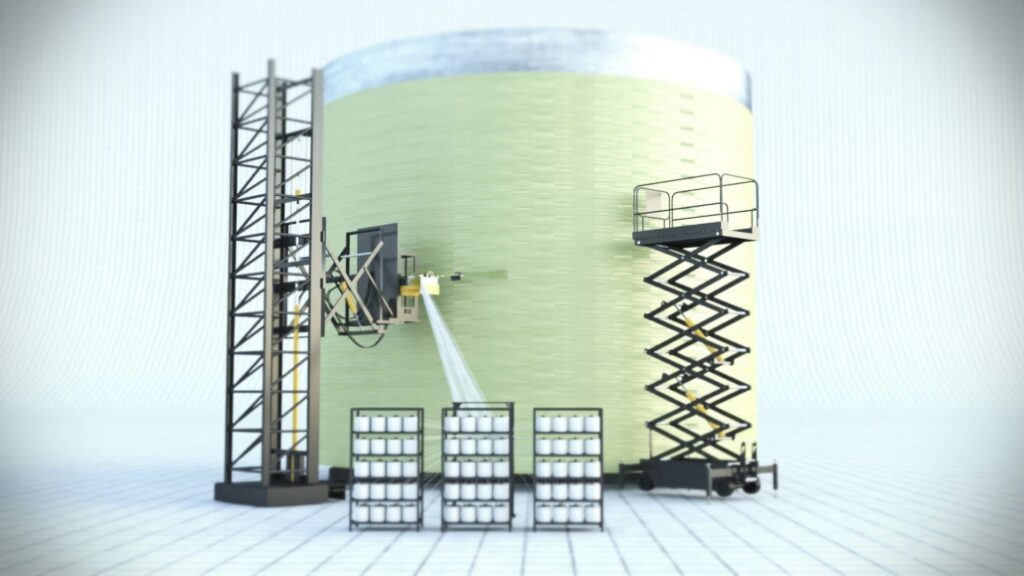

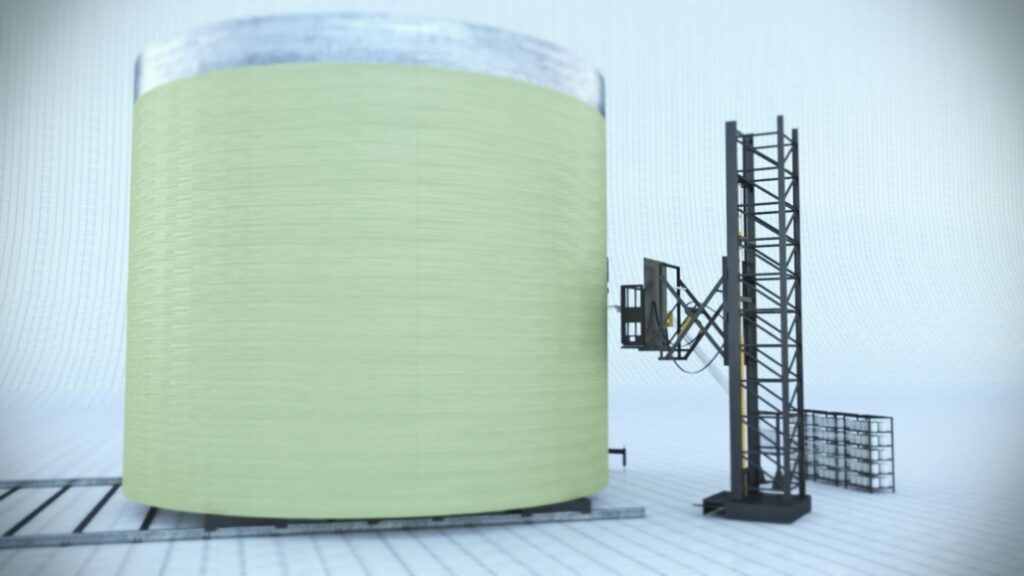

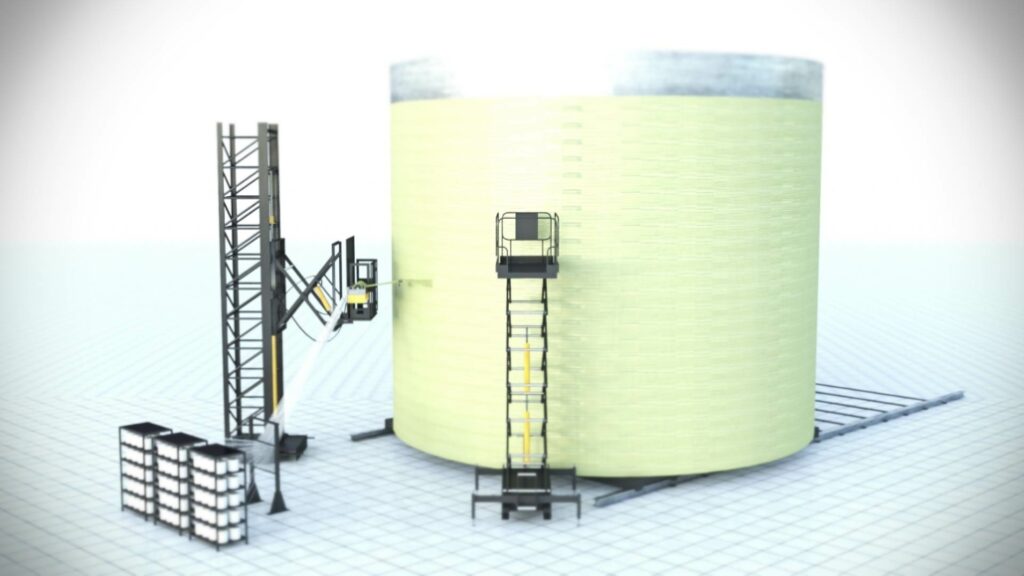

Composite-Tech porta l'industria dei compositi a un livello mai visto prima con l'introduzione della nostra nuova linea di produzione di silos in FRP. I silos in composito di fibra di vetro vantano numerosi vantaggi rispetto ai tradizionali silos in metallo per impieghi gravosi, elevando il settore a un nuovo livello di sostenibilità ed efficacia.

Le linee di produzione di silos vetroresina di Composite-Tech offrono:

- Automazione completa

- Ampia gamma di tipologie di silos e applicazioni (vedi sotto)

- Tecnologia di produzione conveniente

- Processo produttivo sostenibile

I tipi di silos in fibra di vetro di Composite-Tech vengono utilizzati in:

- Industria petrolifera e del gas

- Industria agricola (stoccaggio dei cereali e altro)

- Stoccaggio dell'acqua

- Rifiuti e acqua di mare

- Stoccaggio di prodotti chimici

- Basso ossigeno / Alta pressione

Possibili forme di silos in FRP realizzate con la nostra linea di produzione:

- Silo standard

- Fondo piatto

- Tramoggia (silo a fondo imbuto)

- Caricamento camion/treno

- Dimensione variabile

Le nostre attrezzature sono progettate per essere affidabili, altamente produttive e uniche nella tecnologia che utilizziamo! Tutti i nostri sviluppi e innovazioni sono brevettati, il che garantisce non solo un'elevata efficacia del tuo investimento, ma anche un mercato libero dalla concorrenza. Inoltre, per garantire l'affidabilità di tutti i moduli della linea di produzione utilizziamo solo quei componenti che hanno superato i nostri rigorosi test e valutazioni delle prestazioni.

Grazie all'acquisizione di attrezzature per la produzione di silos in GFRP Composite-Tech, i nostri clienti in Italia possono ottenere anche i seguenti risultati:

- Calcoli legati alla produzione di un prodotto finale specifico

- I nostri specialisti eseguono l'installazione delle apparecchiature e svolgono lavori di messa in servizio

- Formazione del personale

- Consulenza continua da parte dei nostri esperti tecnici

Caratteristiche tecniche

Caratteristiche tecniche della linea di produzione dei silos in GFRP

| Scopo: | produzione di silos in fibra di vetro |

| voltaggio: | 380V / 50Hz |

| Energia: | 30 kW |

| Prestazioni della linea: | Dipende dal prodotto finale |

| Lunghezza dell'attrezzatura: | 12 metri |

| Larghezza: | 2,5 metri |

| Altezza: | 2,8 metri |

Vantaggi dei silos in FRP rispetto ai silos utilizzati in modo convenzionale:

- Resistenza alla corrosione – I silos in GFRP sono resistenti alla corrosione derivante dall’acqua di mare, da sostanze chimiche, petrolio, gas, calore, raggi UV e condizioni ambientali estreme.

- Risparmio di spazio – Per quanto riguarda lo stoccaggio di cereali agricoli, i magazzini rappresentano un'altra opzione. Tuttavia, è in questo caso che i silos consentono di risparmiare molto più spazio grazie alla loro posizione verticale.

- Zero sprechi di prodotto immagazzinato – La disposizione verticale dei silos facilita lo scarico del prodotto immagazzinato e non si verificano sprechi di prodotto dovuti alla mancanza di scomparti interni, ripiani, ecc.

- Temperatura interna, umidità e pressione – I silos in FRP sono costruiti con un sistema di gestione interno ben definito. Di conseguenza, tutti i requisiti legati allo stoccaggio in ambito agricolo e petrolifero e del gas vengono non solo rispettati, ma anche semplificati, grazie alle migliori caratteristiche primarie del comportamento dei silos in GFRP.

- Sostenibilità – Il prodotto finale delle nostre linee di produzione di silos compositi contribuisce alla sostenibilità nell'edilizia, orientando il settore verso soluzioni più ecologiche.

- Durata / Leggerezza – L'elevata resistenza rende i silos in fibra di vetro resistenti alle vibrazioni e ad altre forze interne ed esterne applicate al silos. I silos in GFRP sono leggeri rispetto ai silos in ghisa sferoidale, acciaio dolce e HDPE. La leggerezza garantisce facilità di movimentazione, trasporto e installazione. Queste qualità rendono i silos in FRP molto più durevoli, affidabili ed economici rispetto ai silos convenzionali.

- Resistenza all'infiammazione – A differenza delle loro controparti in ferro, i silos in vetroresina non esplodono e non prendono né sostengono il fuoco.

- Opzioni di personalizzazione – Adatto a praticamente ogni possibile esigenza industriale.

- Mancanza di contaminazione – I silos in FRP non arrugginiscono e quindi non hanno alcun effetto sui liquidi immagazzinati, indipendentemente dal fatto che si tratti di acqua, gas liquido o sostanze chimiche.

- Manutenzione e riparazione minime – La lunga aspettativa di vita elimina i costi aggiuntivi legati alle riparazioni.

- Resistenza alla pressione – L’elevata rigidità e l’elevata capacità di carico compressivo dei silos in FRP impediscono le fluttuazioni della pressione di scoppio.

- Efficienza idraulica– I silos in GFRP hanno una superficie interna liscia che favorisce eccellenti caratteristiche idrauliche, un'elevata capacità di flusso e un basso attrito.

Produzione chiavi in mano di barre d'armatura in GFRP in Italia!

Confrontando il prezzo di vendita delle barre d'armatura in GFRP con quello delle barre d'armatura in acciaio, si ottiene un margine di profitto di oltre 120%!

Ottieni la tua linea di produzione in soli 2 mesi dall'ordine e rientra del tuo investimento in soli 3 mesi dall'avvio della produzione.

Applicazione del silo FRP

I silos in FRP sono comunemente utilizzati nelle applicazioni fuori terra in cui sono essenziali elevata resistenza, efficienza idraulica ed elevata resistenza.