Vergalhões de PRFV vs. Aço: Custo, Resistência e Benefícios a Longo Prazo na Construção Moderna

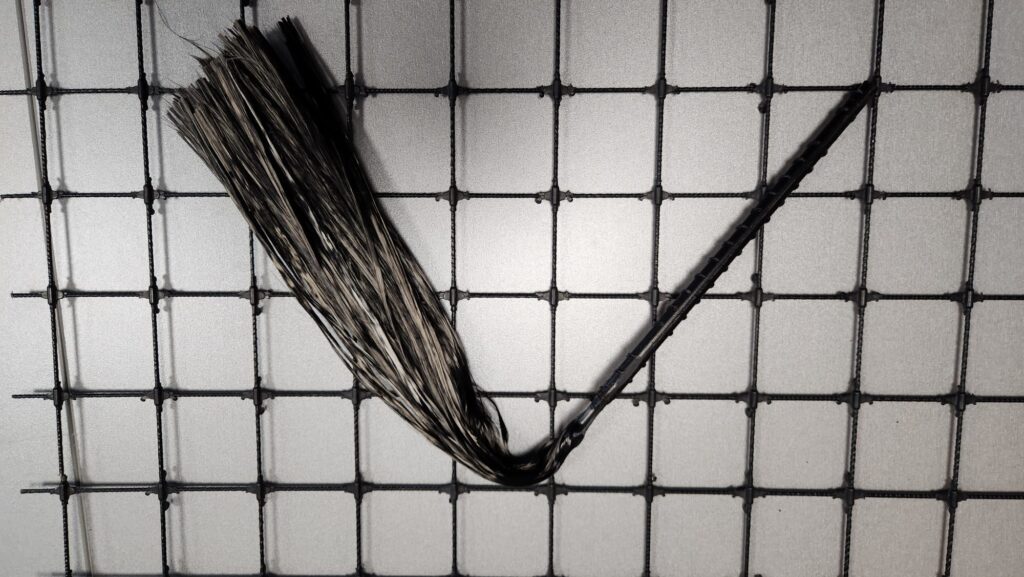

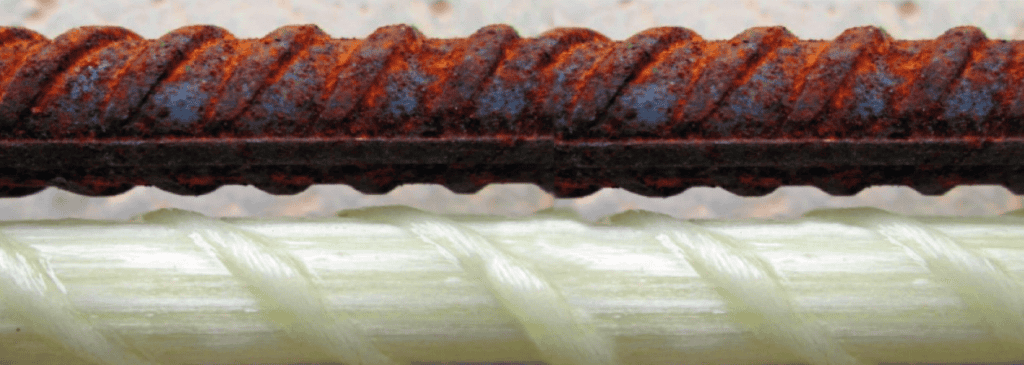

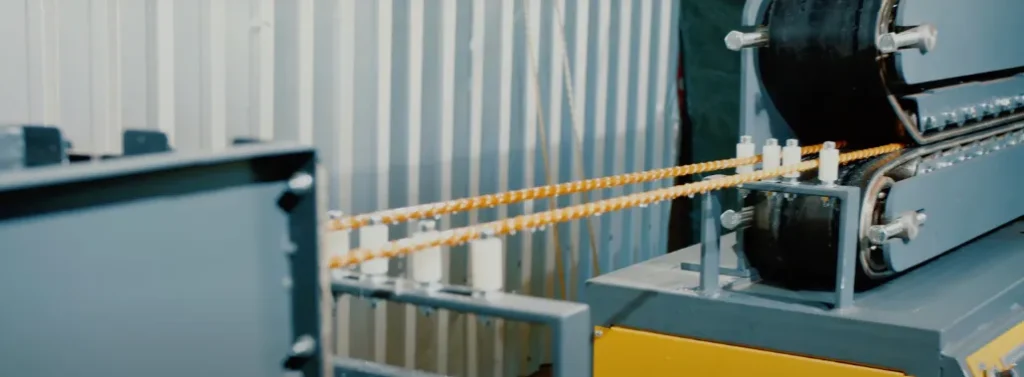

No setor da construção civil, em rápida evolução, as barras de reforço de polímero reforçado com fibra de vidro (GFRP) estão surgindo como uma alternativa revolucionária ao reforço de aço tradicional. Embora o aço tenha […]