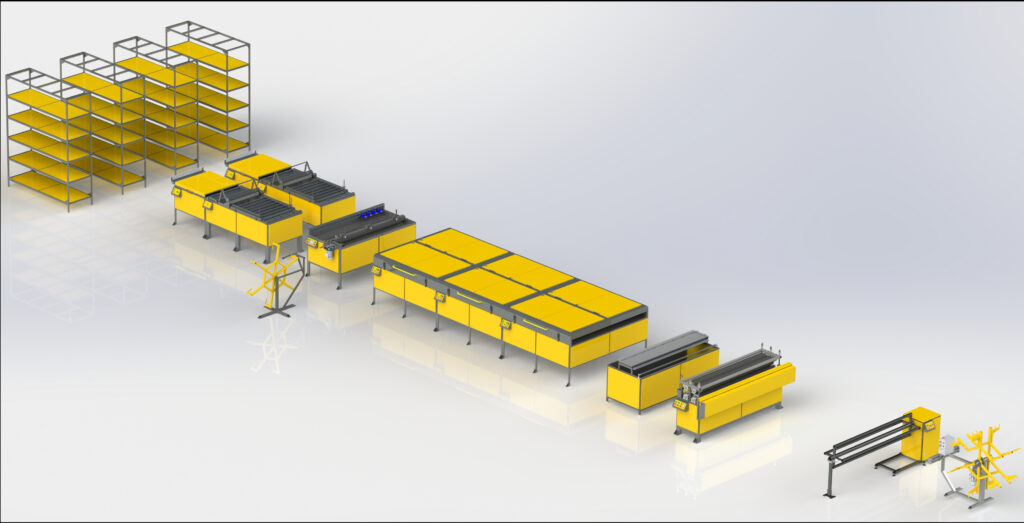

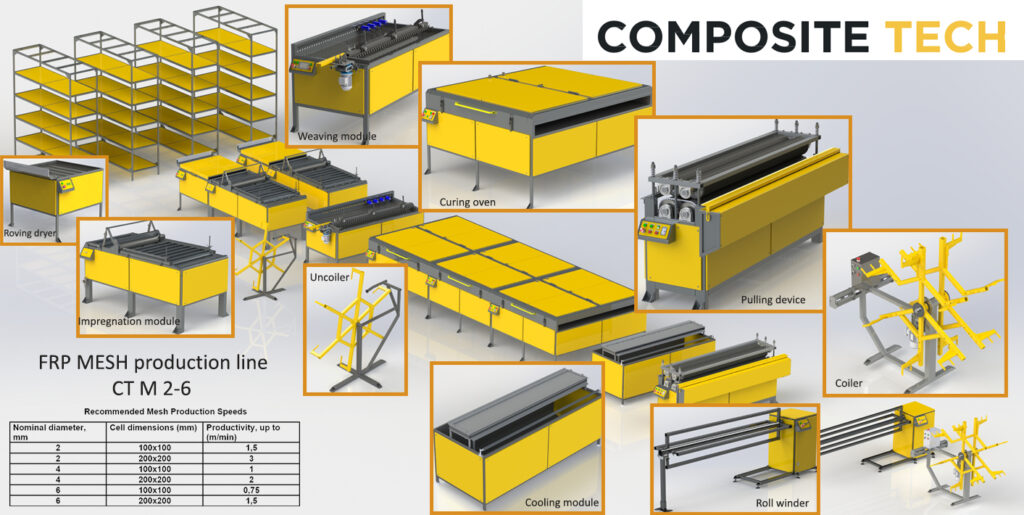

The CT M ST2-6 is a high-tech machine designed for the production of fiberglass mesh with a width of up to 2 meters and rod diameters up to 6 mm with customizable mesh sizes. This machine is ideal for those looking to establish a profitable fiberglass mesh production business, providing high productivity and quality products.

Advantages of CT M ST2-6

Ensures high product quality and optimal productivity, making it the best choice for your business.

The machine allows you to adjust production parameters to meet your needs, providing flexibility and efficiency in operation.

The use of the latest technologies and materials guarantees the durability and reliability of the equipment.

1. Creel

- Função: Device for installing roving bobbins and creating pre-tension of the threads.

2. Roving Heater

- Função: Provides leveling and drying of roving threads, evenly distributing heat.

3. Impregnation Module

- Função:Impregnates roving threads with resin and presses them, minimizing polymer consumption.

4. Weaving Module

- Função: Performs winding of the periodic profile and mesh weaving.

5. Oven

- Função: Polymerizes the resin, completing the mesh formation process.

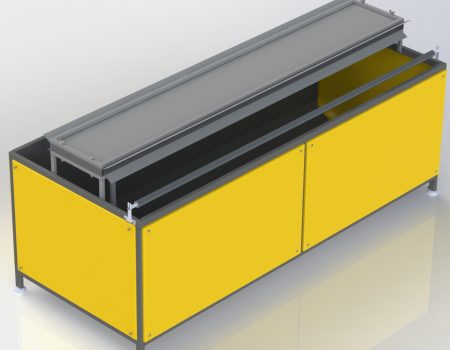

6. Cooling Module

- Função: Cools the finished fiberglass products.

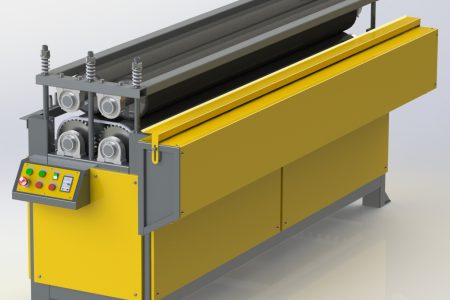

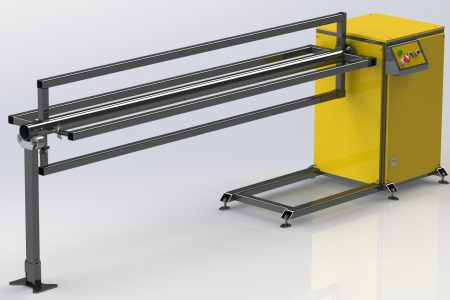

6. Pulling Device

- Função: Ensures pulling and cutting of the mesh.

6. Roll Winder

- Função: Optionally winds the finished mesh into rolls.

6. Automatic Coiler

- Função: Winds the mesh onto a spool.

6. Uncoiler

- Função: Ensures unwinding of the mesh for further processing.

Performance

| Nominal Diameter (mm) | Mesh Size (mm) | Productivity (m/min) |

|---|---|---|

| 2 | 100x100 | 1.5 |

| 2 | 200x200 | 3 |

| 4 | 100x100 | 1 |

| 4 | 200x200 | 2 |

| 6 | 100x100 | 0.75 |

| 6 | 200x200 | 1.5 |

Especificações técnicas do CT2

| Parâmetro | Valor |

|---|---|

| Rod diameter (mm) | 2 - 6 |

| Mesh sizes (mm) | 50x50, 100x100, 200x200 |

| Dimensions (LxWxH) | 25 m x 6.5 m x 2.5 m |

| Power consumption | 40 kW |

| Power supply | 380 V, 50 Hz |

| Equipment weight | 5000 kg |

| Mesh width | Up to 2 m |

The CT M ST2-6 machine from Composite-Tech is an investment in your future, allowing you to produce high-quality fiberglass mesh, meeting the demands of the most discerning customers, and ensuring high income for your business.

Não perca a oportunidade de tornar seu negócio mais lucrativo com as tecnologias avançadas da Composite-Tech! Contate-nos para saber mais e fazer um pedido.