The Hidden Carbon Cost of Steel

Concrete and steel — the two pillars of modern construction — are also two of the world’s largest sources of CO₂ emissions.

According to the World Steel Association, steel manufacturing alone generates around 7–9% of total global CO₂ emissions. Every ton of rebar produced emits nearly 1.9 tons of CO₂ into the atmosphere.

When embedded in concrete, steel’s corrosion creates another hidden cost:

- Maintenance, demolition, and replacement cycles every 20–40 years.

- Each replacement generates additional emissions from cement, transport, and energy.

That means every steel-reinforced bridge, tunnel, or building contributes to a carbon debt that compounds over decades.

FRP: The Sustainable Alternative

FRP (Fiber-Reinforced Polymer) rebar — and specifically GFRP (Glass Fiber Reinforced Polymer) — is emerging as a sustainable solution that directly cuts carbon emissions across the entire construction lifecycle.

Unlike steel, FRP does not corrode, does not require protective coatings, and lasts far beyond 80–100 years.

This alone translates into significant emission savings — but the environmental benefits go much deeper.

1. Lower Energy & Emission Footprint During Manufacturing

Producing FRP requires:

- No smelting,

- No high-temperature furnaces,

- No fossil-fuel reduction processes.

While steelmaking demands temperatures of >1500 °C, FRP is produced at under 200 °C using electric-powered polymerization.

According to data from the European Composites Industry Association (EuCIA), FRP manufacturing emits 60–70% less CO₂ per ton than traditional rebar production.

2. Lightweight = Lower Transportation Emissions

FRP weighs about 4 times less than steel, meaning:

- Fewer trucks per shipment

- Lower fuel consumption

- Reduced site handling and crane energy

For large infrastructure projects, this can translate into emission reductions of 15–25 tons of CO₂ per 1 000 tons of rebar shipped.

3. Durability = Fewer Replacements

Most of the carbon footprint in infrastructure comes not from building — but from rebuilding.

Steel-reinforced concrete typically lasts 25–40 years before corrosion demands major repair or replacement.

FRP’s 100-year service life eliminates up to two full reconstruction cycles, cutting:

- Cement production emissions

- Demolition waste

- Transportation and landfill CO₂

In life-cycle terms, FRP can reduce the total CO₂ impact of a structure by 30–45%.

4. No Corrosion = Cleaner Environment

Corroded steel leaches heavy metals into soil and groundwater.

FRP contains no iron or toxic components — making it chemically neutral and safe for water infrastructure, desalination plants, and coastal foundations.

5. Electrification Compatibility

FRP’s non-conductive nature makes it ideal for:

- Renewable energy facilities

- Hydrogen production plants

- Electric vehicle infrastructure

It eliminates electromagnetic interference and allows integration with renewable materials, which supports LEED and Envision sustainability certifications.

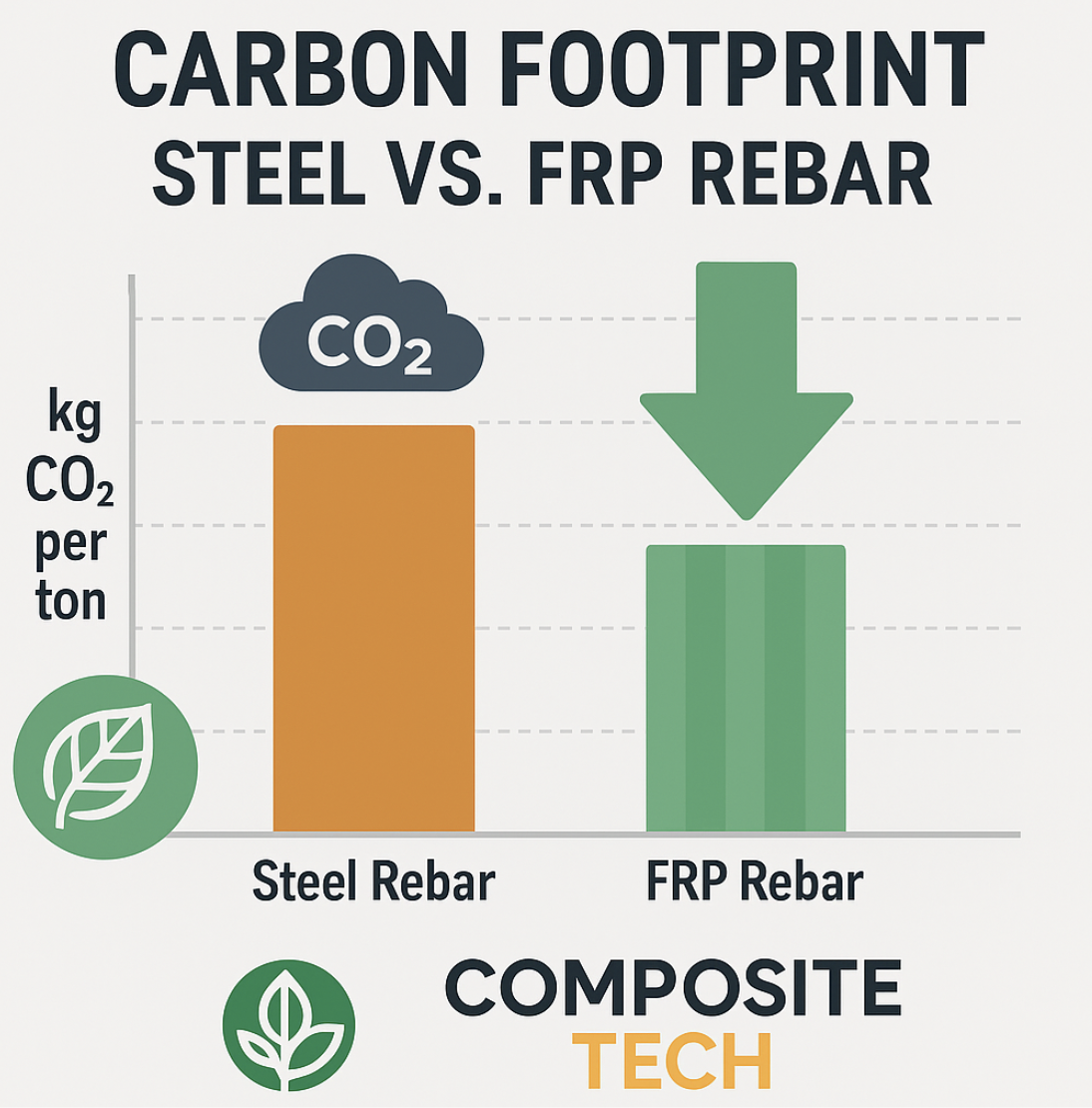

6. Quantified Environmental Impact

A 2023 Life Cycle Assessment (LCA) by the University of Sherbrooke (Canada) compared FRP and steel rebar under identical design loads:

| Metric | Steel Rebar | FRP Rebar |

| CO₂ Emissions (per ton) | 1.9 t | 0.6–0.8 t |

| Energy Use (kWh/ton) | 8 000–10 000 | 2 400–3 000 |

| Average Service Life | 40 years | 100+ years |

| Maintenance Emissions | High | Negligible |

| Corrosion Waste | 5–7% of total weight | 0% |

The study concluded that substituting FRP for steel can reduce total lifecycle GHG emissions by up to 63%.

Composite-Tech: Engineering Eco-Reinforcement for the World

Composite-Tech’s production lines are designed for maximum efficiency and minimal waste:

- Fully electric curing ovens with smart energy control

- Optimized resin usage for zero material loss

- Recyclable process water and low-VOC resins

Each FRP rebar or mesh produced on a Composite-Tech line saves hundreds of kilograms of CO₂ compared to its steel counterpart.

“Eco-reinforcement is not just a marketing term — it’s measurable carbon reduction in every meter of rebar we produce.”

— Anton Ocunev, CEO, Composite-Tech

A New Standard for Sustainable Infrastructure

As nations aim for Net Zero 2050, sustainable reinforcement technologies like FRP are no longer optional — they are essential.

Governments and engineering firms across the U.S., Europe, and Asia are already including FRP in green building codes and environmental performance tenders.

Every FRP factory built today accelerates this transition — creating local jobs, reducing imports, and helping the planet breathe easier.

Conclusion: Building Stronger and Greener

Replacing steel with FRP rebar is one of the most practical, immediate, and measurable ways to reduce the carbon footprint of construction.

Composite-Tech is proud to lead this transition — combining European engineering, global reach, and a clear ecological mission:

To build infrastructure that serves generations — not decades.

Ready to make your construction business more sustainable?

Contact Composite-Tech to learn how FRP technology can reduce your project’s carbon footprint and increase its lifetime ROI.

Learn more: