Composite-Tech GFRP rebar production lines manufacturing

About us

Composite-Tech is globally known for taking construction materials and production lines to the next level. We re-imagine existing and commonly used steel rebar and production methods in favour of reinforcement, cost and production effectiveness, quality and transportation benefits. It is this that led us to creating fiberglass and basalt rebar manufacturing lines and for the past 10 years we have been perfecting this technology to the level of a turn-key solution. Our composite production technology is developed in partnership with universities and regulators from the USA, Canada, Japan, Russia, Italy and the Netherlands. Today, we supply our fiberglass/basalt rebar, mesh and bent elements production lines globally and make the world of construction new age, more secure and immune to affects of time and weather. It is a highly profitable business that requires minimum investment and short payback period.

How to start composite FRP rebar production?

Planning to start composite rebar production but don’t know how? Well, we are here to help because our FRP rebar, mesh and bent elements production lines can get you started. Moreover, you will be starting with the most technologically advanced, fully automated production lines on the market. Under full production load our clients return their investment in just 4 months after launch and we give 1 year warranty on all modules that comprise full production line.

Benefits of composite/FRP rebar greatly outweigh characteristics of steel rebar and therefore most constuction companies in the world have already started to shift their preferences towards FRP products.

FRP rebar vs steel rebar:

– FRP is corrosion free (great solution for coastal structures)

– It is much stronger,

– Raw materials do not increase in price like steel does (steel has doubled in price in the last year).

– FRP rebar does not conduct electricity (perfect for factories, hospitals, airports, underground).

– Composite rebar is 8 times lighter than steel rebar (transport more).

Our certifications

Turn-key GFRP Rebar Production!

By matching your GFRP rebar sales price to steel rebar, you achieve a profit margin of over 120%!

Get your production line in just 2 months after placing an order and return your investment in just 3 months after production launch.

Applications

Roads & Highways

Bridges & Tunnels

Airports,Ports and Railways Stations

Metro Rail and Railways

Real Estate

Industrial

Hospitals and Research Centres

School and Universities

Warehousing

Large Infrastructure Project like Dams, Power & Plants

CONSTRUCT EXPO 2016

FIBERGLASS MESH IN ROAD PAVING

FIBERGLASS REINFORCEMENT IN INDUSTRIAL FLOORS

COMPOSITE REINFORCEMENT BARS IN HIGHWAY CONSTRUCTION

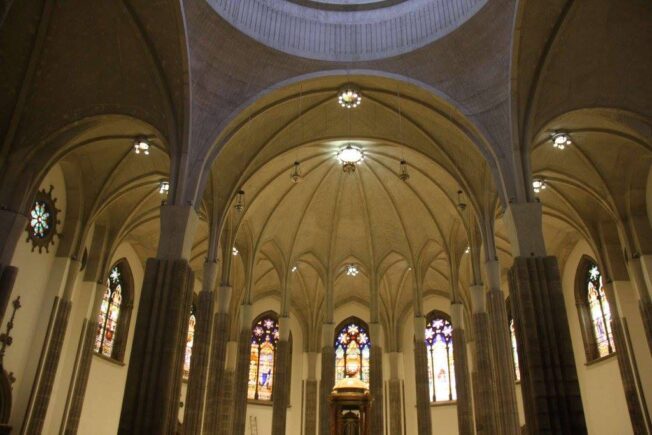

COMPOSITE REINFORCEMENT BARS IN CHURCH CONSTRUCTION

USE OF COMPOSITE RODS IN METRO LINES

We supply equipment and products to more than 23 countries

USA

ACI 440.1R:

Guide for the Design and Construction of Structural Concrete Reinforced with FRP Bars AASHTO LRFD: Bridge Design Specifications for GFRP- Reinforced Concrete Bridge Decks and Traffic Railing

EUROPE

FIB Task Group

9.3 – Bulletin 40 – FRP Reinforcement in

RC Structures

CANADA

ACI 440.1R:

Guide for the Design and Construction of Structural Concrete Reinforced with

FRP Bars

SAUDI ARABIA

ACI 440.1R:

Guide for the Design and Construction of Structural Concrete

Reinforced with

FRP Bars

INDIA

AASHTO (2018), FDOT / 2021, SA/2006. Ac1440 As per Indian Road

Congress

PARAGUAY

NORMA PARAGUAY

NP 17 09 1 19

SWITZERLAND

FIB BULLETIN NO. 40

NORWAY

22-A 98741

Structural-Eurocrete Modifications to Ns3473 when using FRP Reinforcement.

ITALY

CNR DT 203/2006

Structural-Guide for the Design and

Construction of Concrete Structures

Reinforced with Fiber- Reinforced Polymer Bars.

UKRAINE

NBV 2.6-185-2012

Structural-Guidelines for the design and manufacture of concrete sructures with non-metallic composite reinforcement on the basis of basalt and glass fiber rovings

REP. OF BELARUS

1103-98

Structural-Glass-fiber plastic reinforcement. Technical requirements

JAPAN & CHINA

NO. 30

JAPAN-CONCRETE ENGINEERING SERIES 23

Structural-Recommendation for design and construction of concrete

structures using continuous fiber reinforcing materials (Design)

RUSSIA

GOST 31938-2012