilities

Transportation & Bridges

The U.S. Department of Transportation reports over 42,000 bridges structurally deficient.

FRP extends service life and reduces rehabilitation costs.

Military & Critical Defense Structures

FRP is non-conductive and non-magnetic — essential for radar systems, data centers, and defense installations.

Clean Energy & EV Infrastructure

New-generation battery plants, hydrogen facilities, and energy hubs require non-corrosive, non-conductive reinforcement.

Compliance with U.S. Engineering Standards

Modern GFRP rebar complies with major U.S. codes:

| Standard | Description |

| ACI 440.11-22 | FRP Rebar Design Code |

| ASTM D7957 | Standard Spec for GFRP |

| FDOT Approval | For Florida construction |

| CSA S806 | North American design code |

Composite-Tech equipment is engineered to manufacture FRP products that meet — and exceed — these specifications.

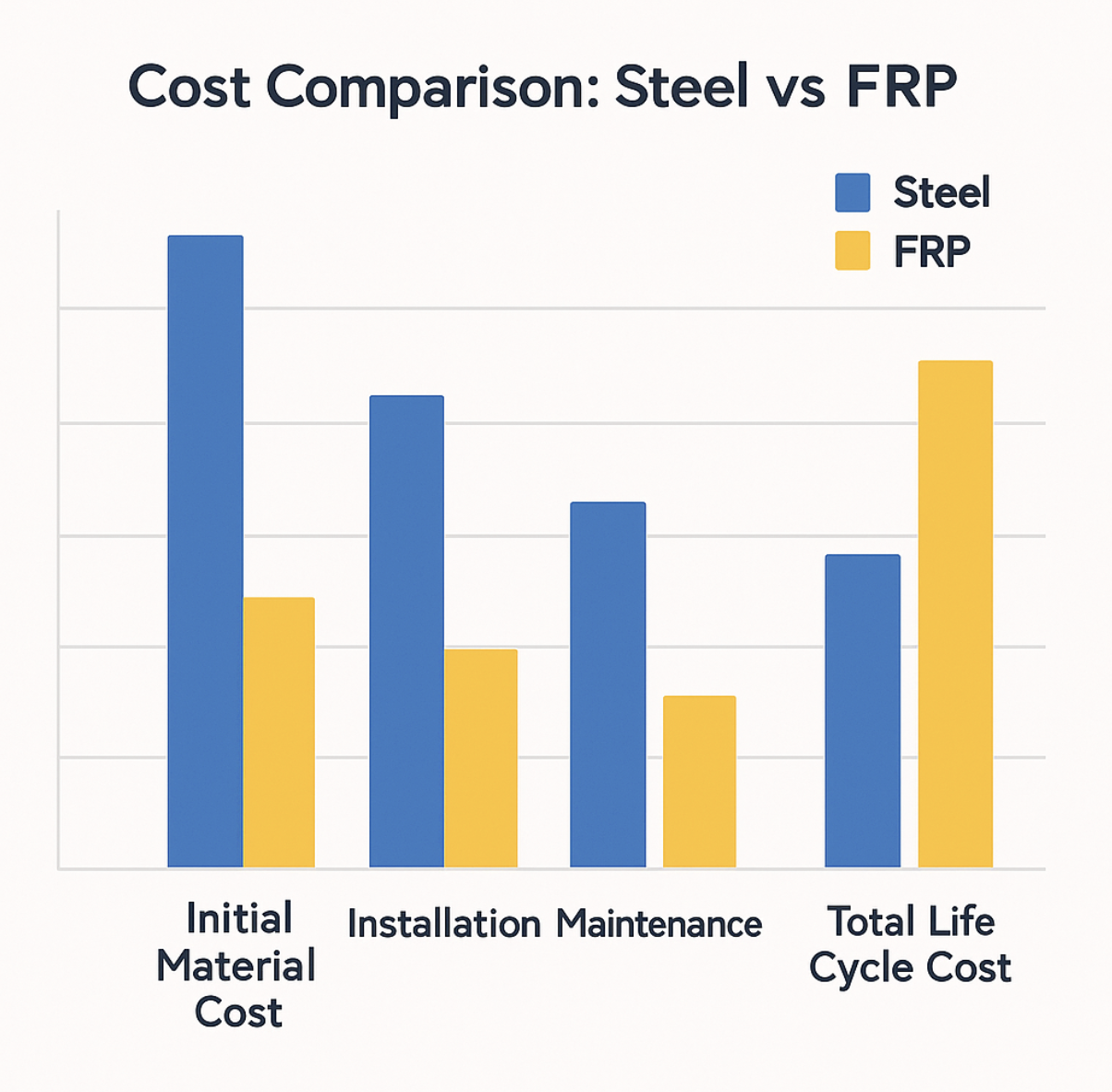

Cost Analysis: Steel vs FRP

Traditional conversation:

“Steel is cheaper per ton.”

Modern reality:

Lifetime cost > Purchase cost.

| Cost Category | Steel | FRP |

| Initial Material Cost | Lower | Slightly higher |

| Installation | Requires heavy equipment | Lightweight = faster & cheaper |

| Maintenance | High (corrosion repair) | Near-zero |

| Service Life | 20–50 years | 80–100+ years |

| Total Life Cycle Cost | High | Lowest |

Conclusion: FRP wins on lifecycle economics — the metric that matters most to government projects and large infrastructure developers.

Why Manufacturers Choose Composite-Tech

Modern FRP adoption in America is not just demand-driven — it is technology-driven.

Composite-Tech equipment ensures:

- ACI/ASTM-compliant quality

- Automated manufacturing (24/7 operation)

- Precise fiber alignment

- Consistent resin impregnation

- Perfect curing control

- Stable diameter calibration

And most importantly?

Guaranteed production parameters tested to meet U.S. standards.

Real-World Success Stories

Florida, USA — Coastal FRP Factory

- Extreme salt exposure region

- FRP selected to replace steel in marine infrastructure

- Composite-Tech lines produce high-volume rebar 24/7

India — Large-Scale FRP Expansion

- Government push for corrosion-proof infrastructure

- Composite-Tech systems chosen for scalability and precision

- Serves highways, metro tunnels, and industrial projects

Engineers choose us not only for performance — but for partnership, training, and standards support.

Looking Ahead — Graphene-Enhanced FRP

Composite-Tech is advancing GFRP into the next generation:

Graphene-reinforced composite rebar.

Benefits:

- Increased tensile strength

- Crack-bridging ability

- Enhanced durability

- Emerging conductivity control applications

This innovation positions FRP as the ultimate reinforcement technology for the next century of American infrastructure.

Conclusion

Steel served the world for a century. FRP will power the next one.

The United States is entering a new era of infrastructure — smarter, more durable, and environmentally responsible.

FRP is not just a better material — it is the new standard.

Ready to start manufacturing FRP rebar in the United States?

Composite-Tech provides turnkey production solutions, installation, training, and certification support.

Request your FRP factory ROI plan

Schedule a technical consultation

Learn more:

- How to Install Fiberglass (GFRP) Rebar in Concrete Slabs

- From Florida to India: How Composite-Tech Machines Empower Global FRP Leaders

- Why Composite-Tech and FRP Institute Are Defining the Global Standards for Composites

- ACI 440.11-22 Explained: How to Design Concrete with GFRP Rebar in the U.S.

- Understanding ACI 440.11-22 for GFRP Rebar Manufacturers

- Graphene in GFRP Rebar Production: A Revolution in Concrete Reinforcement

- #3 (3/8 in) Fiberglass Rebar: Real U.S. Pricing, Weight, and Use-Cases

- Why Composite-Tech Is the Global Leader in GFRP Production Equipment

- GFRP Rebar vs Steel: Cost, Strength, and Long-Term Benefits in Modern Construction

- GFRP Rebar vs Steel Rebar: A Complete Technical Comparison

- Can Fiberglass Rebar Replace Steel in Foundations and Driveways?