Key Takeaways

- Composite-Tech is a pioneer in composite rebar technology, with more than 15 years of experience, delivering solutions to dozens of countries.

- Composite-Tech’s innovative rebar equipment is the only solution in the world that enables the production of GFRP bent elements with industrial precision and efficiency.

- By investing in Composite-Tech’s FRP stirrup production line, American manufacturers and contractors gain access to an exclusive technology that cannot be replicated elsewhere.

A Breakthrough in Construction Technology

In the rapidly evolving construction industry, innovation is no longer an option – it is a necessity. From infrastructure renewal to advanced building technologies, the demand for stronger, lighter, and more durable materials continues to rise. One of the most revolutionary developments is Glass Fiber Reinforced Polymer (GFRP), which has already proven to outperform traditional steel reinforcement in many applications.

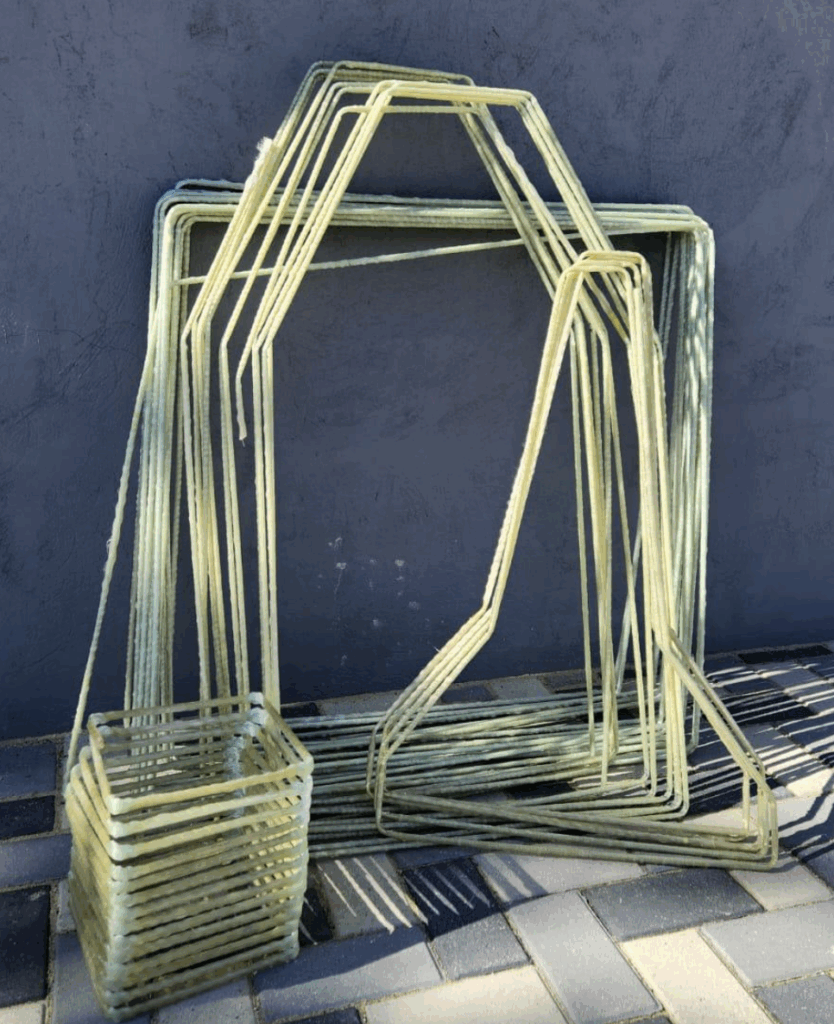

While many companies around the world manufacture straight GFRP rebars, only Composite-Tech has developed unique equipment for producing GFRP bent elements – a technology that has no analogues anywhere in the world. This GFRP bent elements machine is a true game-changer, enabling the production of stirrups, hooks, curved rebars, and other custom-shaped elements that significantly expand the application range of composite reinforcement.

This article explores why this technology is unmatched, why it is critically important for the U.S. construction industry, and why Composite-Tech is the global leader in innovative rebar equipment.

The Problem with Traditional Technologies

For decades, steel has been the default choice for concrete reinforcement. However, traditional steel reinforcement presents a number of well-known problems:

- Corrosion: Steel corrodes when exposed to moisture, chemicals, and salts. This drastically reduces the service life of infrastructure such as bridges, highways, and marine structures.

- Heavy weight: Steel is heavy, increasing transportation and installation costs.

- Magnetic interference: Steel can interfere with sensitive electronic equipment, limiting its use in certain structures like hospitals, airports, and laboratories.

- Limited durability in extreme environments: In coastal areas, tunnels, and wastewater plants, steel reinforcement often fails prematurely.

While straight GFRP rebars have already become a preferred alternative in many applications, the inability to mass-produce bent composite elements has limited their use in projects where stirrups and curved reinforcement are necessary. Until now.

Learn more:

Why the U.S. Market Needs This Technology

The United States is currently facing a critical challenge: aging infrastructure. According to the American Society of Civil Engineers (ASCE), more than 42% of U.S. bridges are over 50 years old, and many highways, tunnels, and water management facilities are reaching the end of their service life.

The adoption of GFRP construction technology in the USA can significantly extend the durability of infrastructure. Bent elements are especially crucial for:

- Seismic reinforcement in earthquake-prone regions like California.

- Bridge and highway construction, where stirrups and hooks are essential.

- Coastal infrastructure, where corrosion-resistant bent rebar prevents structural failures caused by saltwater.

- Nuclear and medical facilities, where non-magnetic reinforcement is critical.

With the Composite-Tech bent rebar equipment, American engineers can now design and build projects that last over a century, without the high maintenance costs of steel-based solutions.

Composite-Tech GFRP Bent Elements Machine: Unique Features

Unlike conventional bending methods, Composite-Tech has engineered the world’s only industrial-grade composite rebar bending machine specifically designed for GFRP.

Key technical features:

- Precision automation – fully computerized control ensures consistent geometry of every stirrup or hook.

- High productivity – capable of producing hundreds of bent elements per hour.

- Material integrity – bending without damaging fibers, maintaining maximum tensile strength.

- Durability – designed for continuous industrial operation with minimal maintenance.

- Customization – adjustable for various diameters, bend radii, and element shapes.

This is not just a machine – it is a patented technology, backed by decades of engineering expertise and over 100 patents held by Composite-Tech worldwide.

Advantages of GFRP Bent Elements Over Steel

The benefits of composite reinforcement are well-documented in numerous research studies. When combined with advanced bending technology, GFRP bent elements provide unmatched advantages:

| Property | Steel Rebar | GFRP Bent Elements |

| Service life | 20–40 years (with corrosion risk) | 100+ years (corrosion-resistant) |

| Weight | Heavy (7.8 g/cm³) | 4–5 times lighter (1.9 g/cm³) |

| Corrosion resistance | Prone to rusting | 100% corrosion-resistant |

| Strength-to-weight ratio | Moderate | Very high |

| Installation costs | High (requires heavy lifting) | Reduced (easy handling) |

| Magnetic/electrical neutrality | Conductive & magnetic | Non-conductive, non-magnetic |

In real-world terms, this means lighter transportation, faster installation, longer durability, and significant cost savings for American contractors and government infrastructure projects.

Why Composite-Tech is the Global Leader

Composite-Tech is not just another machinery supplier. The company is a pioneer in composite rebar technology, with more than 15 years of experience, delivering solutions to dozens of countries.

Unique advantages of Composite-Tech:

- Over 100 international patents protecting innovative equipment designs.

- Dedicated R&D team of engineers specializing in composites.

- Export presence in North America, Europe, Asia, and the Middle East.

- Trusted by leading construction companies worldwide, including large infrastructure projects.

- Comprehensive training and support, ensuring smooth integration of technology into production.

By investing in Composite-Tech’s FRP stirrup production line, American manufacturers and contractors gain access to an exclusive technology that cannot be replicated elsewhere.

Learn more: Why Composite-Tech Is the Global Leader in GFRP Production Equipment

The Future of Construction: From Steel to GFRP

The U.S. government is allocating billions of dollars to modernize infrastructure under programs such as the Infrastructure Investment and Jobs Act (IIJA). This presents a historic opportunity for the adoption of advanced composite materials.

The transition from steel to corrosion-resistant bent rebar will:

- Reduce life-cycle costs of infrastructure projects.

- Extend service life by decades.

- Minimize disruptions caused by premature structural failures.

- Contribute to sustainable and eco-friendly construction.

Composite-Tech’s composite rebar bending machine is the key technology that makes this transition possible on an industrial scale.

Conclusion: A Call to Action for U.S. Companies

The future of reinforcement technology is here, and it is happening now. Composite-Tech’s innovative rebar equipment is the only solution in the world that enables the production of GFRP bent elements with industrial precision and efficiency.

For U.S. construction companies, manufacturers, and investors, this represents a unique opportunity:

- Be the first in the American market to adopt a technology with no analogues.

- Offer corrosion-free, lightweight, and long-lasting solutions to clients.

- Participate in the transformation of U.S. infrastructure for the next 100 years.

Contact Composite-Tech today to learn how you can implement this groundbreaking technology, purchase equipment, and bring the future of construction to the United States.

Learn more: