Composite-Tech przenosi przemysł kompozytów dalej niż kiedykolwiek wcześniej, wprowadzając naszą nowo opracowaną linię produkcyjną zbiorników FRP. Zbiorniki kompozytowe wykonane z włókna szklanego mają mnóstwo zalet w porównaniu z konwencjonalnymi zbiornikami z tworzywa sztucznego i żelaza o dużej wytrzymałości, podnosząc przemysł na nowy poziom zrównoważonego rozwoju i skuteczności.

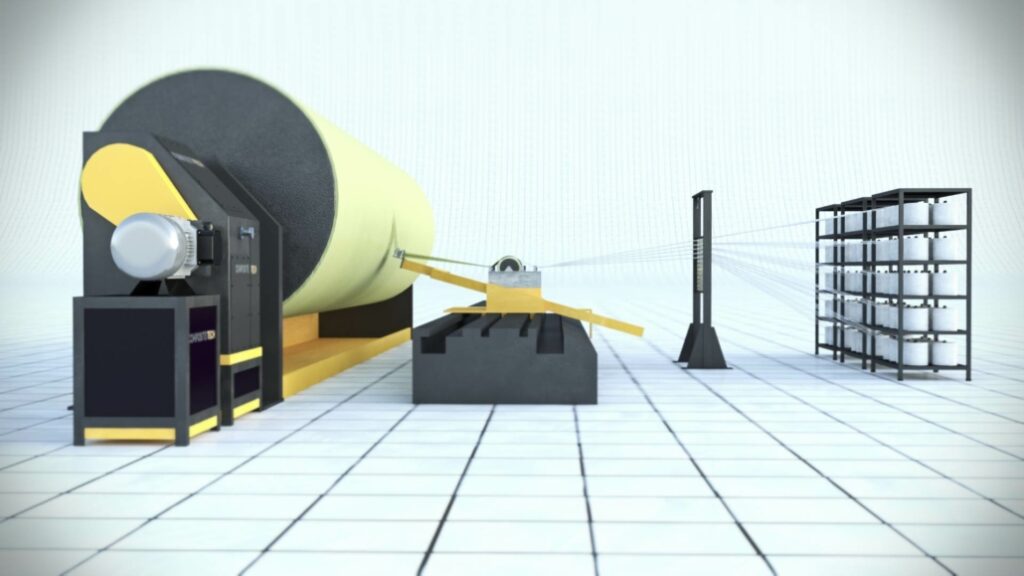

Linie produkcyjne zbiorników GFRP Composite-Tech oferują:

- Pełna automatyzacja

- Szeroka gama typów zbiorników i zastosowań (patrz poniżej)

- Ekonomiczna technologia produkcji

- Zrównoważony proces produkcji

Zbiorniki kompozytowe FRP typu Composite-Tech są stosowane w:

- Przemysł naftowy i gazowy

- Przemysł rolniczy (przechowywanie nasion i nie tylko)

- Magazynowanie wody

- Przechowywanie chemikaliów

- Magazynowanie LPG/LNG

- Przechowywanie paliwa

Nasz sprzęt jest zaprojektowany tak, aby był niezawodny, wysoce produktywny i wyjątkowy w technologii, którą wykorzystujemy! Wszystkie nasze rozwiązania i innowacje są opatentowane, co gwarantuje nie tylko wysoką efektywność inwestycji, ale także wolny rynek konkurencji. Ponadto, aby zapewnić niezawodność wszystkich modułów linii produkcyjnej, używamy tylko tych komponentów, które przeszły nasze rygorystyczne testy i oceny wydajności.

Dzięki nabyciu sprzętu do produkcji zbiorników GFRP Composite-Tech nasi klienci w Polsce uzyskali również następujące produkty:

- Pomoc w wyborze pomieszczeń specjalistycznych

- Nasi specjaliści wykonują montaż urządzeń i prace uruchomieniowe

- Szkolenie personelu

- Ciągłe doradztwo naszych ekspertów technicznych

Dane techniczne

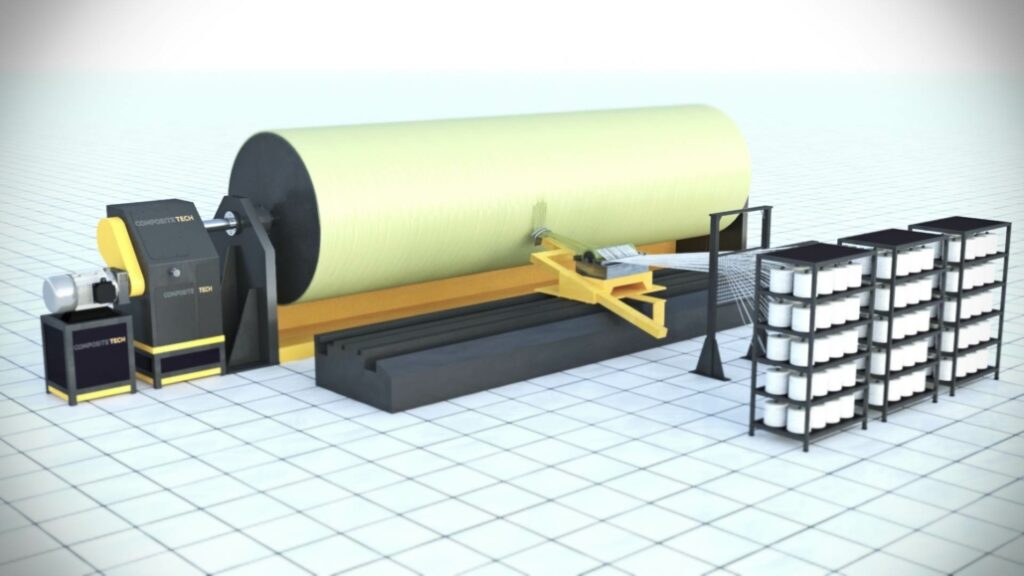

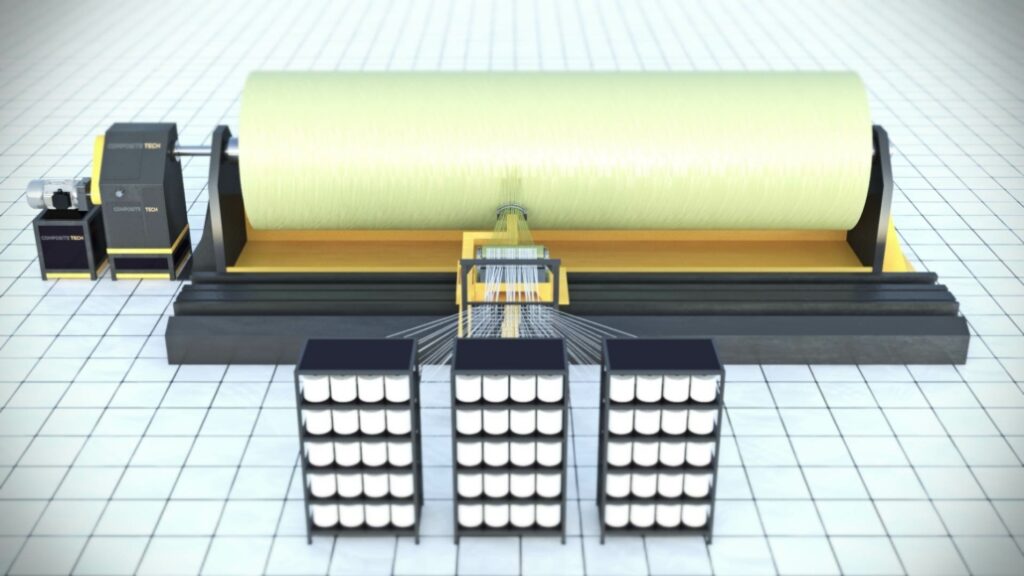

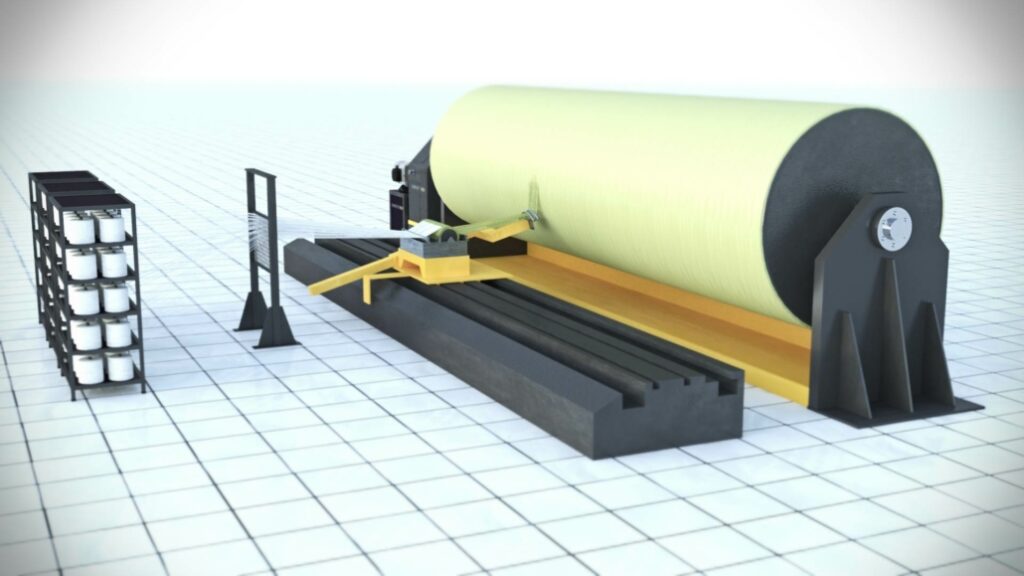

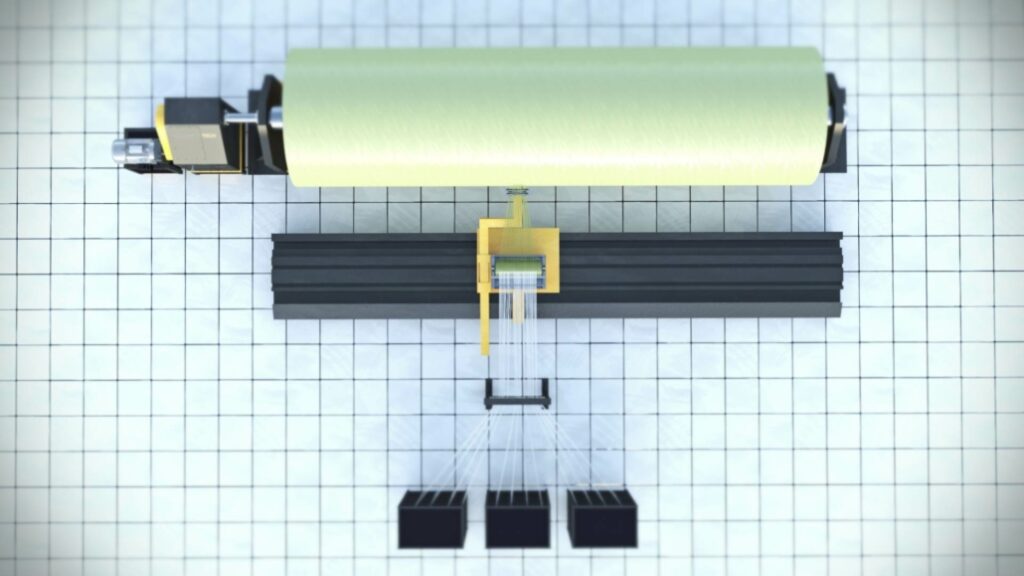

Charakterystyka techniczna linii produkcyjnej zbiorników GFRP

| Zamiar: | produkcja zbiorników z włókna szklanego |

| Woltaż: | 380 V / 50 Hz |

| Moc: | 30 kW |

| Wydajność linii: | Zależy od produktu końcowego |

| Długość sprzętu: | 12 minut |

| Szerokość: | 2,5m |

| Wysokość: | 2,8m |

Zalety zbiorników FRP w porównaniu ze zbiornikami stosowanymi konwencjonalnie:

- Odporność na korozję – Zbiorniki FRP są odporne na korozję powodowaną przez wodę morską, chemikalia, olej, gaz, ciepło, promienie UV i ekstremalne warunki środowiskowe.

- Zrównoważony rozwój – Produkt końcowy naszych linii produkcyjnych zbiorników kompozytowych przyczynia się do zrównoważonego rozwoju w budownictwie, skłaniając branżę do stosowania bardziej przyjaznych dla środowiska rozwiązań.

- Siła / Lekkość – Wysoka wytrzymałość sprawia, że zbiorniki z włókna szklanego są odporne na wibracje i inne siły wewnętrzne i zewnętrzne oddziałujące na zbiornik. Zbiorniki z włókna szklanego są lekkie w porównaniu do zbiorników z żeliwa sferoidalnego, miękkiej stali i HDPE. Niska waga zapewnia łatwą obsługę, transport i instalację. Te cechy sprawiają, że zbiorniki FRP są o wiele trwalsze, bardziej niezawodne i ekonomiczne niż zbiorniki konwencjonalne.

- Odporność na stany zapalne – W przeciwieństwie do swoich żeliwnych odpowiedników, zbiorniki FRP nie wybuchają, nie zajmują się ogniem ani nie podtrzymują go.

- Opcje dostosowywania – Przystosowane do praktycznie wszystkich możliwych wymagań przemysłowych.

- Brak skażenia – Zbiorniki z tworzywa GFRP nie rdzewieją, dlatego nie mają żadnego wpływu na przechowywane płyny, bez względu na to, czy jest to woda, gaz płynny czy chemikalia.

- Minimalna konserwacja i naprawa – Długa żywotność eliminuje dodatkowe koszty związane z naprawami.

- Odporność na ciśnienie – Wysoka sztywność i wysoka nośność ściskająca zbiorników FRP zapobiegają wahaniom ciśnienia pękania. Mają mniejszą grubość ścianek, co upraszcza umieszczanie i instalację takich zbiorników. Zbiorniki Fibergalss są odporne na ścieranie i pękanie, charakteryzują się zerową infiltracją, niskimi wymaganiami obróbki i brakiem zanieczyszczenia wód gruntowych. Dodatkową zaletą zbiorników kompozytowych jest absorpcja ciśnienia: są zaprojektowane tak, aby absorbować 40% ciśnienia udarowego, bez zwiększania klasy ciśnienia.

- Sprawność hydrauliczna – Zbiorniki GRP mają gładką powierzchnię wewnętrzną, co wspomaga doskonałe właściwości hydrauliczne, wysoką przepustowość i niskie tarcie. To również oznacza niskie straty ciśnienia i koszty pompowania. Temperatura wewnętrzna zbiorników GRP pozostaje stała ze względu na ich unikalne właściwości termiczne. Zwykłe zbiorniki GRP nie przewodzą prądu i mają znacznie lepsze właściwości elektryczne niż ich stalowe odpowiedniki.

Produkcja prętów zbrojeniowych GFRP pod klucz w Polsce!

Dopasowując cenę sprzedaży prętów zbrojeniowych GFRP do ceny prętów stalowych, osiągasz marżę zysku przekraczającą 120%!

Zamów linię produkcyjną już w 2 miesiące od złożenia zamówienia, a inwestycja zwróci się już po 3 miesiącach od uruchomienia produkcji.

Zastosowanie zbiornika FRP:

Zbiorniki FRP są powszechnie używane w zastosowaniach podziemnych i naziemnych, w zastosowaniach podwodnych i jako wykładziny, w przypadku których wysoka wytrzymałość, wydajność hydrauliczna i duża wytrzymałość są niezbędne.