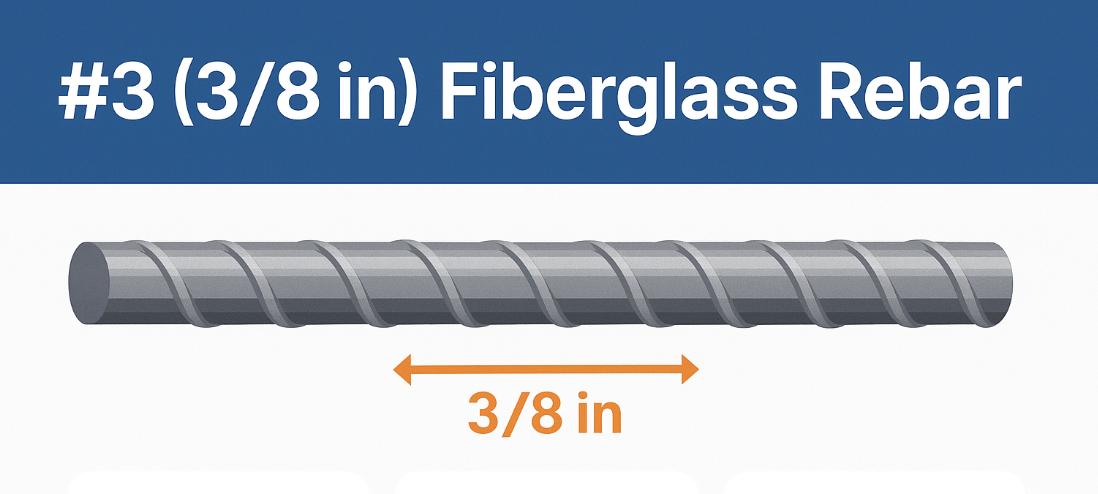

#3 (3/8 инча) фибростъклена арматура: Реални цени, тегло и случаи на употреба в САЩ

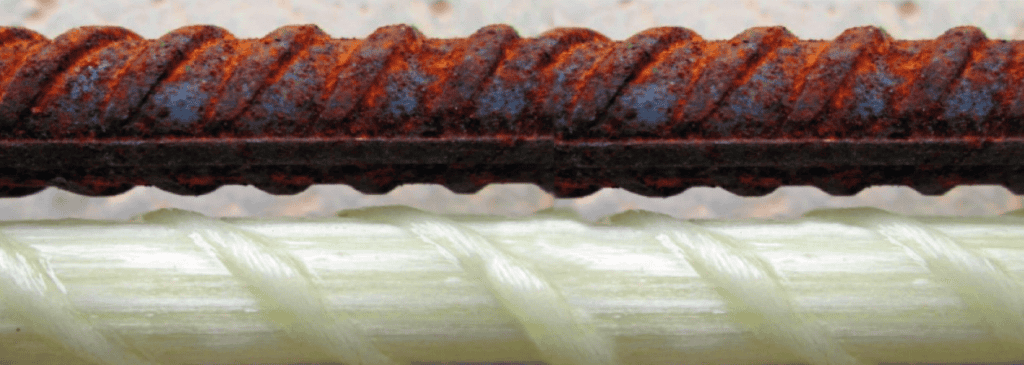

В Съединените щати, армировката от фибростъкло #3 (3/8 инча) бързо се превърна в един от най-търсените размери армировка от полимер, подсилен със стъклени влакна (GFRP).