Rewolucja w zakresie wzmacniania

Od ponad wieku stal stanowi podstawę nowoczesnej infrastruktury. Jednak korozja, waga i wyzwania związane ze zrównoważonym rozwojem zmuszają inżynierów do ponownego przemyślenia przyszłości zbrojenia.

Wchodzić GFRP (polimer wzmocniony włóknem szklanym) — materiał lżejszy, mocniejszy, niekorozyjny i odporny na degradację chemiczną.

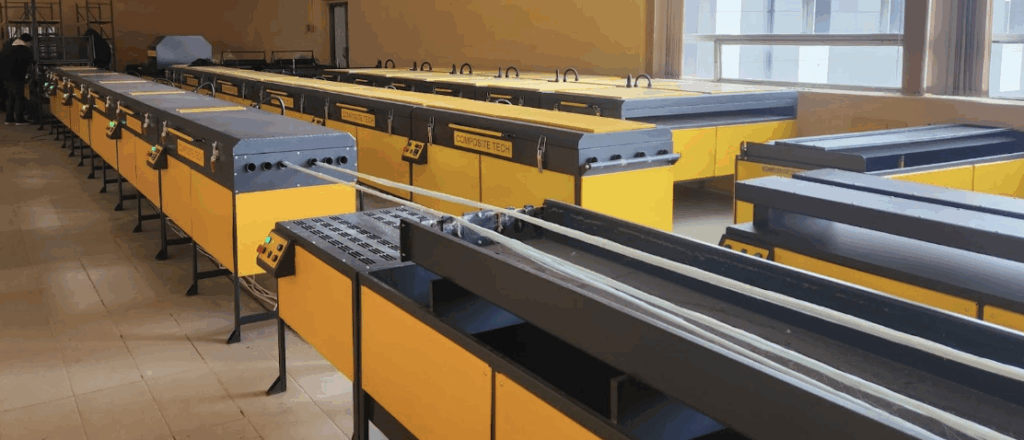

W centrum tej globalnej zmiany stoi Composite-Tech, europejski producent zaawansowanego sprzętu do produkcji prętów zbrojeniowych FRP, siatek i elementów giętych — zaprojektowanych, przetestowanych i skonstruowanych tak, aby spełniały najwyższe światowe standardy.

„Nasza misja jest prosta — zbudować przyszłość wzmocnień. Taką, która będzie trwalsza, lżejsza i będzie chronić planetę”.

— Anton Ocunev, dyrektor generalny Composite-Tech

Od stali do inteligentnego zbrojenia

Sama korozja kosztuje gospodarkę USA ponad $22 miliardy rocznie (Departament Transportu USA).

Tradycyjne pręty zbrojeniowe tracą do 40% swojej wytrzymałości na rozciąganie w ciągu 10 lat w agresywnych środowiskach, takich jak obszary przybrzeżne i mosty.

Z drugiej strony FRP:

- Ma wytrzymałość na rozciąganie 2,5x wyższa niż stal

- Waży 4x mniej

- Jest complettely odporny na korozję

- Ma żywotność 80–100 lat bez degradacji

Dlatego duże projekty infrastrukturalne – od mostów na Florydzie po tunele w Kalifornii – są obecnie projektowane z myślą o Wzmocnienie FRP zgodnie z ACI 440.11-22 I ASTM D7957.

Precyzja inżynierska wyprodukowana w Europie

W przeciwieństwie do taniego sprzętu ręcznego, Maszyny Composite-Tech są zaprojektowane z Europejska precyzja inżynierska I w pełni zautomatyzowana kontrola procesu.

Każdy system zapewnia:

- Idealne ułożenie włókien

- Jednolita impregnacja żywicą

- Stała temperatura utwardzania

- Automatyczna kalibracja średnicy

Ta precyzja jest gwarancją, że każdy Pręty zbrojeniowe FRP wyprodukowane na linii Composite-Tech spełniają najsurowsze normy wydajności mechanicznej wymagane w Rynek amerykański.

Badania, testy i certyfikacja

Każda nowa linia opracowana przez Composite-Tech przechodzi kompletny cykl testów:

- Badania odporności termicznej (−40°C do +200°C)

- Weryfikacja wytrzymałości na rozciąganie i zginanie

- Analiza ekspozycji chemicznej i UV

Trwająca współpraca Composite-Tech z Instytut FRP (USA) zapewnia, że wszystkie parametry sprzętu i produkcji pozostają zgodne z najnowsze normy ACI i ASTM, tworząc przejrzysty i możliwy do prześledzenia proces zapewnienia jakości.

Zrównoważony rozwój jako wartość podstawowa

Oprócz wydajności, podstawą filozofii Composite-Tech jest zrównoważony rozwój.

Umożliwiając zastąpienie stali niekorodującym tworzywem wzmacnianym włóknem szklanym (FRP), firma przyczynia się do redukcji:

- Emisja CO₂ z produkcji stali

- Koszty konserwacji i wymiany przez 70%

- Odpad betonowy z powodu pogarszającej się infrastruktury

FRP to nie tylko alternatywa — to konieczność środowiskowa w XXI wieku.

Globalny zasięg, lokalny wpływ

Maszyny Composite-Tech pracują już w ponad 20 krajów, w tym:

🇺🇸 USA🇮🇳 Indie 🇿🇦 Republika Południowej Afryki 🇷🇴 Rumunia 🇪🇸 Hiszpania 🇨🇦 Kanada

Od małych lokalnych startupów po dużych dostawców materiałów budowlanych, klienci wybierają Composite-Tech ponieważ każda maszyna jest:

- Gotowy na zgodność z ACI/ASTM

- Zbudowany do ciągłej produkcji 24/7

- Wsparcie poprzez instalację na miejscu i szkolenie

Przyszłość: grafen i inteligentne kompozyty

Zespół badawczo-rozwojowy Composite-Tech jest obecnie w trakcie integracji grafen nanotechnologia do prętów zbrojeniowych GFRP — poprawiając przewodność, wytrzymałość i odporność na mikropęknięcia.

Ta nowa generacja wzmocnień wkrótce zdefiniuje na nowo sposób, w jaki inżynierowie projektują trwałe konstrukcje mostów, autostrad i infrastruktury energetycznej.

Wnioski: Inżynieria przyszłości

Composite-Tech łączy Doskonałość produkcji europejskiej, naukowa precyzja, I wizja zrównoważonego budownictwa.

Każda maszyna jest owocem dziesięcioleci badań i jasno określonej misji — pomocy firmom na całym świecie w budowaniu silniejszych, mądrzejszych i bardziej ekologicznych rozwiązań.

Gotowy na budowę własnej fabryki FRP?

Poproś o spersonalizowaną analizę zwrotu z inwestycji i dowiedz się, jak Composite-Tech możemy pomóc Ci uruchomić produkcję w ciągu 60 dni.

Kontakt nasz zespół inżynierów

Dowiedz się więcej:

- Composite-Tech i FRP Institute ogłaszają strategiczne partnerstwo w celu zdefiniowania na nowo globalnych standardów w branży zbrojenia FRP

- Dlaczego Composite-Tech i FRP Institute wyznaczają globalne standardy dla materiałów kompozytowych

- Zyskowność działalności produkcyjnej prętów zbrojeniowych i siatek GFRP w USA

- Composite-Tech: światowy lider w produkcji urządzeń do produkcji prętów zbrojeniowych, siatek i materiałów kompozytowych z włókna szklanego