Advancing U.S. Infrastructure with GFRP Rebar: Applications, Regulations, and Market Opportunities

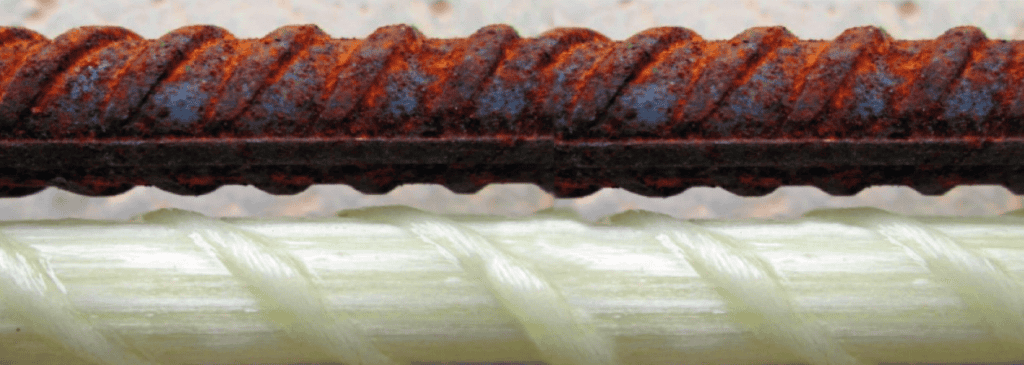

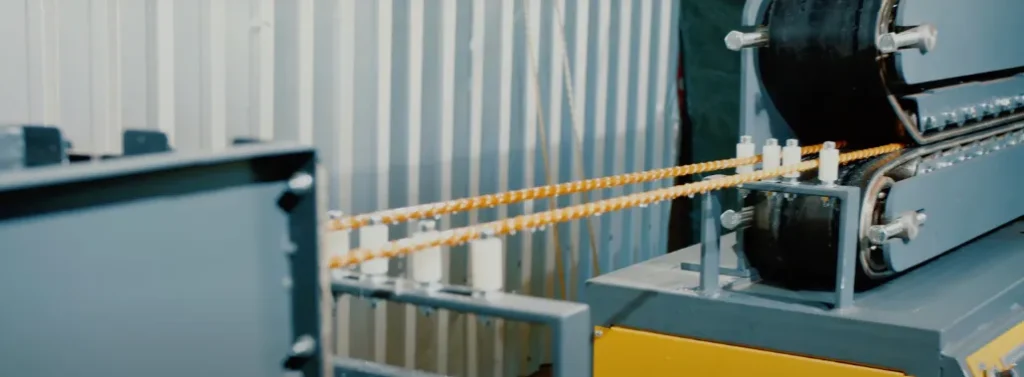

Glass Fiber Reinforced Polymer (GFRP) rebar is revolutionizing the U.S. construction industry by offering superior corrosion resistance, lightweight properties, and high tensile strength.