Branża budowlana zawsze była na czele innowacji, nieustannie poszukując materiałów i metod, które optymalizują wytrzymałość, trwałość i opłacalność. Jednym z najbardziej rewolucyjnych materiałów, które wywarły znaczący wpływ w ostatnich latach, jest zbrojenie z polimeru wzmacnianego włóknami (FRP), które zmieniło sposób, w jaki inżynierowie budowlani i specjaliści od budownictwa postrzegają zbrojenie. Przyjrzyjmy się globalnym doświadczeniom związanym z wykorzystaniem prętów zbrojeniowych FRP i zrozumiejmy ich znaczenie.

Treść

Czym jest zbrojenie FRP?

W swojej istocie pręty zbrojeniowe FRP są materiałem kompozytowym wykonanym z matrycy polimerowej wzmocnionej włóknami, zazwyczaj szklanymi, węglowymi lub bazaltowymi. W przeciwieństwie do tradycyjnych prętów stalowych, pręty zbrojeniowe kompozytowe są odporne na korozję i oferują wyższy stosunek wytrzymałości do masy. Ta wyjątkowa kompozycja zapewnia im szereg korzyści, które uczyniły je szczególnie atrakcyjnymi do różnych zastosowań budowlanych.

Pomysł na zbrojenie kompozytowe nie jest nowy. Historycznie rzecz biorąc, cywilizacje używały materiałów takich jak bambus jako zbrojenia, ze względu na jego naturalną wytrzymałość i elastyczność. Jednak współczesna wersja zbrojenia kompozytowego – pręty z włókna szklanego – powstała w połowie XX wieku, kiedy producenci zaczęli eksperymentować z alternatywami dla tradycyjnego zbrojenia stalowego. Cel był prosty: znaleźć rozwiązanie problemu korozji, który nękał stalowe pręty zbrojeniowe, szczególnie w regionach przybrzeżnych lub obszarach o wysokiej zawartości soli.

Globalna adopcja i przejście na FRP

Zastosowanie FRP w budownictwie zyskuje coraz większą popularność na całym świecie, a powodów jest wiele:

Odporność na korozję: W przeciwieństwie do stali, pręty zbrojeniowe FRP są z natury odporne na korozję. Ta cecha wydłuża żywotność konstrukcji, szczególnie w środowiskach narażonych na zasolenie lub działanie substancji chemicznych.

Waga: Pręty zbrojeniowe FRP są znacznie lżejsze od prętów stalowych, co pozwala na redukcję kosztów transportu i ułatwia proces montażu.

Neutralność magnetyczna: W przypadku obiektów takich jak szpitale czy placówki naukowe, gdzie zakłócenia magnetyczne mogą stanowić problem, zastosowanie FRP okazuje się nieocenione.

Wiodące kraje, takie jak USA, Kanada, Japonia i kilka krajów europejskich, są liderami we wdrażaniu prętów zbrojeniowych FRP. Na przykład w USA, zastosowanie FRP W przypadku pomostów mostowych nastąpił przełom, szczególnie w obszarach przybrzeżnych. Tymczasem Japonia, narażona na aktywność sejsmiczną, dostrzegła korzyści z zastosowania elastycznych, a jednocześnie wytrzymałych prętów zbrojeniowych FRP w swoich konstrukcjach, co zwiększa odporność na trzęsienia ziemi.

Potęga produkcyjna: producenci prętów zbrojeniowych FRP i innowacje

Wzrost popytu na pręty zbrojeniowe FRP doprowadził do powstania wyspecjalizowanych firm Producenci prętów zbrojeniowych FRP którzy nieustannie wprowadzają innowacje. Podczas gdy podstawowa zasada polega na osadzaniu włókien w matrycy żywicznej, producenci badają różne kombinacje włókien, rodzaje żywic i metody produkcji, aby zwiększyć wytrzymałość i elastyczność produktu końcowego.

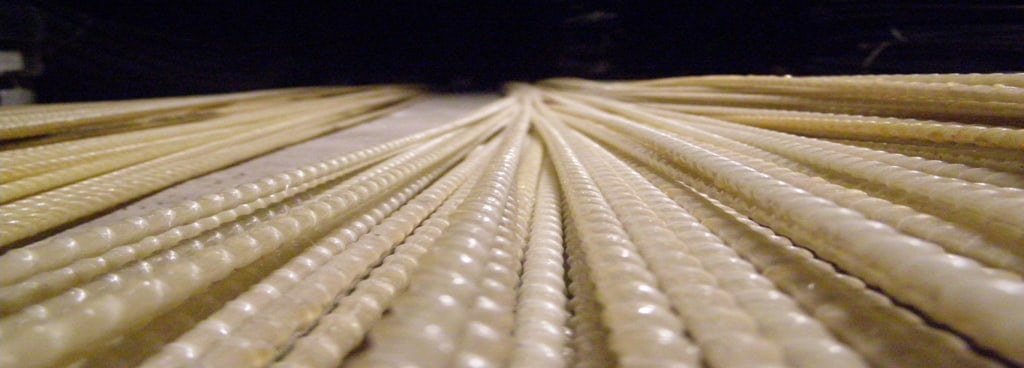

Proces produkcji prętów zbrojeniowych jest skomplikowany. Ciągłe włókna są przeciągane przez kąpiel żywiczną, co zapewnia ich dokładne pokrycie. Następnie są przepuszczane przez matrycę kształtującą i utwardzane, albo za pomocą ciepła, albo światła ultrafioletowego, co powoduje zestalenie żywicy i formowanie prętów zbrojeniowych.

Wielu wiodących producentów prętów zbrojeniowych FRP koncentruje się również na zrównoważonym rozwoju, wykorzystując żywice nadające się do recyklingu oraz włókna zrównoważone, aby zmniejszyć wpływ prętów kompozytowych na środowisko.

Dowiedz się więcej: Wpływ na środowisko FRP

FRP kontra stal: analiza porównawcza

Chociaż pręty zbrojeniowe FRP mają wiele zalet, ważne jest zrozumienie niuansów różnic między nimi a tradycyjnymi prętami stalowymi:

Wytrzymałość na rozciąganie:Pręty zbrojeniowe FRP wyróżniają się wytrzymałością na rozciąganie, często przewyższając stal. Mogą jednak mieć niższy moduł sprężystości, co oznacza, że mogą być bardziej elastyczne.

Przewodność cieplna: Pręty kompozytowe mają niższą przewodność cieplną niż stal, dzięki czemu nadają się do stosowania w regionach, w których występują ekstremalne wahania temperatury.

Koszt: Początkowo pręty zbrojeniowe FRP mogą wydawać się droższe od stali. Jednak biorąc pod uwagę wydłużoną żywotność konstrukcji i obniżone koszty konserwacji, długoterminowe korzyści ekonomiczne FRP stają się oczywiste.

- Pręty zbrojeniowe FRP kontra pręty zbrojeniowe stalowe

- Pręty zbrojeniowe GFRP kontra stal: koszty, wytrzymałość i długoterminowe korzyści w nowoczesnym budownictwie

- Pręty zbrojeniowe GFRP kontra pręty zbrojeniowe stalowe: porównanie techniczne

Droga przed nami: przyszłość prętów zbrojeniowych kompozytowych

Globalne doświadczenia z prętami zbrojeniowymi FRP wskazują na obiecującą przyszłość. W miarę jak coraz więcej profesjonalistów z branży budowlanej poznaje jego zalety, a producenci prętów zbrojeniowych FRP nadal wprowadzają innowacje, wykorzystanie FRP w budownictwie prawdopodobnie wzrośnie.

Co więcej, w miarę jak rosną globalne wymagania infrastrukturalne i priorytetem stają się względy środowiskowe, zrównoważony i długotrwały charakter prętów zbrojeniowych kompozytowych sprawia, że są one materiał wzmacniający przyszłości.

Wniosek

Ten światowe doświadczenie z prętami zbrojeniowymi FRP odzwierciedla szerszy trend w budownictwie: przejście na materiały, które są nie tylko mocne i trwałe, ale także przyjazne dla środowiska i opłacalne w dłuższej perspektywie. W miarę postępu technologii i stawania się coraz bardziej widocznych korzyści z FRP możemy spodziewać się wzrostu jego znaczenia w światowym budownictwie.

Poprzez eksplorację historii, Procesy produkcyjnei globalnym wdrażaniu prętów zbrojeniowych FRP, oczywiste jest, że przyszłość wzmocnień budowlanych leży w tych innowacyjnych materiałach kompozytowych.