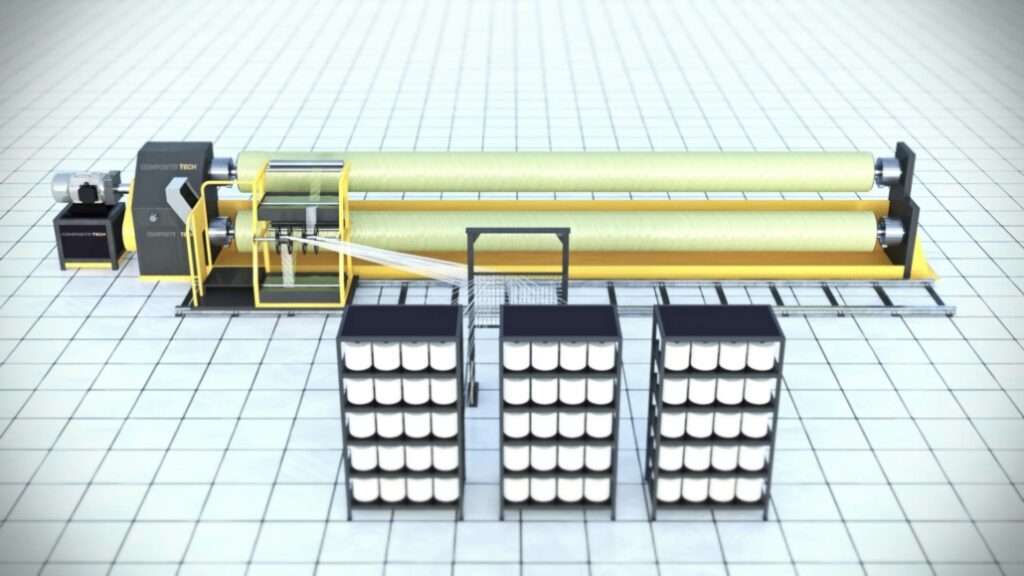

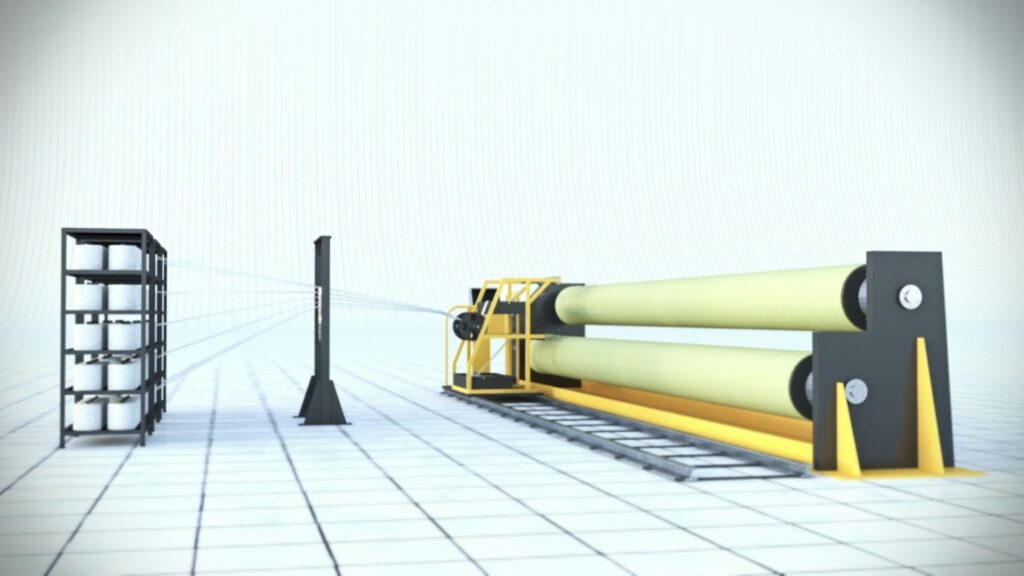

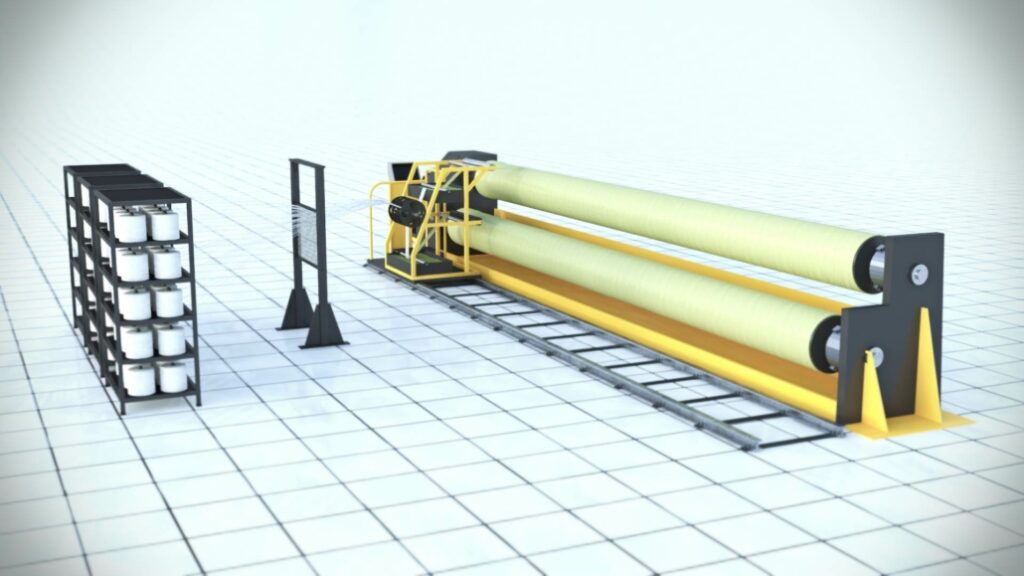

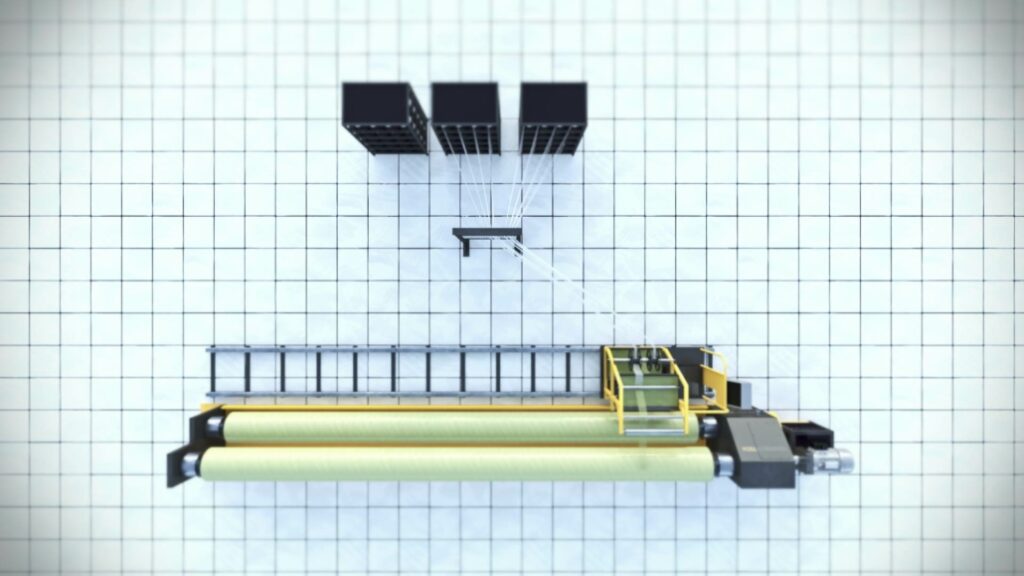

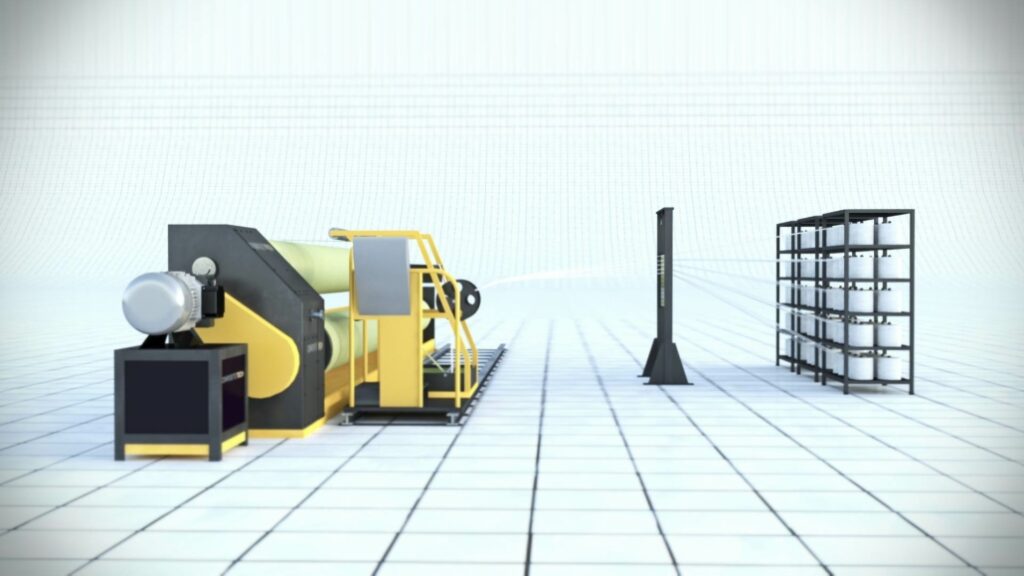

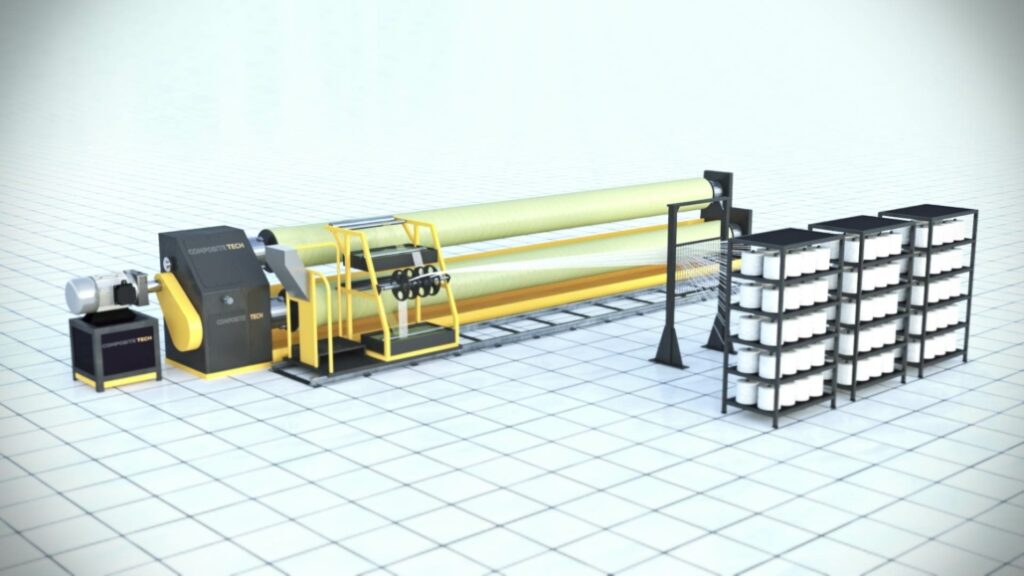

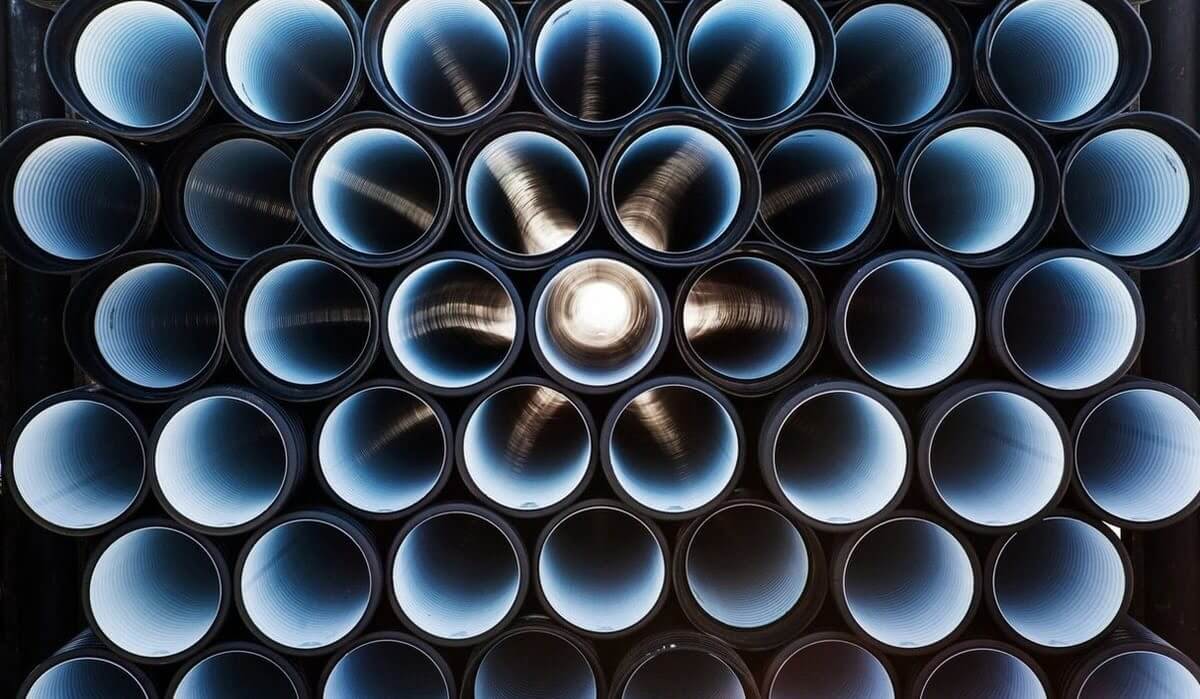

Composite-Tech est un fournisseur mondial de lignes de production de barres d'armature et de treillis en PRFV. Cette fois, nous allons encore plus loin dans l'industrie des composites en lançant notre nouvelle ligne de production de tubes en PRFV. Similaires aux barres d'armature et aux treillis en PRFV, les tubes en fibre de verre présentent de nombreux avantages par rapport aux tubes robustes conventionnels en acier, ciment, cuivre et fer, propulsant l'industrie vers un niveau supérieur de durabilité et d'efficacité.

Les lignes de production de tubes GFRP de Composite-Tech offrent :

- Automatisation complète

- Production de tubes d'un diamètre allant jusqu'à 1000 mm

- Technologie de production rentable

- Processus de production durable

Nos équipements sont conçus pour être fiables, hautement productifs et uniques dans la technologie que nous utilisons ! Tous nos développements et innovations sont brevetés, ce qui garantit non seulement une grande efficacité de votre investissement, mais aussi un marché sans concurrence. De plus, pour assurer la fiabilité de tous les modules de la ligne de production, nous utilisons uniquement des composants qui ont passé avec succès nos tests rigoureux et nos évaluations de performance.

En acquérant l'équipement de production de barres d'armature FRP Composite-Tech, nos clients bénéficient également des livrables suivants :

- Assistance dans le choix de locaux spécifiques

- Nos spécialistes réalisent l'installation des équipements et effectuent les travaux de mise en service

- Formation du personnel

- Conseils continus à vos experts techniques

Caractéristiques techniques

Caractéristiques techniques de la ligne de production de tubes en PRFV

| But: | production de tuyaux en fibre de verre |

| Diamètre des produits : | Jusqu'à 1000 mm |

| tension: | 380 V / 50 Hz |

| Pouvoir: | 30 kW |

| Performances de la ligne : | Cela dépend du diamètre |

| Longueur de l'équipement : | 12 m |

| Largeur: | 2,5 m |

| Hauteur: | 2,8 m |

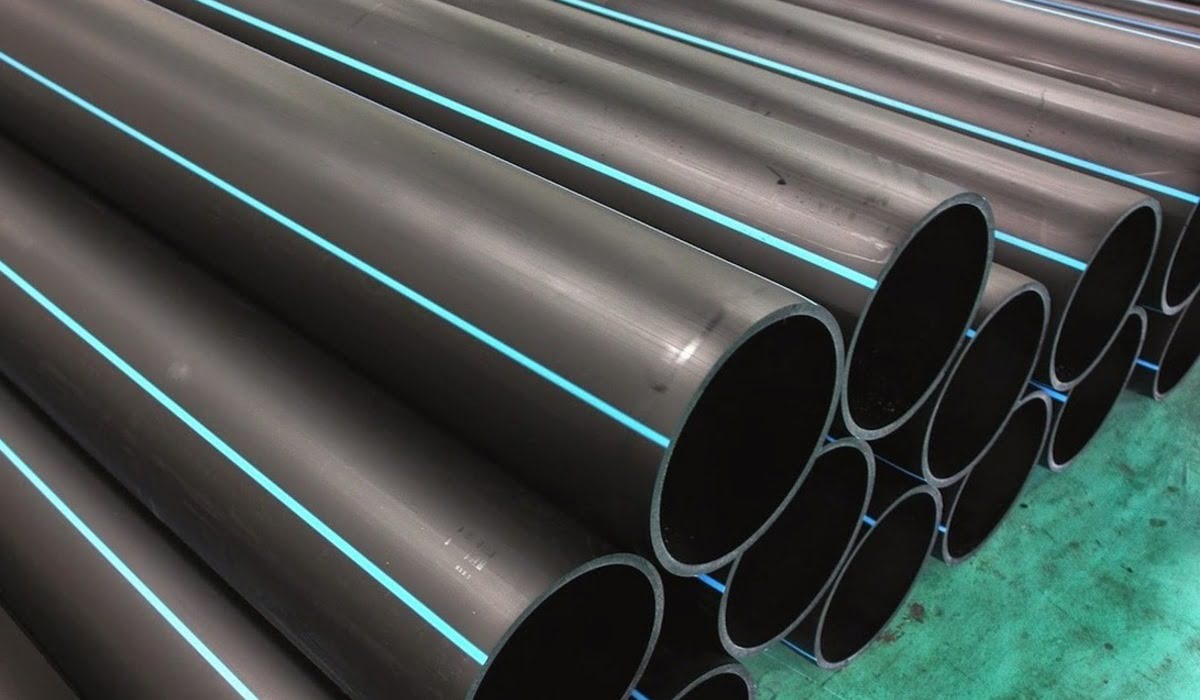

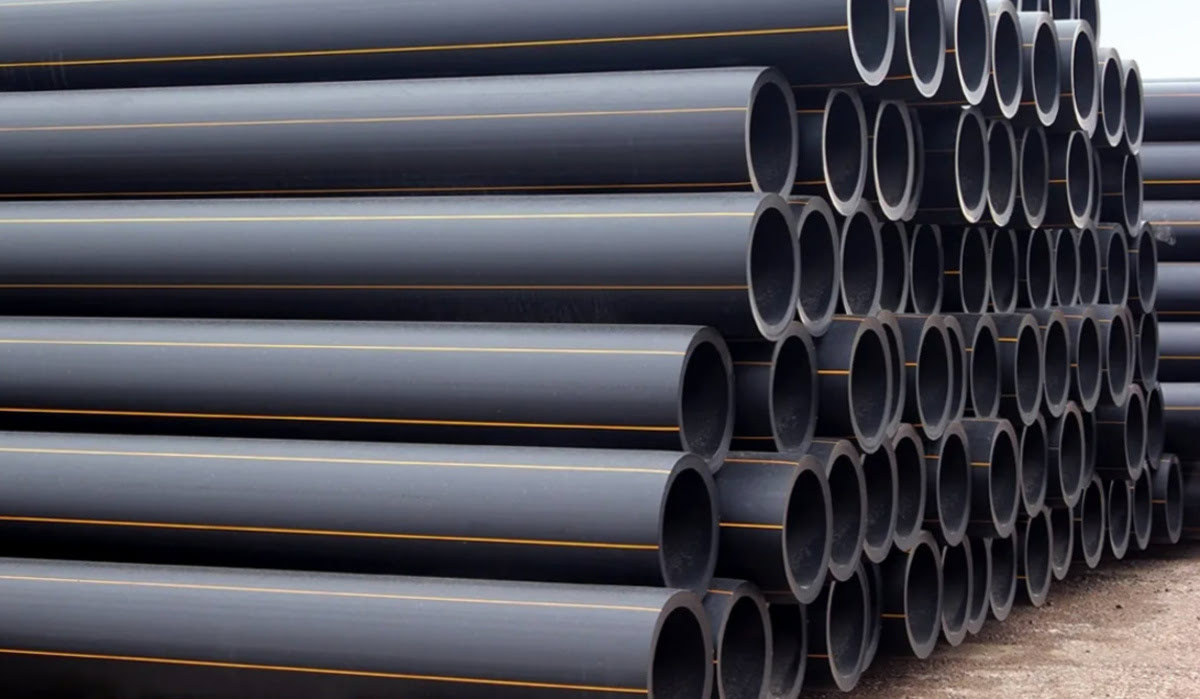

Avantages des tuyaux FRP par rapport aux tuyaux conventionnels :

- Résistance à la corrosion – Les tuyaux en PRF résistent à la corrosion résultant de l’eau de mer, des produits chimiques, du pétrole, du gaz, de la chaleur, des rayons UV et des conditions environnementales extrêmes.

- Durabilité – Le produit final de nos lignes de production de tuyaux en PRFV contribue à la durabilité de la construction, orientant l’industrie vers une solution plus respectueuse de l’environnement.

- Résistance et légèreté Les tuyaux en PRFV présentent une résistance élevée à la traction, et leur application ne nécessite ni liant, ni boulonnage, ni soudage. Ils sont plus légers que les tuyaux en fonte ductile, en acier doux et en PEHD. Leur légèreté facilite leur manipulation, leur transport et leur installation. Ces qualités rendent les tuyaux en PRFV bien plus durables, fiables et économiques que les tuyaux conventionnels.

- Résistance à la pression – La grande rigidité et la capacité de compression élevée des tuyaux en PRV empêchent leur éclatement dû aux fluctuations de pression de l'eau. Leur faible épaisseur de paroi simplifie leur mise en place et leur installation. Résistants à l'abrasion et à la fissuration, les tuyaux en PRV ne présentent aucune infiltration, nécessitent peu de traitements et ne polluent pas les eaux souterraines. Un autre avantage des tuyaux en PRV est leur capacité d'absorption de pression : ils sont conçus pour absorber les surpressions de 40%, sans augmenter la classe de pression.

- Efficacité hydraulique – Les tuyaux en PRV présentent une surface interne lisse, ce qui leur confère d'excellentes caractéristiques hydrauliques, un débit élevé et un faible frottement. Cela permet également de réduire les pertes de charge et les coûts de pompage. La température interne des tuyaux en PRV reste constante grâce à leurs propriétés thermiques uniques. Les tuyaux en PRV ordinaires ne conduisent pas l'électricité et présentent des propriétés électriques bien supérieures à celles de leurs homologues en acier. Cependant, si une conductivité électrique est requise, il est possible d'ajouter des fibres conductrices renforcées ou des charges lors de la fabrication.

Production clé en main de barres d'armature en PRV en France!

En faisant correspondre le prix de vente de vos barres d'armature en GFRP à celui des barres d'armature en acier, vous obtenez une marge bénéficiaire de plus de 1 201 TP3T !

Obtenez votre ligne de production en seulement 2 mois après avoir passé une commande et rentabilisez votre investissement en seulement 3 mois après le lancement de la production.

Application des tuyaux FRP

Les tuyaux FRP sont couramment utilisés dans les applications souterraines et aériennes, les applications sous-marines et le regarnissage pour lesquels une endurance élevée, une efficacité hydraulique et une résistance élevée sont essentielles.