Na última década, o setor de construção dos EUA enfrentou enormes desafios: infraestrutura envelhecida, corrosão das armaduras de aço e a necessidade de materiais sustentáveis com maior vida útil. As barras de reforço de polímero reforçado com fibra de vidro (GFRP) surgiram como uma das alternativas mais confiáveis ao aço tradicional.

No entanto, o projeto com reforço de GFRP nos EUA deve seguir rigorosamente ACI 440.11-22 – Requisitos do Código de Construção para Concreto Estrutural Reforçado com Barras de PRFV.

Este artigo explica o que o ACI 440.11-22 significa para engenheiros, empreiteiros e proprietários de projetos, e como projetar corretamente estruturas de concreto com barras de GFRP que atendam aos códigos dos EUA, aos requisitos do DOT e aos padrões ASTM.

Por que vergalhões de PRFV?

O reforço de aço tem sido a espinha dorsal do concreto por mais de um século, mas apresenta um problema grave: a corrosão. Sais de degelo, ambientes marinhos e exposição à umidade reduzem drasticamente a vida útil.

Em contraste, vergalhões de fibra de vidro (GFRP) oferece:

- Resistência à corrosão 100% – sem ferrugem, mesmo em ambientes ricos em cloreto.

- Alta resistência à tração – 2–3x mais forte que o aço em peso.

- Peso leve – 75% mais leve que o aço, reduzindo custos de manuseio e envio.

- Neutralidade eletromagnética – perfeito para hospitais, laboratórios e data centers.

- Sustentabilidade – menos cobertura de concreto necessária, menor pegada de CO₂, ciclo de vida mais longo.

O que é ACI 440.11-22?

ACI 440.11-22 é o código oficial do Instituto Americano de Concreto que estabelece como projetar e detalhar estruturas de concreto reforçadas com barras de PRFV. Ele garante:

- Metodologia de design uniforme nos EUA

- Margens de segurança baseadas no comportamento do material do GFRP.

- Aceitação de vergalhões de PRFV em códigos de construção nacionais e estaduais.

Normas e códigos relacionados:

- ASTM D7957 – Especificação para barras redondas sólidas de GFRP.

- ICC-ES AC454 – Critérios de aceitação para barras de PRFV em concreto.

- IBC 2024 – Inclui referências ao reforço de FRP.

- Listas de produtos aprovados pelo DOT (APL) – Necessário para pontes e projetos de infraestrutura.

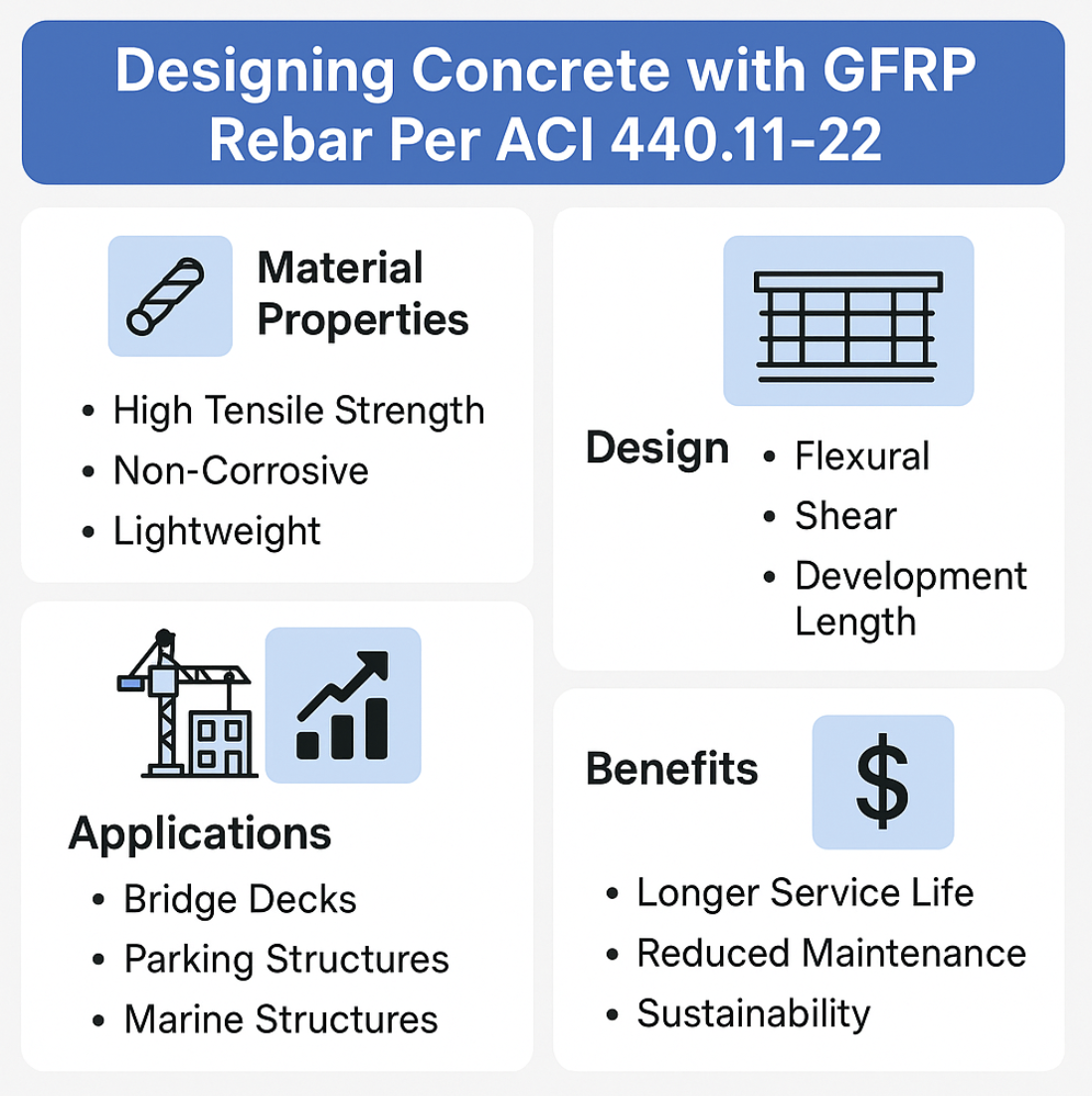

Âmbito do ACI 440.11-22

ACI 440.11-22 permite vergalhões GFRP em:

- Tabuleiros de pontes e estruturas de transporte.

- Garagens de estacionamento com alta exposição a sais de degelo.

- Estruturas marinhas como paredões e píeres.

- Fundações, lajes e paredes em projetos residenciais e comerciais.

Limitações:

- Zonas sísmicas: algumas restrições se aplicam em categorias de projeto sísmico alto.

- Resistência ao fogo: O GFRP amolece sob temperaturas extremas, exigindo detalhes especiais.

- Ancoragem e curvas: raios maiores em comparação ao aço.

Princípios-chave de design

1. Propriedades do material

- Resistência à tracção: tipicamente 600–1200 MPa.

- Módulo de elasticidade: ~45–60 GPa (¼ de aço).

- Curva tensão-deformação: elástico linear até a ruptura (sem patamar de escoamento).

2. Projeto Flexural

- Resistência à flexão baseada em condições de falha balanceadas.

- O esmagamento do concreto rege o projeto; a falha de tensão do GFRP deve ser evitada.

3. Projeto de cisalhamento

- O reforço de cisalhamento (estribos) pode ser de PRFV ou aço, dependendo dos requisitos do projeto.

- Regras especiais de detalhamento garantem ductilidade.

4. Facilidade de manutenção

- As verificações de deflexão são críticas devido à menor rigidez.

- O controle da largura da fissura requer diâmetros de barra maiores ou espaçamento mais próximo.

5. Comprimento de desenvolvimento e emenda

- Comprimentos de emenda de sobreposição são mais longos que os do aço.

- Superfícies revestidas com areia ou enroladas helicoidalmente melhoram a aderência ao concreto.

Construção e Detalhamento

- Raio de curvatura: tipicamente ≥ 10 × diâmetro da barra.

- Corte: somente com serras de lâmina diamantada.

- Colocação: Recomenda-se o uso de cadeiras de plástico ou suportes não corrosivos.

- Amarração: abraçadeiras de plástico ou revestidas são preferidas.

Exemplo prático

Imagine projetar um laje do tabuleiro da ponte:

- Usando vergalhões de PRFV #3 (3/8 pol.) espaçados em centros de 6 pol.

- O ACI 440.11 fornece equações para verificar flexão, cisalhamento e capacidade de manutenção.

- Em comparação com o aço, a espessura da cobertura pode ser reduzida, estendendo a vida útil do deck de ~30 anos para mais de 75 anos.

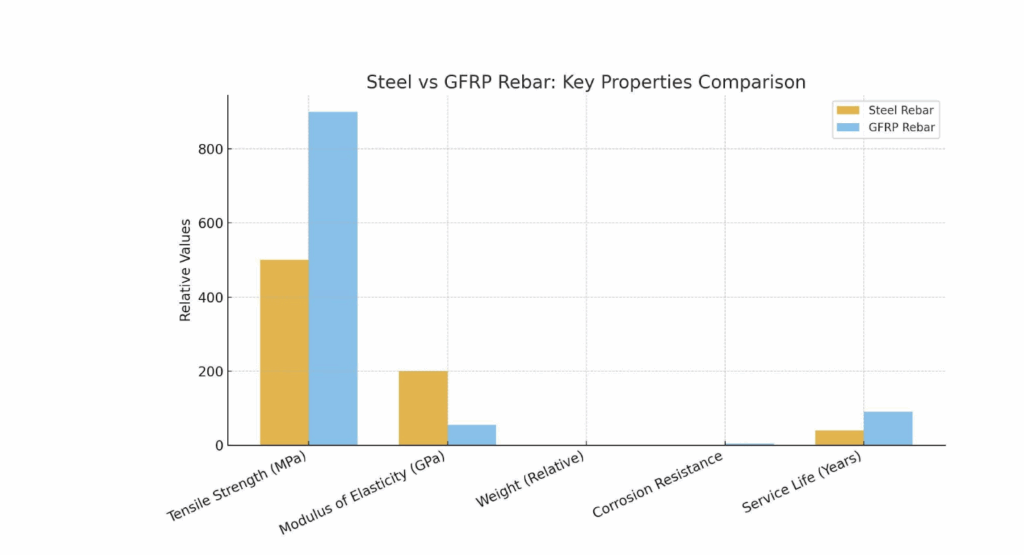

Comparação: vergalhões de aço vs. GFRP

| Propriedade | Barra de aço | Vergalhões de PRFV |

| Resistência à tracção | 400–600 MPa | 600–1200 MPa |

| Módulo de Elasticidade | ~200 GPa | 45–60 GPa |

| Resistência à corrosão | Baixo | Excelente (100%) |

| Peso | 1.0 | 0,25 (4× mais leve) |

| Vida útil | 30–50 anos | 75–100 anos |

| Custo por unidade de peso | Mais baixo | Um pouco mais alto |

| Custo do ciclo de vida | Mais alto (devido a reparos) | Inferior (sem manutenção) |

Saber mais:

- Vergalhões de PRFV vs. vergalhões de aço: comparação técnica

- Vergalhões de PRFV vs. Aço: Custo, Resistência e Benefícios a Longo Prazo na Construção Moderna

- Vergalhões de FRP vs. Vergalhões de aço

Conformidade e Certificação

Para usar Vergalhões de PRFV nos EUA projetos, os fornecedores devem fornecer:

- Certificados ASTM D7957 para conformidade material.

- Relatórios de Avaliação ICC-ES (ER) sob AC454.

- Aprovações do DOT (por exemplo, FDOT APL, TxDOT, Colorado DOT).

Benefícios para o mercado dos EUA

- Maior vida útil para infraestrutura (pontes, rodovias, marinha).

- Redução dos orçamentos de manutenção para os municípios.

- Alinhamento com metas de construção sustentável e programas federais de infraestrutura.

Conclusão

A ACI 440.11-22 tornou o uso de vergalhões de PRFV totalmente reconhecido nos Estados Unidos, proporcionando confiança aos engenheiros e uma vantagem competitiva aos empreiteiros. Com desempenho livre de corrosão, vida útil mais longa e conformidade com os códigos americanos, o PRFV não é apenas uma alternativa — é o futuro do concreto armado.

Se você é um engenheiro, contratante ou investidor dos EUA que deseja adotar vergalhões de PRFV em seus projetos ou montar uma unidade de produção, entre em contato com a Composite-Tech hoje. Nós fornecemos líderes mundiais equipamentos para produção de vergalhões e telas de PRFV, treinamento completo e suporte com certificação.

Perguntas frequentes

As barras de reforço GFRP são aprovadas pela ACI?

Sim, ACI 440.11-22 é o código de projeto oficial para GFRP nos EUA

Posso usar vergalhões de fibra de vidro em fundações residenciais?

Sim, a norma ACI 440.11 abrange fundações, lajes e paredes. Sempre verifique a aceitação do código de construção local.

Qual é o comprimento da emenda sobreposta para GFRP?

Normalmente 40–60 diâmetros de barra, dependendo do tamanho da barra e do acabamento da superfície.

As barras de fibra de vidro são resistentes ao fogo?

Possui menor resistência ao fogo que o aço; medidas adicionais são necessárias em ambientes de alta temperatura.

Saber mais:

- Entendendo a norma ACI 440.11-22 para fabricantes de vergalhões de GFRP

- Composite-Tech e FRP Institute anunciam parceria estratégica para redefinir padrões globais na indústria de reforço de FRP

- Perguntas frequentes sobre equipamentos Composite-Tech e tecnologia GFRP

- Vergalhão de fibra de vidro #3 (3/8 pol.): preço, peso e casos de uso reais nos EUA

- Preço do vergalhão de GFRP por pé e por kg nos EUA (detalhamento de custos para 2026)

- Documentação técnica