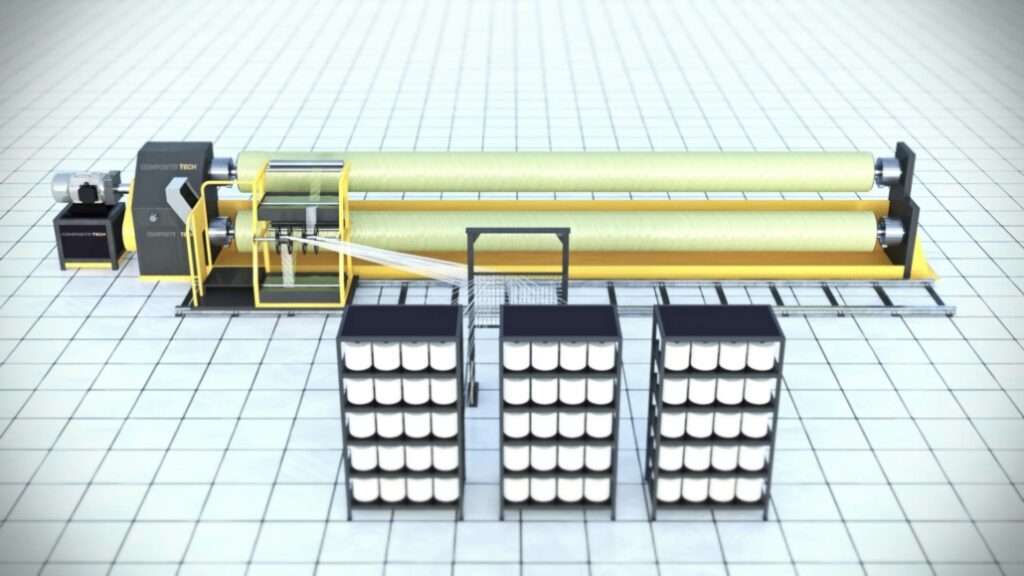

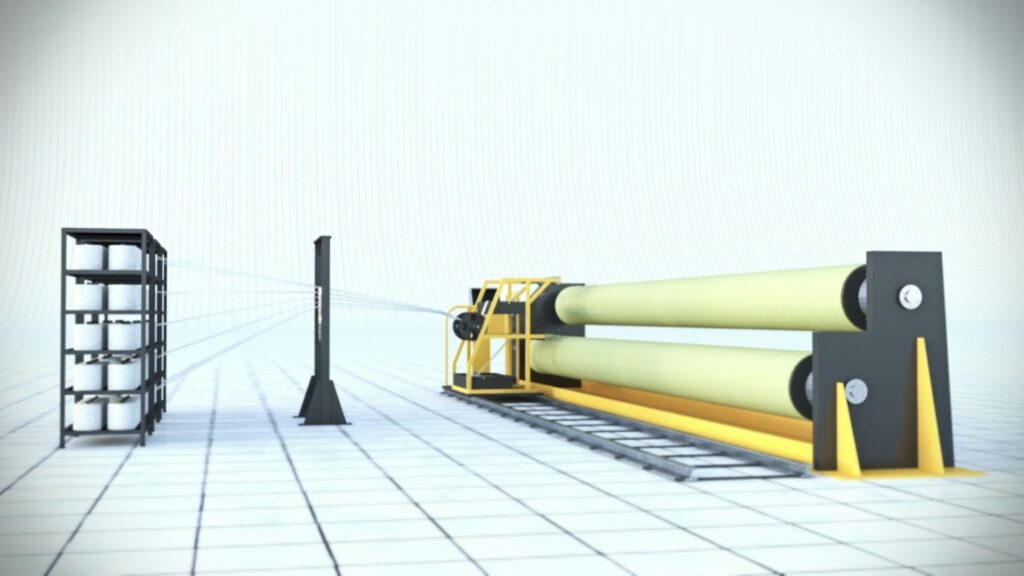

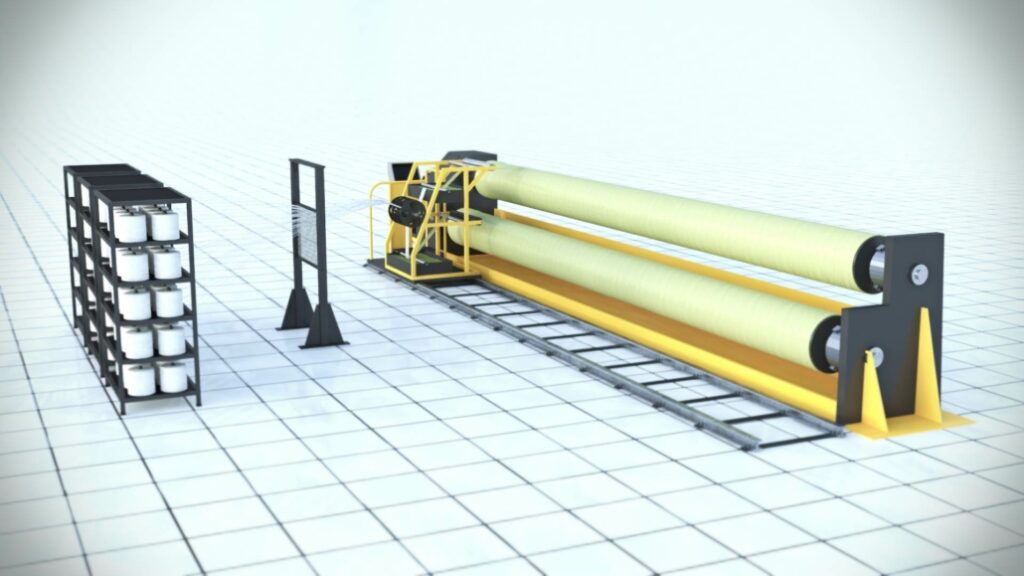

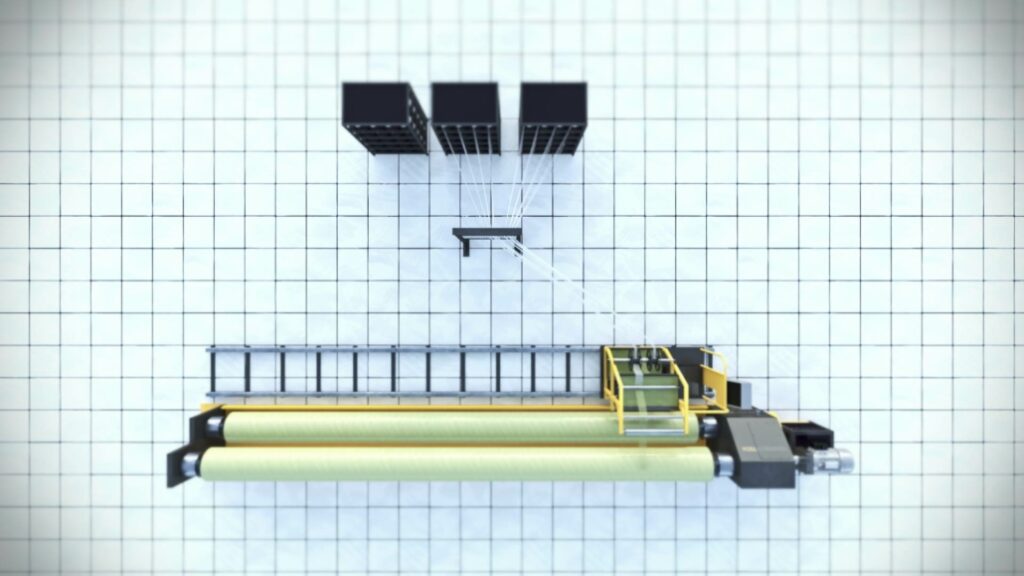

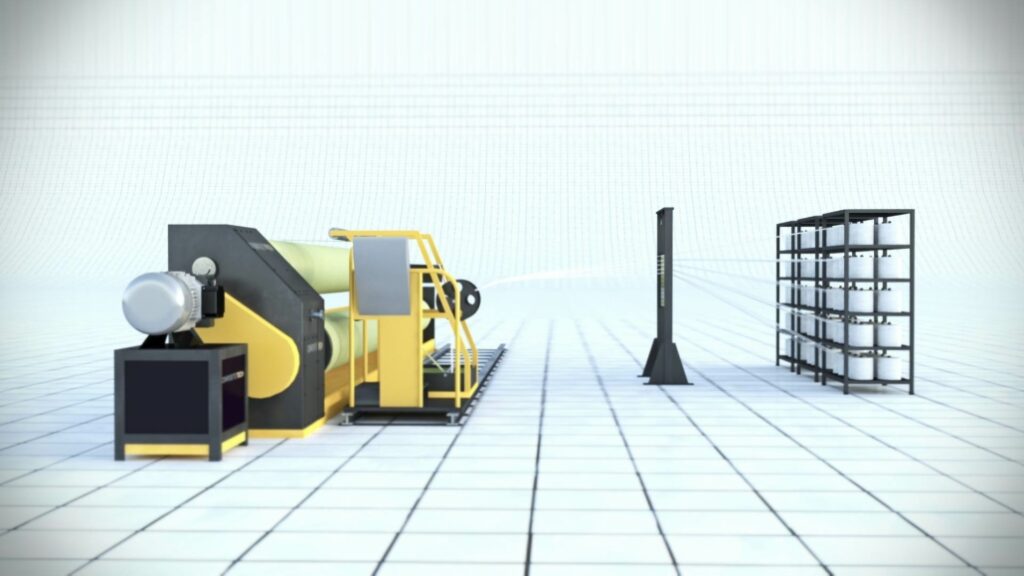

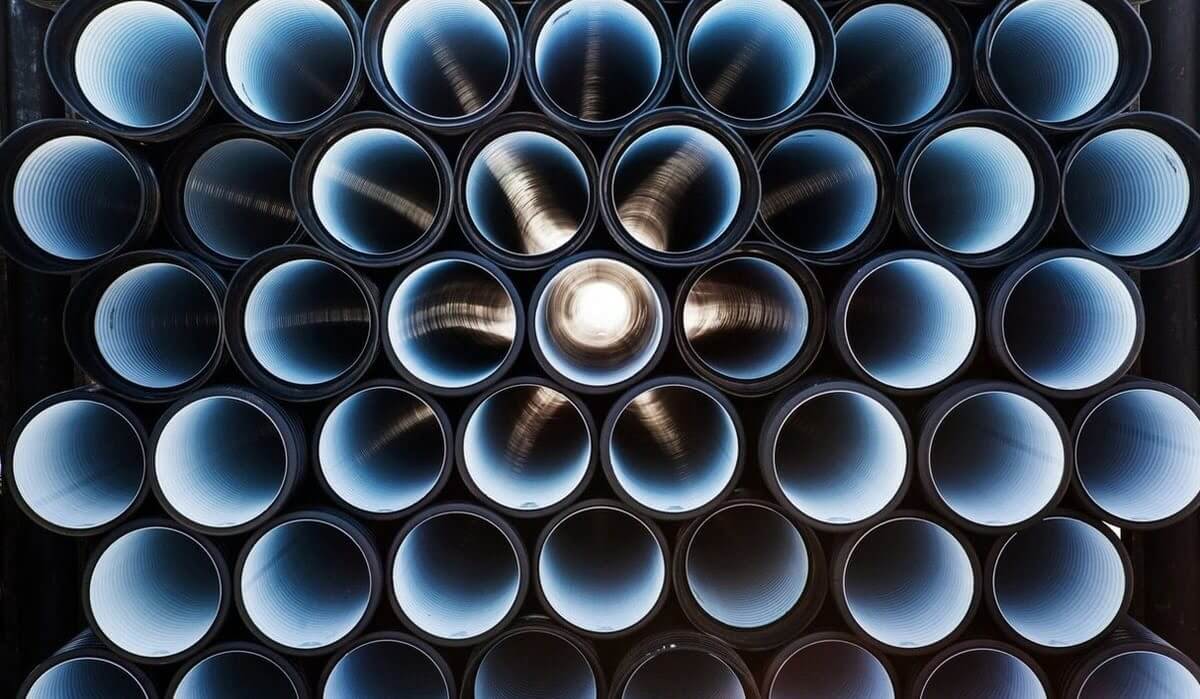

Composite-Tech — это глобальный поставщик линий по производству арматуры и сетки из стеклопластика. На этот раз мы выводим отрасль композитных материалов еще дальше, представляя нашу недавно разработанную линию по производству труб из стеклопластика. Подобно арматуре и сетке из стеклопластика, трубы из стекловолокна обладают множеством преимуществ по сравнению с обычными стальными, цементными, медными и железными трубами большой грузоподъемности, выводя отрасль на новый уровень устойчивости и эффективности.

Линии по производству стеклопластиковых труб Composite-Tech предлагают:

- Полная автоматизация

- Производство труб диаметром до 1000мм

- Экономически эффективная технология производства

- Устойчивый производственный процесс

Наше оборудование спроектировано так, чтобы быть надежным, высокопроизводительным и уникальным по используемой технологии! Все наши разработки и инновации запатентованы, что гарантирует не только высокую эффективность ваших инвестиций, но и свободу конкуренции на рынке. Более того, для обеспечения надежности всех модулей производственной линии мы используем только те компоненты, которые прошли наши строгие испытания и оценки производительности.

Приобретая оборудование Composite-Tech для производства стеклопластиковой арматуры, наши клиенты также получают следующие результаты:

- Помощь в подборе специального помещения

- Наши специалисты осуществляют монтаж оборудования и выполняют пуско-наладочные работы.

- Обучение персонала

- Постоянные консультации вашим техническим специалистам

Технические характеристики

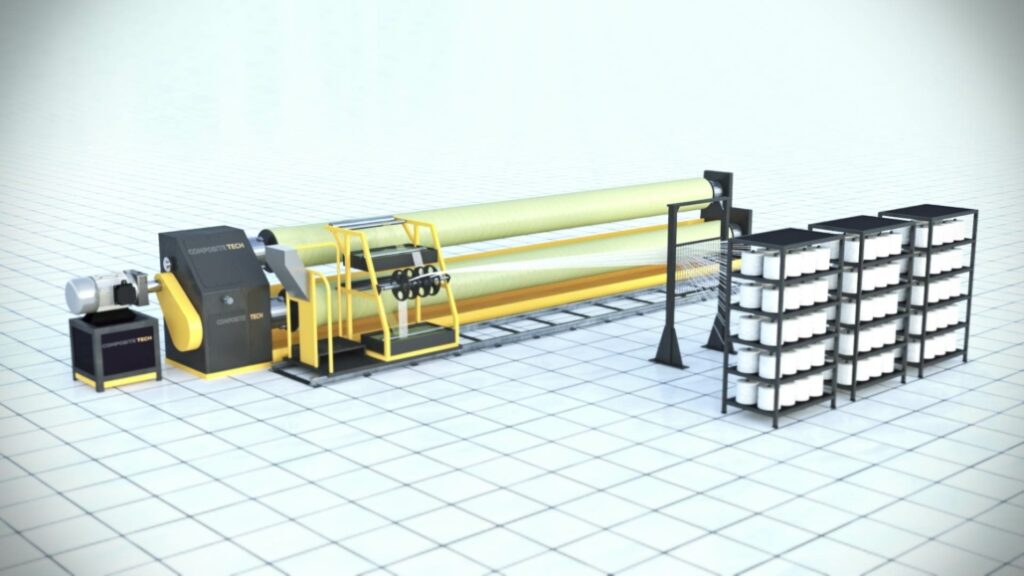

Технические характеристики линии по производству стеклопластиковых труб

| Цель: | производство стеклопластиковых труб |

| Диаметр изделий: | До 1000мм |

| Напряжение: | 380 В / 50 Гц |

| Власть: | 30 кВт |

| Производительность линии: | Зависит от диаметра |

| Длина оборудования: | 12м |

| Ширина: | 2,5м |

| Высота: | 2,8м |

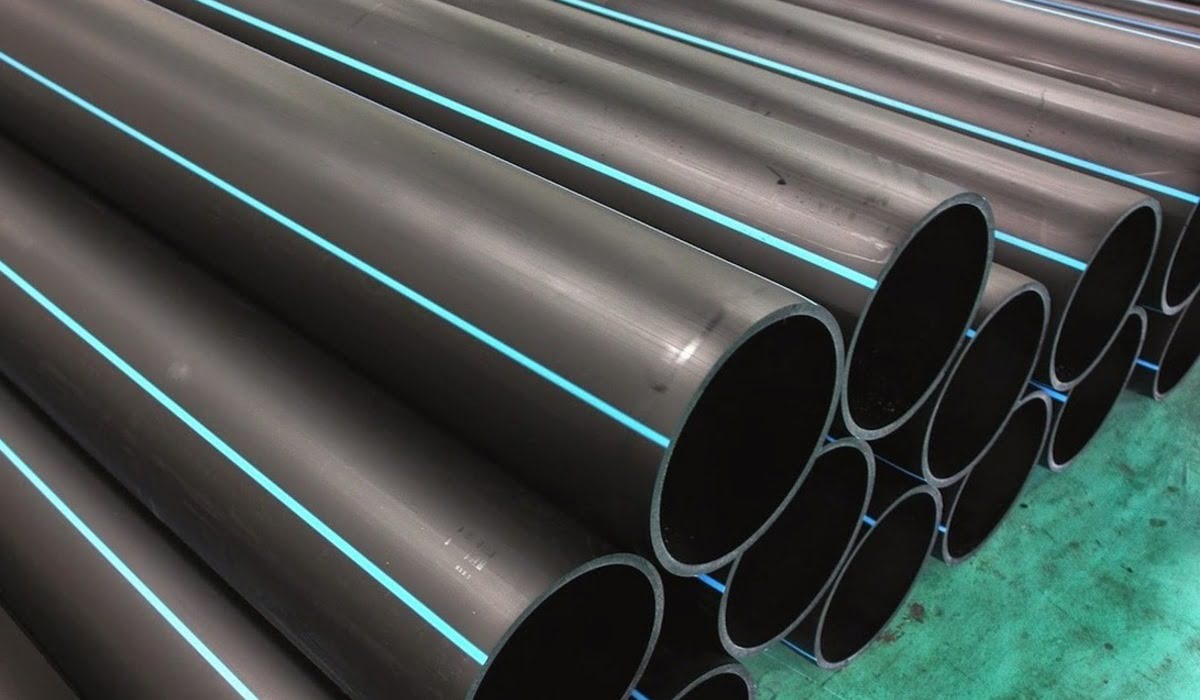

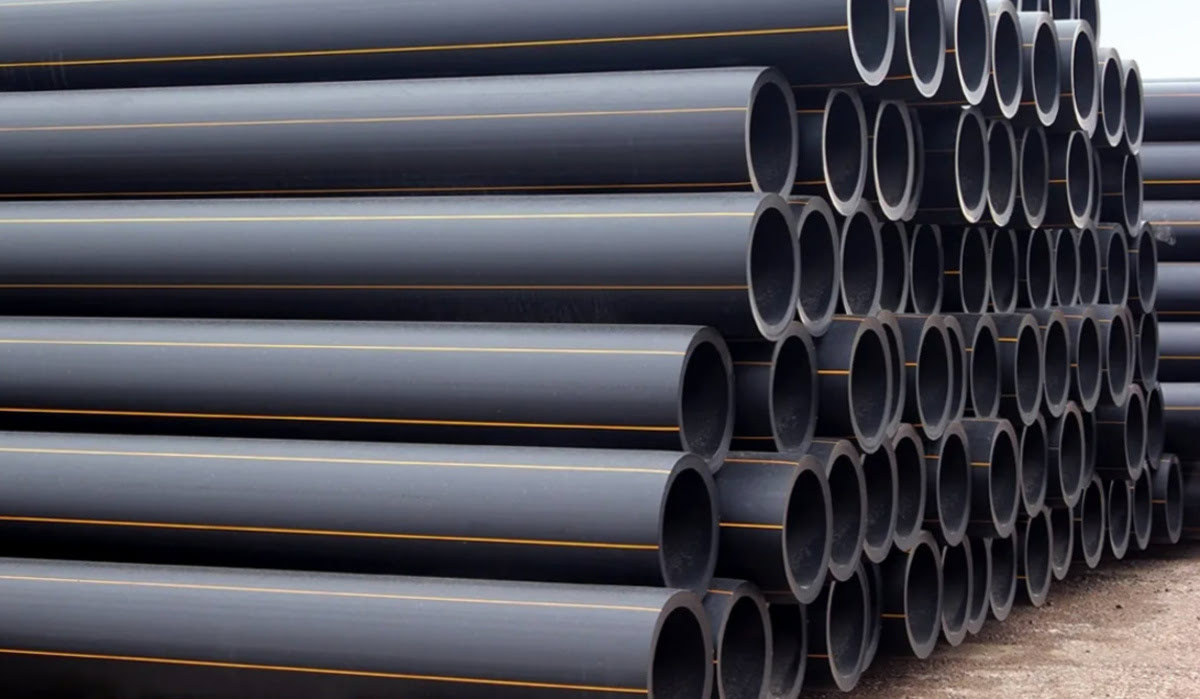

Преимущества труб FRP по сравнению с обычными трубами:

- Коррозионная стойкость – Трубы FRP устойчивы к коррозии, возникающей под воздействием морской воды, химикатов, нефти, газа, тепла, ультрафиолетовых лучей и экстремальных условий окружающей среды.

- Устойчивость – Конечный продукт наших линий по производству стеклопластиковых труб способствует устойчивому развитию строительства, направляя отрасль в сторону более экологичных решений.

- Прочность и легкость – Трубы FRP обладают высокой прочностью на разрыв, при этом применение таких труб не требует использования связующих веществ, болтовых соединений или сварки. Трубы GFRP легче по сравнению с трубами из ковкого чугуна, мягкой стали и HDPE. Небольшой вес обеспечивает простоту обращения, транспортировки и монтажа. Эти качества делают трубы FRP намного более долговечными, надежными и экономичными, чем обычные трубы.

- Сопротивление давлению – Высокая жесткость и высокая способность к сжатию труб FRP предотвращают разрыв труб из-за колебаний давления воды. Они имеют меньшую толщину стенки, что упрощает размещение и монтаж таких труб. Трубы FRP устойчивы к истиранию и растрескиванию, обладают нулевой инфильтрацией, низкой обработкой и отсутствием загрязнения грунтовых вод. Дополнительным преимуществом труб GRP является поглощение давления: они рассчитаны на поглощение 40% давления скачка давления без повышения класса давления.

- Гидравлическая эффективность – Трубы из стеклопластика имеют гладкую внутреннюю поверхность, что способствует отличным гидравлическим характеристикам, высокой пропускной способности и низкому трению. Это также обуславливает низкие потери напора и затраты на перекачку. Внутренняя температура труб из стеклопластика остается постоянной благодаря их уникальным термическим свойствам. Обычные трубы из стеклопластика не проводят электричество и обладают гораздо лучшими электрическими свойствами, чем их стальные аналоги. Однако, если требуется электропроводность, можно добавить проводящее армированное волокно или наполнители в процессе изготовления.

Производство стеклопластиковой арматуры под ключ!

Сопоставляя цену продажи арматуры из стеклопластика со стальной арматурой, вы получаете прибыль, превышающую 120%!

Получите свою производственную линию всего через 2 месяца после размещения заказа и верните свои инвестиции всего за 3 месяца после запуска производства.

Применение труб FRP

Трубы из стеклопластика обычно используются в подземных и надземных сооружениях, подводных сооружениях и для ремонта, где важны высокая износостойкость, гидравлическая эффективность и прочность.