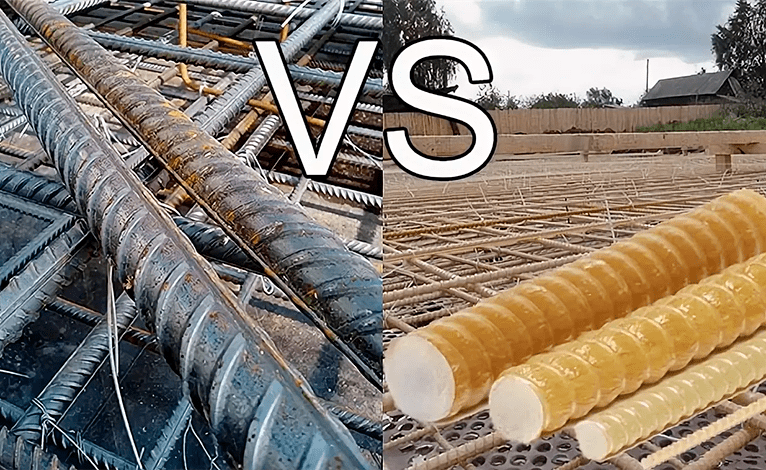

Na engenharia civil moderna e no desenvolvimento de infraestrutura, a seleção do material de reforço tem um profundo impacto na durabilidade, no custo e no desempenho geral das estruturas de concreto. Tradicionalmente, as barras de aço têm sido a escolha dominante devido à sua resistência e disponibilidade. No entanto, as barras de polímero reforçado com fibra de vidro (GFRP) têm ganhado considerável atenção nos últimos anos como uma alternativa superior para aplicações específicas. Este artigo apresenta uma comparação abrangente e baseada em dados entre barras de GFRP e barras de aço, considerando propriedades mecânicas, durabilidade, peso, impacto econômico e exemplos específicos de projetos.

Comparação de Propriedades Mecânicas

A resistência mecânica é o principal fator na escolha do reforço. Abaixo, uma tabela comparativa das principais características mecânicas:

| Propriedade | Vergalhão de aço (A615 Gr.60) | Vergalhões de PRFV |

| Resistência à tracção | ~550 MPa | 1000–1500 MPa |

| Módulo de Elasticidade | ~200 GPa | 60–80 GPa |

| Limite de escoamento | ~500 MPa | Não aplicável (quebradiço) |

| Densidade | ~7850 kg/m³ | ~1900 kg/m³ |

Interpretação:

- O GFRP tem uma resistência à tração 2–3 vezes maior.

- O módulo de elasticidade do GFRP é cerca de 4 a 5 vezes menor, resultando em maior deflexão sob carga, o que é essencial no projeto.

Caso de uso:

Em tabuleiros de pontes de grande extensão ou barreiras rodoviárias, o GFRP pode suportar cargas de tração mais altas, mas requer um projeto de seção ajustado devido à menor rigidez.

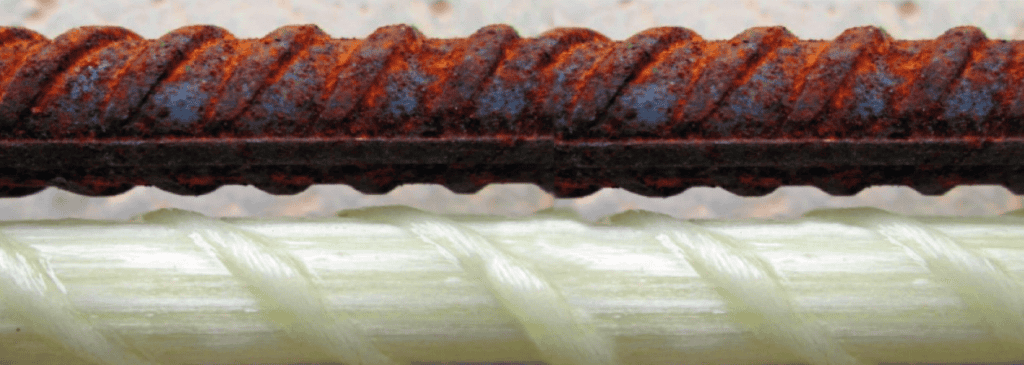

Resistência à corrosão e vida útil

Uma das maiores desvantagens do aço é sua suscetibilidade à corrosão, especialmente em ambientes ricos em cloreto, como estruturas marinhas e regiões de degelo.

| Parâmetro | Aço | PRFV |

| Resistência à corrosão | Pobre | Excelente (não corrosivo) |

| Vida útil em condições adversas | 20–30 anos | 80–100+ anos |

Estudo de caso: Marina del Rey Seawall, Califórnia

- O reforço de aço original corroeu em 25 anos.

- Substituído por vergalhões de PRFV, com expectativa de durar mais de 100 anos sem corrosão.

Conclusão: O GFRP é o vencedor claro em qualquer estrutura exposta a sal, umidade, produtos químicos ou umidade extrema.

Peso e eficiência de manuseio

O GFRP é significativamente mais leve que o aço, o que afeta diretamente o custo de envio, o tempo de manuseio e a complexidade da instalação.

| Propriedade | Vergalhões de aço | Vergalhões de PRFV |

| Peso Relativo | 100% | ~25% (1/4 de aço) |

| Manuseio manual | Requer maquinário | Trabalho individual |

| Custo de transporte | Alto | Até 50% mais baixo |

Exemplo: Em regiões montanhosas como o Nepal ou nações insulares, empresas de construção relatam economias de logística de mais de 30% usando GFRP.

Propriedades eletromagnéticas e térmicas

O GFRP é não condutor e termicamente estável.

| Característica | Aço | PRFV |

| Condutividade elétrica | Alto | Nenhum |

| Condutividade térmica | Alto | Muito baixo |

| Interferência de campo magnético | Sim | Nenhum |

Aplicações:

- Salas de ressonância magnética em hospitais

- Subestações e usinas de energia

- Túneis ferroviários

Nesses ambientes, o GFRP garante segurança e integridade funcional.

Comparação de custos e economia do ciclo de vida

Embora o custo inicial do GFRP seja normalmente 1,5 a 2 vezes maior que o do aço, seu custo total do ciclo de vida (LCC) é menor em muitos casos.

| Fase | Vergalhões de aço | Vergalhões de PRFV |

| Custo do material (inicial) | $0,75/kg | $1,5–2,0/kg |

| Custo de instalação | Mais alto | Mais baixo |

| Custo de manutenção | Muito alto | Mínimo |

| Total LCC (50 anos) | 100% | ~65–75% |

Exemplo: Uma ponte de concreto de 1 km na Flórida exigiu $1,2M em reparos de corrosão após 20 anos. Uma ponte semelhante construída com PRFV não apresentou degradação após 25 anos.

Limitações de projeto do GFRP

Apesar dos benefícios, o GFRP tem algumas restrições de projeto:

- Modo de falha frágil: Não há patamar de rendimento, então os fatores de segurança devem ser ajustados.

- Módulo baixo: Aumento da deflexão, a menos que compensado pela geometria.

- Sem flexão no local: Deve ser pré-fabricado conforme especificação.

Soluções:

- Utilize estribos e telas de GFRP dobrados.

- Aplique códigos de projeto composto (ACI 440.1R) para planejamento estrutural seguro.

Padrões e Conformidade

O GFRP é reconhecido pelos principais códigos internacionais:

- ACI 440.1R (EUA) – Diretrizes de projeto para reforço de FRP

- CSA S807 / S806 (Canadá) – Concreto Armado com PRFV

- CNR-DT 203 (Itália) – Orientação europeia

Esses padrões fornecem regras claras para uso seguro e promovem a adoção global.

Conclusão Final

Vergalhões de PRFV não são um substituto universal para o aço, mas em ambientes corrosivos, remotos ou eletromagneticamente sensíveis, eles oferecem maior longevidade, menores custos de ciclo de vida e manuseio mais fácil.

Com a crescente demanda por infraestrutura e a resiliência climática se tornando uma prioridade, o GFRP é um investimento à prova de futuro para muitos tipos de construção.

Composite-Tech fornece equipamentos de última geração para a produção automatizada de Vergalhões de PRFV e malha, ajudando empresas de construção em todo o mundo a fazer a transição para soluções de reforço mais inteligentes, fortes e sustentáveis.