La révolution du renforcement

Depuis plus d'un siècle, l'acier est l'épine dorsale des infrastructures modernes. Pourtant, les défis liés à la corrosion, au poids et à la durabilité obligent les ingénieurs à repenser l'avenir du renforcement.

Entrer GFRP (polymère renforcé de fibres de verre) — un matériau plus léger, plus résistant, non corrosif et résistant à la dégradation chimique.

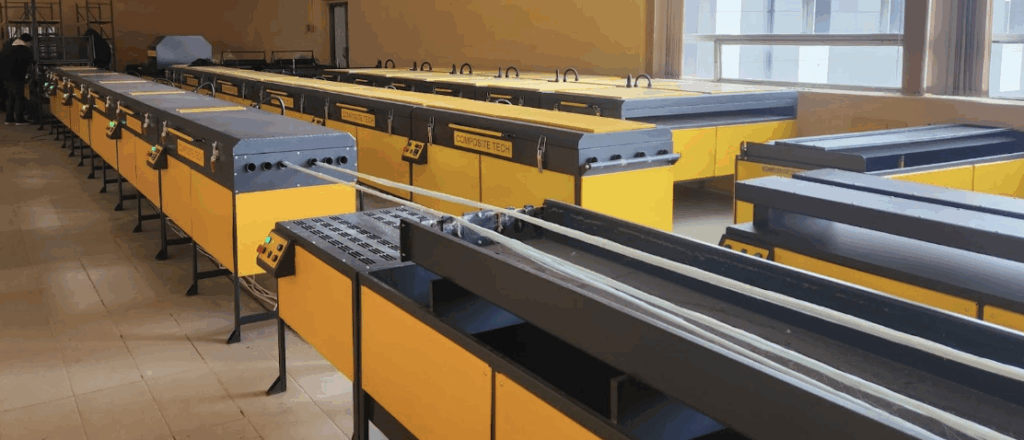

Au centre de ce changement global se trouve Composite-Tech, un fabricant européen d'équipements de pointe pour les barres d'armature, les treillis et les éléments pliés en PRF — conçus, testés et fabriqués pour répondre aux normes les plus élevées au monde.

Notre mission est simple : construire l'avenir du renforcement. Un renforcement qui dure plus longtemps, qui pèse moins et qui protège la planète.

— Anton Ocunev, PDG de Composite-Tech

De l'acier au renforcement intelligent

La corrosion à elle seule coûte plus de 100 millions de dollars à l'économie américaine. $22 milliards par an (Département des Transports des États-Unis).

Les barres d'armature en acier traditionnelles perdent jusqu'à 40% de leur résistance à la traction en 10 ans dans des environnements agressifs comme les zones côtières et les ponts.

Le PRF, en revanche :

- A un résistance à la traction 2,5 fois supérieure que l'acier

- Pèse 4x moins

- Est completely immunisé contre la corrosion

- A un durée de vie de 80 à 100 ans sans dégradation

C'est pourquoi les grands projets d'infrastructures — des ponts en Floride aux tunnels en Californie — sont désormais conçus avec Renfort en PRF en conformité avec ACI 440.11-22 et ASTM D7957.

Ingénierie de précision fabriquée en Europe

Contrairement aux équipements manuels à bas prix, Machines Composite-Tech sont conçus avec Ingénierie de précision européenne et contrôle de processus entièrement automatisé.

Chaque système assure :

- Alignement parfait des fibres

- Imprégnation uniforme de résine

- Température de durcissement constante

- Calibrage automatique du diamètre

Cette précision est ce qui garantit que chaque Barres d'armature en PRF produit sur une ligne Composite-Tech répond aux normes de performance mécanique les plus strictes requis dans le marché américain.

Recherche, tests et certification

Chaque nouvelle ligne développée par Composite-Tech passe par un cycle de tests complet :

- Essais de résistance thermique (−40°C à +200°C)

- Vérification de la résistance à la traction et à la flexion

- Analyse de l'exposition chimique et UV

La collaboration continue de Composite-Tech avec Institut FRP (États-Unis) garantit que tous les équipements et paramètres de production restent alignés avec les dernières normes ACI et ASTM, créant un processus de qualité transparent et traçable.

La durabilité comme valeur fondamentale

Au-delà de la performance, la durabilité est au cœur de la philosophie de Composite-Tech.

En permettant le remplacement de l'acier par du PRF non corrosif, l'entreprise contribue à réduire :

- émissions de CO₂ de la production d'acier

- Coûts d'entretien et de remplacement par 70%

- Déchets de béton de la détérioration des infrastructures

Le PRF n’est pas seulement une alternative : c’est une nécessité environnementale au 21e siècle.

Portée mondiale, impact local

Les machines de Composite-Tech fonctionnent désormais dans plus de 20 pays, y compris:

🇫🇷 Etats-Unis🇮🇳 Inde 🇿🇦 Afrique du Sud 🇷🇴 Roumanie 🇪🇸 Espagne 🇨🇦 Canada

Des petites startups locales aux grands fournisseurs de construction, les clients choisissent Composite-Tech parce que chaque machine est :

- Prêt pour la conformité ACI/ASTM

- Conçu pour une production continue 24h/24 et 7j/7

- Prise en charge par l'installation et la formation sur site

L'avenir : le graphène et les composites intelligents

L'équipe R&D de Composite-Tech intègre actuellement graphène nanotechnologie dans les barres d'armature en PRFV — améliorant la conductivité, la résistance et la résistance aux microfissures.

Cette nouvelle génération de renforcement va bientôt redéfinir la manière dont les ingénieurs conçoivent des structures à longue durée de vie pour les ponts, les autoroutes et les infrastructures énergétiques.

Conclusion : Ingénierie du futur

Composite-Tech combine Excellence manufacturière européenne, précision scientifique, et une vision pour la construction durable.

Chaque machine représente des décennies de recherche et une mission claire : aider les entreprises du monde entier à construire des entreprises plus solides, plus intelligentes et plus écologiques.

Prêt à construire votre propre usine FRP ?

Demandez une analyse ROI personnalisée et découvrez comment Composite-Tech peut vous aider à lancer la production dans les 60 jours.

Contact notre équipe d'ingénierie

Apprendre encore plus:

- Composite-Tech et le FRP Institute annoncent un partenariat stratégique visant à redéfinir les normes mondiales du secteur du renforcement FRP.

- Pourquoi Composite-Tech et le FRP Institute définissent les normes mondiales pour les composites

- Rentabilité de la production de barres d'armature et de treillis en PRFV aux États-Unis

- Composite-Tech : Leader mondial des équipements de production de barres d'armature, de treillis et de composites en PRFV