O Fim da Era do Aço na Infraestrutura

Por quase 100 anos, as barras de aço dominaram a construção de infraestrutura nos Estados Unidos. De pontes e rodovias a estruturas marítimas e túneis, o aço moldou a América moderna.

Mas o tempo e a ciência revelaram a fraqueza irreversível do aço: a corrosão.

Atualmente, as falhas relacionadas à corrosão custam à economia dos EUA mais de 1,6 trilhão de dólares anualmente, de acordo com a Administração Federal de Rodovias.

A exposição à água salgada, os ciclos de congelamento e descongelamento, os produtos químicos presentes no concreto e as condições ambientais atacam o aço de forma constante, enfraquecendo as estruturas por dentro.

E enquanto os Estados Unidos lançam o maior plano de gastos com infraestrutura da história moderna — mais de 1,2 trilhão de dólares sob a Lei de Investimento em Infraestrutura e Empregos — engenheiros e desenvolvedores se deparam com uma questão crucial:

Por que continuar construindo o futuro com materiais projetados para o passado?

A Ascensão do FRP — Uma Nova Era de Reforço Inteligente

O que é vergalhão de FRP?

A armadura de FRP (Polímero Reforçado com Fibra) — principalmente GFRP (Polímero Reforçado com Fibra de Vidro) — é um reforço composto de alta resistência e à prova de corrosão, projetado para substituir o aço em estruturas de concreto.

Principais vantagens de desempenho

| Propriedade | Aço | Vergalhões de PRFV |

| Resistência à corrosão | Corrói | 100% à prova de corrosão |

| Resistência à tracção | ~60 ksi | 120–200 ksi (2–3 vezes mais forte) |

| Peso | Pesado | 4 vezes mais leve |

| Condutividade térmica | Condutor | Não condutor (seguro contra radiação eletromagnética) |

| Interferência magnética | Sim | Nenhum — seguro para ressonância magnética e radar. |

| Vida útil | 20 a 50 anos | Até 100+ anos |

Resultado: Menos manutenção, maior vida útil, estruturas mais seguras, menor custo total ao longo da vida útil.

Por que os Estados Unidos precisam de FRP agora?

Infraestrutura Costeira e Marinha

Da Flórida à Califórnia, a exposição ao sal destrói o concreto armado com aço.

A fibra de vidro reforçada com plástico (FRP) não enferruja — nunca.

- Pontes costeiras

- Quebra-mares e portos

- Estações de tratamento de águas residuais

- Instalações de dessalinização

Transportes e Pontes

O Departamento de Transportes dos EUA relata Mais de 42.000 pontes com deficiências estruturais.

O PRFV (Plástico Reforçado com Fibra de Vidro) prolonga a vida útil e reduz os custos de reabilitação.

Estruturas Militares e de Defesa Crítica

FRP é não condutor e não magnético — essencial para sistemas de radar, centros de dados e instalações de defesa.

Infraestrutura de energia limpa e veículos elétricos

Usinas de baterias de nova geração, instalações de hidrogênio e centros de energia exigem reforço não corrosivo e não condutor.

Conformidade com as normas de engenharia dos EUA

As barras de reforço de GFRP modernas estão em conformidade com as principais normas dos EUA:

| Padrão | Descrição |

| ACI 440.11-22 | Código de projeto de vergalhões de PRFV |

| ASTM D7957 | Especificação padrão para PRFV (Plástico Reforçado com Fibra de Vidro) |

| Aprovação do FDOT | Para construção na Flórida |

| CSA S806 | Código de projeto norte-americano |

Equipamento Composite-Tech é projetado para fabricar Produtos de FRP que atendem — e superam — essas especificações.

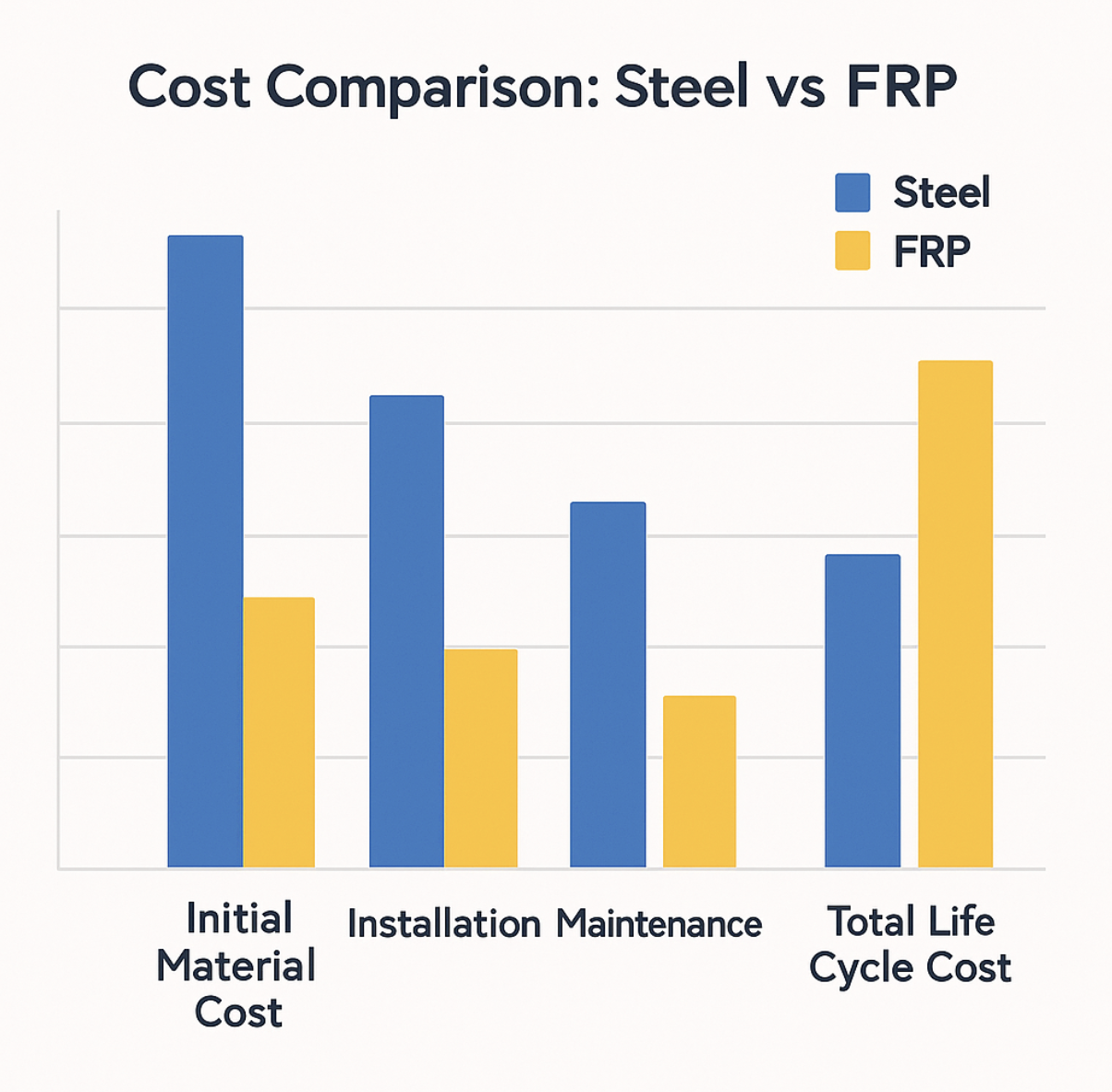

Análise de custos: aço versus PRFV (Plástico Reforçado com Fibra de Vidro)

Conversa tradicional:

“O aço é mais barato por tonelada.”

Realidade moderna:

Custo total ao longo da vida útil > Custo de aquisição.

| Categoria de custo | Aço | PRFV |

| Custo inicial do material | Mais baixo | Um pouco mais alto |

| Instalação | Requer equipamento pesado | Leveza = maior velocidade e menor custo |

| Manutenção | Alto (reparo de corrosão) | Próximo de zero |

| Vida útil | 20 a 50 anos | 80–100+ anos |

| Custo total do ciclo de vida | Alto | Mais baixo |

Conclusão: O FRP se destaca na análise econômica do ciclo de vida — a métrica mais importante para projetos governamentais e grandes desenvolvedores de infraestrutura.

Por que os fabricantes escolhem a Composite-Tech?

A adoção moderna de PRFV (Plástico Reforçado com Fibra de Vidro) nos Estados Unidos não é apenas impulsionada pela demanda — é impulsionado pela tecnologia.

Os equipamentos da Composite-Tech garantem:

- Qualidade em conformidade com ACI/ASTM

- Fabricação automatizada (operação 24 horas por dia, 7 dias por semana)

- Alinhamento preciso da fibra

- Impregnação consistente de resina

- Controle perfeito de cura

- Calibração de diâmetro estável

E o mais importante?

Os parâmetros de produção garantidos foram testados para atender aos padrões dos EUA.

Histórias de sucesso no mundo real

Flórida, EUA — Fábrica de PRFV Costeira

- região de exposição extrema ao sal

- FRP (plástico reforçado com fibra de vidro) é escolhido para substituir o aço na infraestrutura marítima.

- As linhas de produção da Composite-Tech produzem vergalhões de alto volume 24 horas por dia, 7 dias por semana

Índia — Expansão em larga escala de PRFV (Plástico Reforçado com Fibra de Vidro)

- Governo pressiona por infraestrutura resistente à corrosão

- Os sistemas Composite-Tech foram escolhidos pela sua escalabilidade e precisão.

- Atende rodovias, túneis de metrô e projetos industriais.

Engenheiros escolha-nos Não apenas para desempenho, mas também para parcerias, treinamento e suporte a padrões.

Olhando para o futuro — PRFV reforçado com grafeno

A Composite-Tech está aprimorando o GFRP para a próxima geração:

Barra de reforço composta reforçada com grafeno.

Benefícios:

- Aumento da resistência à tração

- Capacidade de preencher fissuras

- Maior durabilidade

- Aplicações emergentes de controle de condutividade

Essa inovação posiciona o FRP como o tecnologia de reforço definitiva para o próximo século da infraestrutura americana.

Conclusão

O aço serviu o mundo durante um século. O PRFV (Plástico Reforçado com Fibra de Vidro) impulsionará o próximo.

Os Estados Unidos estão entrando em uma nova era de infraestrutura — mais inteligente, mais durável e ambientalmente responsável.

O FRP não é apenas um material melhor — é o novo padrão.

Pronto para começar a fabricar vergalhões de PRFV nos Estados Unidos?

A Composite-Tech fornece soluções de produção completas, Suporte para instalação, treinamento e certificação.

Solicite o seu plano de retorno do investimento (ROI) para fábrica de PRFV (Plástico Reforçado com Fibra de Vidro).

Agende uma consulta técnica.

Saber mais:

- Como instalar vergalhões de fibra de vidro (GFRP) em lajes de concreto

- Da Flórida à Índia: como as máquinas de tecnologia de compósitos capacitam os líderes globais em PRFV (Plástico Reforçado com Fibra de Vidro).

- Por que a Composite-Tech e o FRP Institute estão definindo os padrões globais para compósitos?

- ACI 440.11-22 Explicado: Como Projetar Concreto com Vergalhões de PRFV nos EUA

- Entendendo a norma ACI 440.11-22 para fabricantes de vergalhões de GFRP

- Grafeno na produção de vergalhões de GFRP: uma revolução no reforço de concreto

- Vergalhão de fibra de vidro #3 (3/8 pol.): preço, peso e casos de uso reais nos EUA

- Por que a Composite-Tech é líder global em equipamentos de produção de GFRP

- Vergalhões de PRFV vs. Aço: Custo, Resistência e Benefícios a Longo Prazo na Construção Moderna

- Vergalhões de PRFV vs. vergalhões de aço: uma comparação técnica completa

- Can Fiberglass Rebar Replace Steel in Foundations and Driveways?