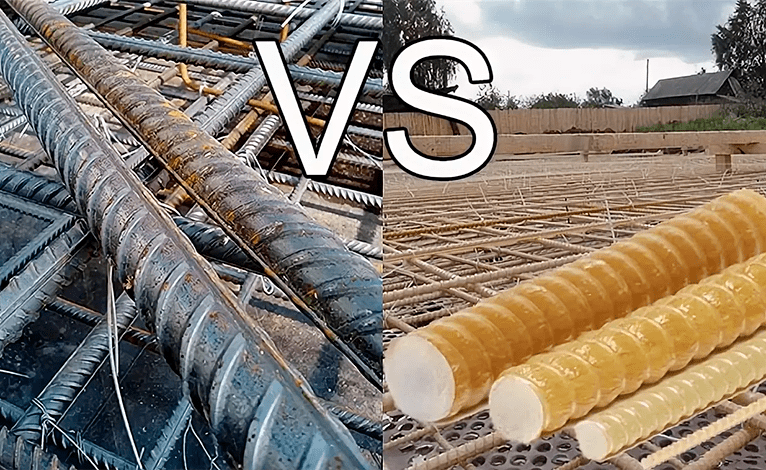

W nowoczesnym inżynierii lądowej i rozwoju infrastruktury wybór materiału wzmacniającego ma ogromny wpływ na trwałość, koszt i ogólną wydajność konstrukcji betonowych. Tradycyjnie dominującym wyborem były stalowe pręty zbrojeniowe ze względu na ich wytrzymałość i dostępność. Jednak pręty zbrojeniowe z polimeru wzmacnianego włóknem szklanym (GFRP) zyskały znaczną uwagę w ostatnich latach jako lepsza alternatywa dla konkretnych zastosowań. W tym artykule przedstawiono kompleksowe, oparte na danych porównanie prętów zbrojeniowych GFRP i stalowych, biorąc pod uwagę właściwości mechaniczne, trwałość, wagę, wpływ ekonomiczny i przykłady specyficzne dla projektu.

Porównanie właściwości mechanicznych

Wytrzymałość mechaniczna jest głównym czynnikiem przy wyborze wzmocnienia. Poniżej znajduje się tabela porównawcza kluczowych cech mechanicznych:

| Nieruchomość | Pręty zbrojeniowe stalowe (A615 Gr.60) | Pręty zbrojeniowe GFRP |

| Wytrzymałość na rozciąganie | ~550 MPa | 1000–1500 MPa |

| Moduł sprężystości | ~200 GPa | 60–80 GPa |

| Wytrzymałość na rozciąganie | ~500 MPa | Nie dotyczy (kruche) |

| Gęstość | ~7850 kg/m³ | ~1900 kg/m³ |

Interpretacja:

- GFRP ma 2–3 razy większą wytrzymałość na rozciąganie.

- Moduł sprężystości GFRP jest około 4–5 razy niższy, co powoduje większe ugięcie pod obciążeniem, co ma kluczowe znaczenie przy projektowaniu.

Przypadek użycia:

W przypadku mostów o dużej rozpiętości lub barier drogowych GFRP wytrzymuje większe obciążenia rozciągające, ale wymaga odpowiedniej konstrukcji przekroju ze względu na niższą sztywność.

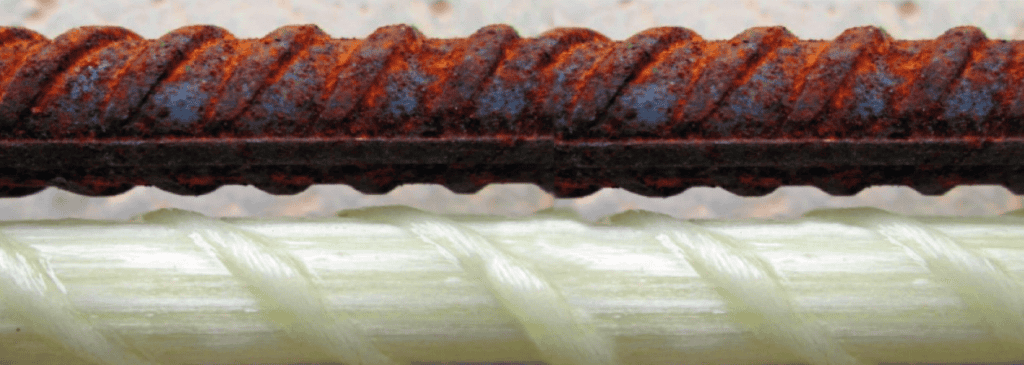

Odporność na korozję i żywotność

Jedną z największych wad stali jest jej podatność na korozję, zwłaszcza w środowiskach o dużej zawartości chlorków, takich jak konstrukcje morskie i obszary odladzania.

| Parametr | Stal | GFRP |

| Odporność na korozję | Słaby | Doskonały (niekorozyjny) |

| Żywotność w trudnych warunkach | 20–30 lat | 80–100+ lat |

Studium przypadku: Marina del Rey Seawall, Kalifornia

- Oryginalne zbrojenie stalowe skorodowało w ciągu 25 lat.

- Wymieniono na pręty zbrojeniowe GFRP, które mają wytrzymać ponad 100 lat bez korozji.

Wniosek: GFRP jest zdecydowanym zwycięzcą w przypadku konstrukcji narażonych na działanie soli, wilgoci, chemikaliów lub skrajnej wilgotności.

Waga i wydajność obsługi

GFRP jest znacznie lżejszy od stali, co ma bezpośredni wpływ na koszty wysyłki, czas realizacji i złożoność instalacji.

| Nieruchomość | Pręty zbrojeniowe | Pręty zbrojeniowe GFRP |

| Waga względna | 100% | ~25% (1/4 stali) |

| Obsługa ręczna | Wymaga maszyn | Praca jednoosobowa |

| Koszt transportu | Wysoki | Do 50% niżej |

Przykład: W regionach górzystych, takich jak Nepal czy państwa wyspiarskie, firmy budowlane informują o oszczędnościach logistycznych przekraczających 30% dzięki wykorzystaniu GFRP.

Właściwości elektromagnetyczne i termiczne

GFRP jest materiałem nieprzewodzącym i stabilnym termicznie.

| Charakterystyczny | Stal | GFRP |

| Przewodność elektryczna | Wysoki | Nic |

| Przewodność cieplna | Wysoki | Bardzo niski |

| Zakłócenia pola magnetycznego | Tak | Nic |

Zastosowania:

- Pomieszczenia MRI w szpitalach

- Podstacje i elektrownie

- Tunele kolejowe

W takich środowiskach GFRP gwarantuje bezpieczeństwo i integralność funkcjonalną.

Porównanie kosztów i ekonomia cyklu życia

Mimo że początkowy koszt GFRP jest zazwyczaj 1,5–2 razy wyższy od kosztu stali, w wielu przypadkach całkowity koszt cyklu życia (LCC) jest niższy.

| Faza | Pręty zbrojeniowe | Pręty zbrojeniowe GFRP |

| Koszt materiału (początkowy) | $0,75/kg | $1,5–2,0/kg |

| Koszt instalacji | Wyższy | Niżej |

| Koszty utrzymania | Bardzo wysoki | Minimalny |

| Całkowity LCC (50 lat) | 100% | ~65–75% |

Przykład: Most betonowy o długości 1 km na Florydzie wymagał $1.2M naprawy antykorozyjnej po 20 latach. Podobny most zbudowany z GFRP nie wykazał degradacji po 25 latach.

Ograniczenia projektowe GFRP

Pomimo zalet, GFRP ma pewne ograniczenia konstrukcyjne:

- Tryb kruchego uszkodzenia:Brak osiągnięcia pułapu wydajności, zatem współczynniki bezpieczeństwa muszą zostać dostosowane.

- Niski moduł: Zwiększone ugięcie, jeżeli nie zostanie skompensowane przez geometrię.

- Brak gięcia na miejscu:Musi być prefabrykowany zgodnie ze specyfikacją.

Rozwiązania:

- Należy stosować wygięte strzemiona i siatkę z włókna szklanego wzmacnianego włóknem szklanym.

- Zastosuj normy projektowania kompozytów (ACI 440.1R) w celu zapewnienia bezpiecznego planowania konstrukcji.

Normy i zgodność

GFRP jest uznawany przez wiodące międzynarodowe kodeksy:

- ACI 440.1R (Stany Zjednoczone) – Wytyczne projektowe dla zbrojenia FRP

- CSA S807 / S806 (Kanada) – Beton zbrojony z FRP

- CNR-DT 203 (Włochy) – Europejskie wytyczne

Normy te określają jasne zasady bezpiecznego stosowania i promują ich przyjęcie na całym świecie.

Ostateczny wniosek

Pręty zbrojeniowe GFRP nie są uniwersalnym zamiennikiem stali, ale w środowiskach korozyjnych, odległych lub wrażliwych na pole elektromagnetyczne zapewniają dłuższą żywotność, niższe koszty cyklu życia i łatwiejszą obsługę.

Biorąc pod uwagę rosnące zapotrzebowanie na infrastrukturę i coraz większą odporność na zmiany klimatu, GFRP stanowi przyszłościową inwestycję w przypadku wielu rodzajów budownictwa.

Composite-Tech zapewnia najnowocześniejszy sprzęt do zautomatyzowanej produkcji Pręty zbrojeniowe GFRP I oczko, pomagając firmom budowlanym na całym świecie w przejściu na inteligentniejsze, mocniejsze i bardziej zrównoważone rozwiązania w zakresie zbrojenia.