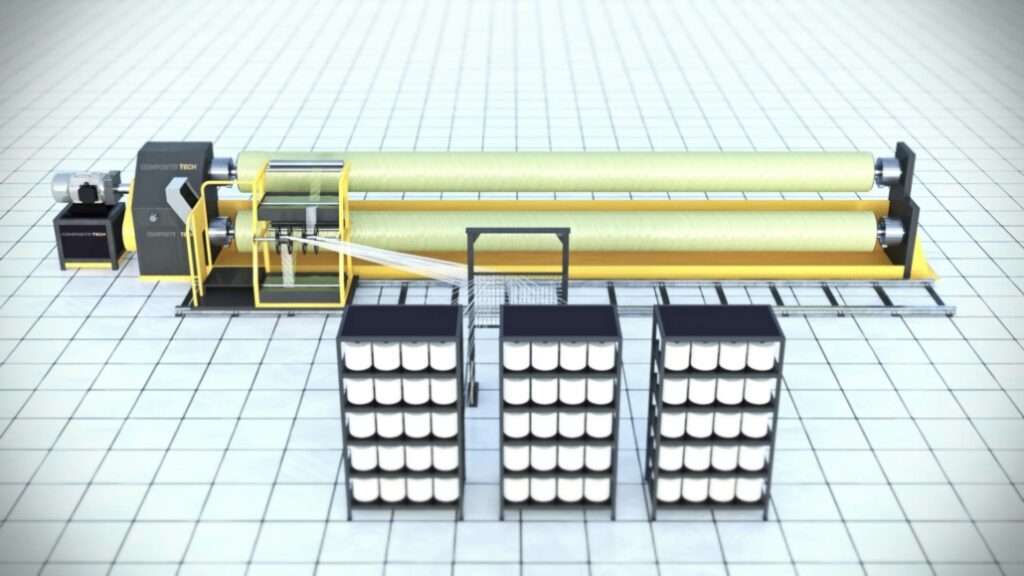

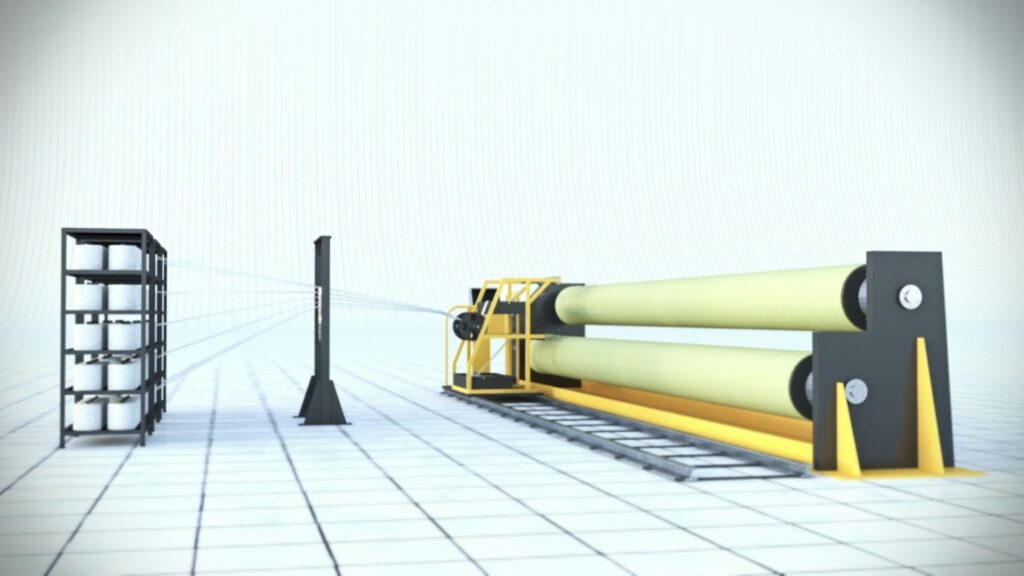

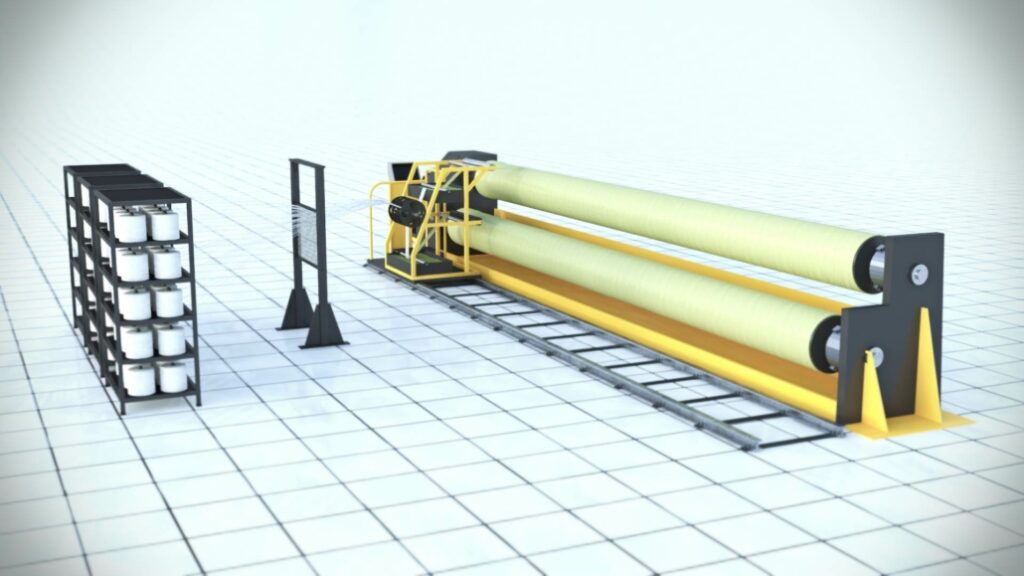

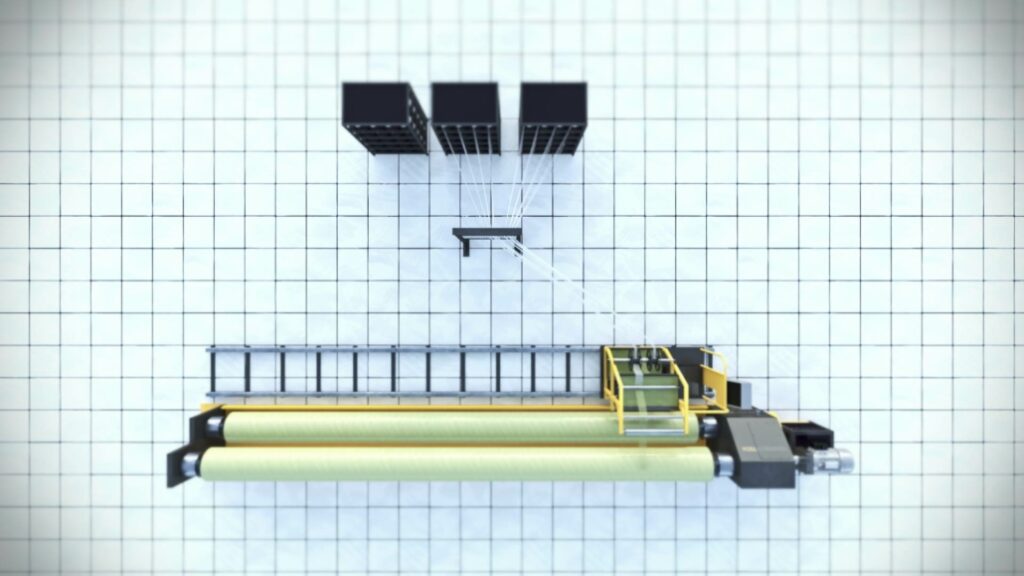

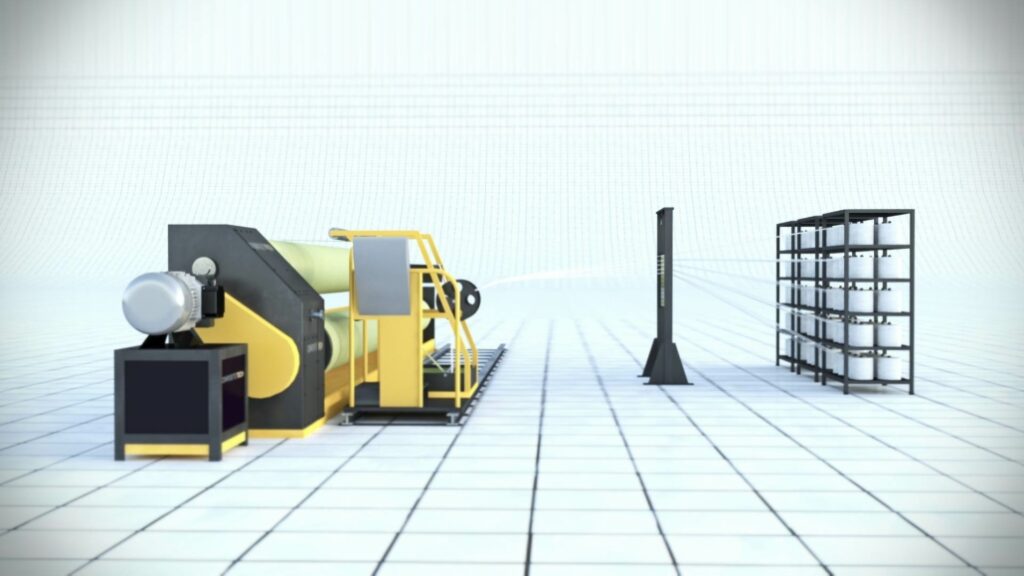

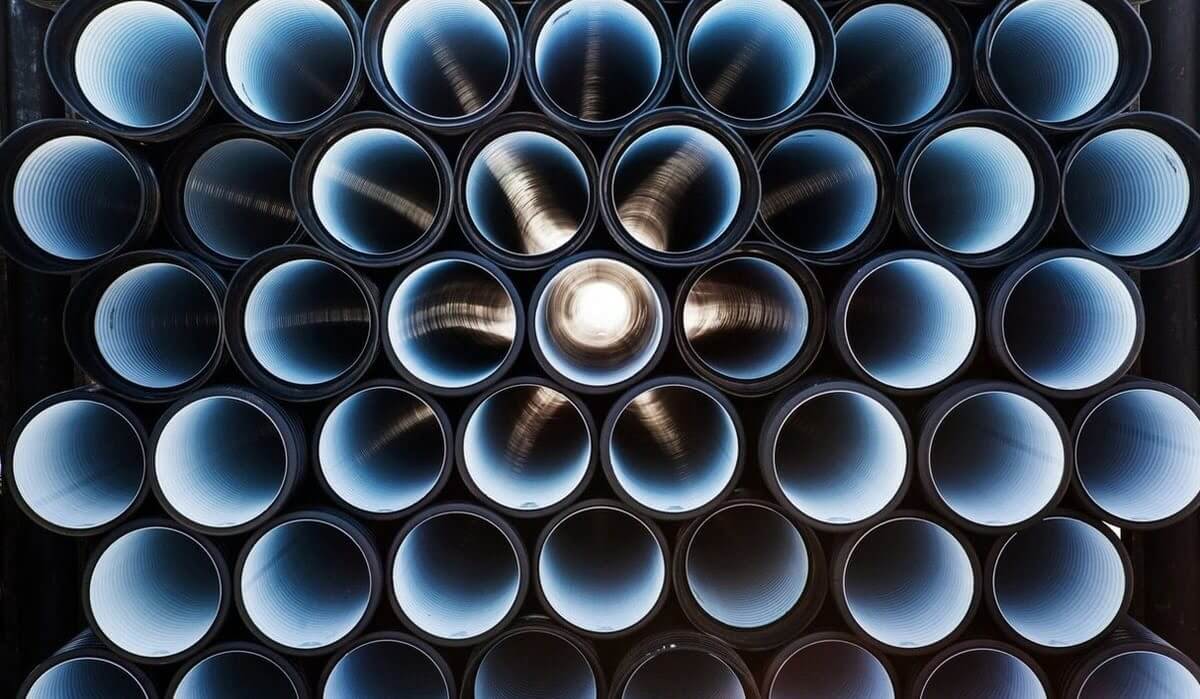

A Composite-Tech é uma fornecedora global de linhas de produção de vergalhões e telas de PRFV. Desta vez, levamos a indústria de compósitos ainda mais longe, apresentando nossa recém-desenvolvida linha de produção de tubos de PRFV. Assim como os vergalhões e telas de PRFV, os tubos feitos de fibra de vidro apresentam inúmeras vantagens em relação aos tubos convencionais de aço, cimento, cobre e ferro para serviços pesados, elevando a indústria a um novo patamar de sustentabilidade e eficiência.

As linhas de produção de tubos GFRP da Composite-Tech oferecem:

- Automação completa

- Produção de tubos com diâmetro de até 1000mm

- Tecnologia de produção com boa relação custo-benefício

- Processo de produção sustentável

Nosso equipamento é projetado para ser confiável, altamente produtivo e único na tecnologia que utilizamos! Todos os nossos desenvolvimentos e inovações são patenteados, o que garante não apenas alta eficácia do seu investimento, mas também um mercado livre de concorrência. Além disso, para garantir a confiabilidade de todos os módulos da linha de produção, usamos apenas os componentes que passaram por nossos rigorosos testes e avaliações de desempenho.

Ao adquirir o equipamento de produção de vergalhões de FRP da Composite-Tech, nossos clientes também têm os seguintes resultados:

- Assistência na seleção de instalações especiais

- Nossos especialistas realizam instalação de equipamentos e trabalhos de comissionamento

- Treinamento de pessoal

- Aconselhamento contínuo aos seus especialistas técnicos

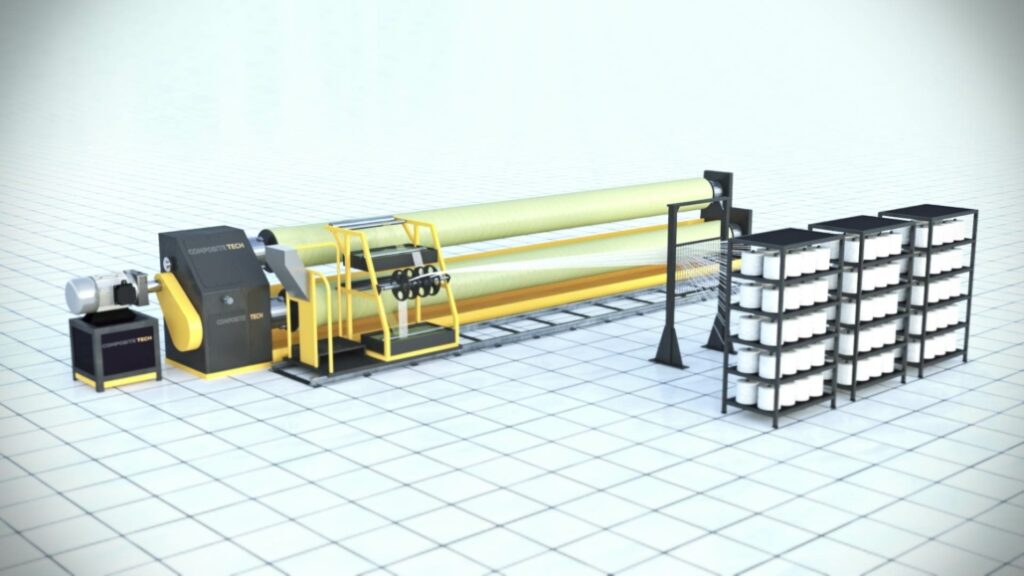

Características técnicas

Características técnicas da linha de produção de tubos de PRFV

| Propósito: | produção de tubos de fibra de vidro |

| Diâmetro dos produtos: | Até 1000 mm |

| Tensão: | 380 V / 50 Hz |

| Poder: | 30 kW |

| Desempenho da linha: | Depende do diâmetro |

| Comprimento do equipamento: | 12m |

| Largura: | 2,5 m |

| Altura: | 2,8 m |

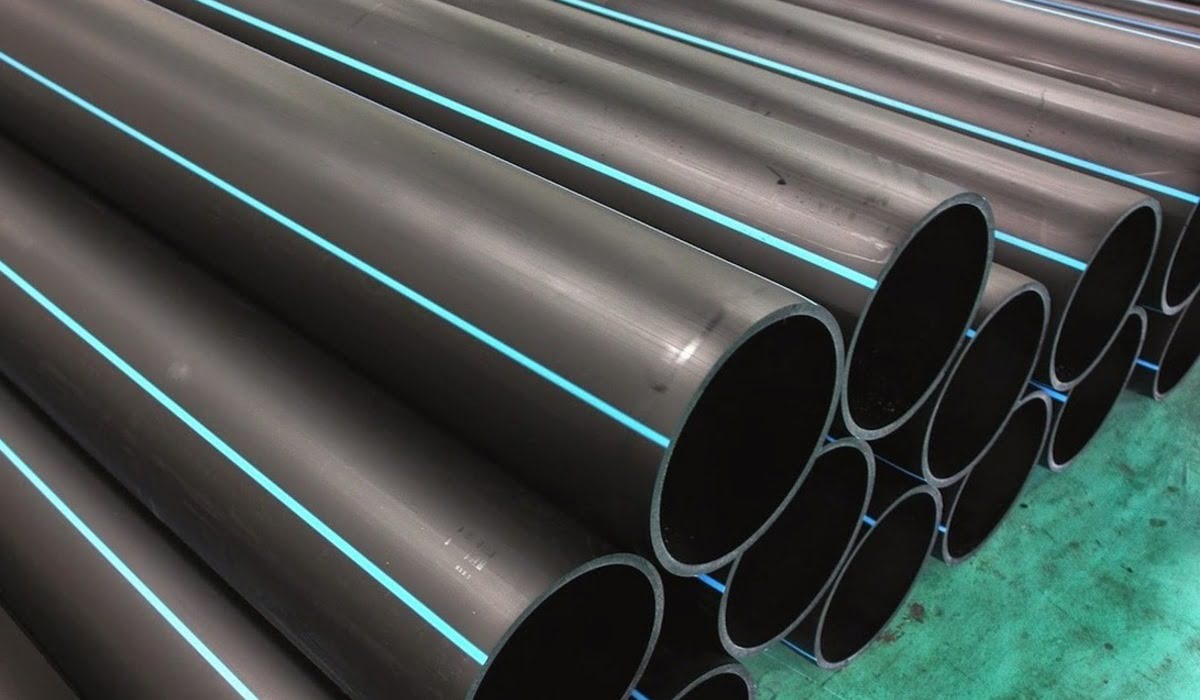

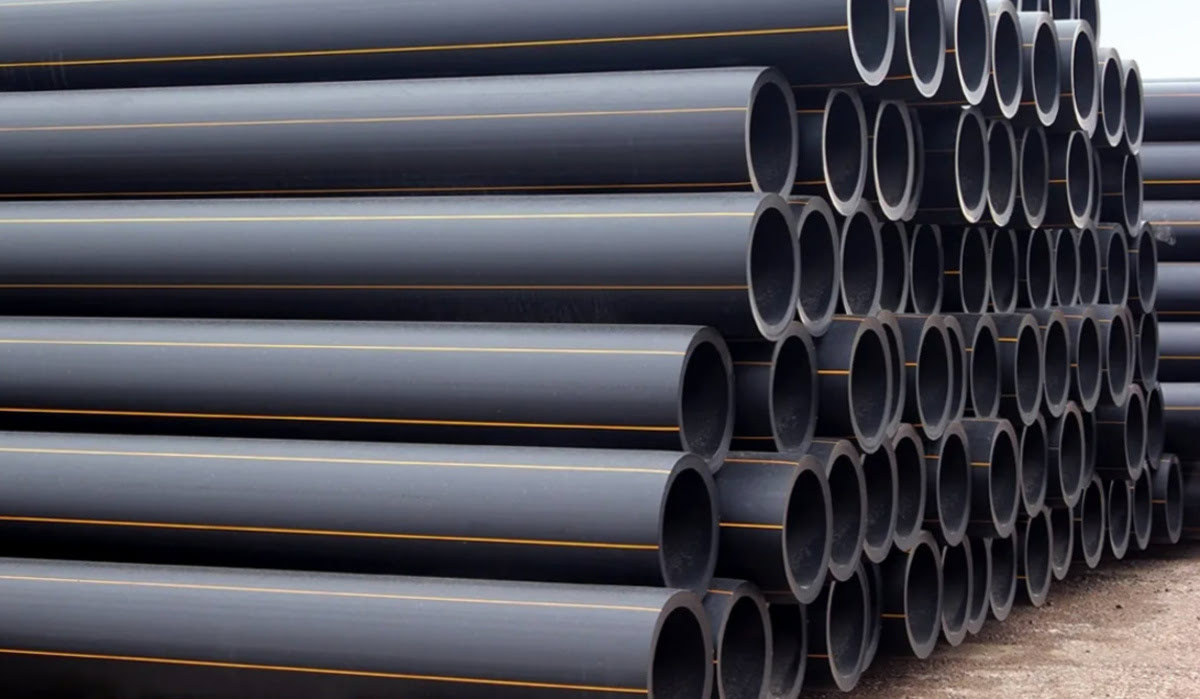

Vantagens dos tubos de PRFV em comparação aos tubos convencionais:

- Resistência à corrosão – Os tubos de FRP são resistentes à corrosão resultante da água do mar, produtos químicos, óleo, gás, calor, raios UV e condições ambientais extremas.

- Sustentabilidade – O produto final de nossas linhas de produção de tubos de PRFV auxilia na sustentabilidade da construção, direcionando a indústria para uma solução mais ecológica.

- Força e Leveza – Os tubos de PRFV apresentam alta resistência à tração, e sua aplicação dispensa o uso de agentes de ligação, parafusos ou solda. Os tubos de PRFV são leves em comparação com tubos de ferro dúctil, aço carbono e PEAD. Seu baixo peso garante fácil manuseio, transporte e instalação. Essas qualidades tornam os tubos de PRFV muito mais duráveis, confiáveis e econômicos do que os tubos convencionais.

- Resistência à pressão – A alta rigidez e a alta capacidade de carga compressiva dos tubos de PRFV evitam o rompimento dos tubos devido a flutuações na pressão da água. Eles possuem uma espessura de parede menor, o que simplifica a colocação e a instalação desses tubos. Os tubos de PRFV são resistentes à abrasão e à fissuração, apresentam infiltração zero, baixo custo de tratamento e ausência de poluição das águas subterrâneas. Uma vantagem adicional dos tubos de PRFV é a absorção de pressão: eles são projetados para absorver 40% da pressão de pico, sem aumentar a classe de pressão.

- Eficiência hidráulica – Os tubos de PRFV possuem uma superfície interna lisa, o que proporciona excelentes características hidráulicas, alta capacidade de vazão e baixo atrito. Isso também garante baixas perdas de carga e custos de bombeamento. A temperatura interna dos tubos de PRFV permanece constante devido às suas propriedades térmicas únicas. Os tubos de PRFV comuns não conduzem eletricidade e apresentam propriedades elétricas muito melhores do que seus equivalentes de aço. No entanto, se for necessária condutividade elétrica, é possível adicionar fibras reforçadas condutoras ou enchimentos durante o processo de fabricação.

Produção de vergalhão GFRP chave na mão em Portugal!

Ao combinar o preço de venda do vergalhão GFRP com o vergalhão de aço, você obtém uma margem de lucro de mais de 120%!

Obtenha sua linha de produção em apenas 2 meses após fazer um pedido e retorne seu investimento em apenas 3 meses após o lançamento da produção.

Aplicação de tubos de FRP

Tubos de FRP são comumente usados em aplicações subterrâneas e superficiais, aplicações subaquáticas e revestimentos, para os quais alta resistência, eficiência hidráulica e alta resistência são essenciais.