La rivoluzione nel rinforzo

Per oltre un secolo, l'acciaio è stato la spina dorsale delle infrastrutture moderne. Tuttavia, le sfide legate alla corrosione, al peso e alla sostenibilità stanno costringendo gli ingegneri a ripensare il futuro delle armature.

Entra GFRP (polimero rinforzato con fibra di vetro) — un materiale più leggero, più resistente, non corrosivo e 100% resistente alla degradazione chimica.

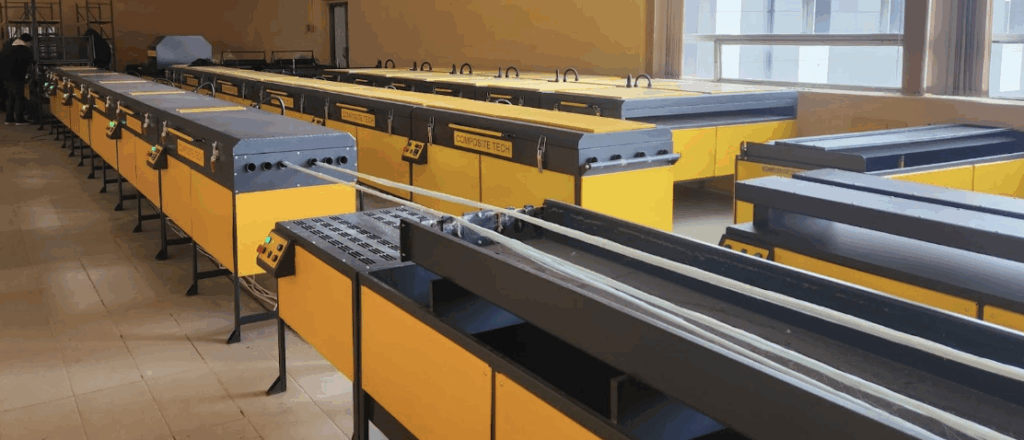

Al centro di questo cambiamento globale si trova Composite-Tech, produttore europeo di attrezzature avanzate per barre d'armatura in FRP, reti ed elementi piegati, progettate, testate e realizzate per soddisfare i più elevati standard mondiali.

"La nostra missione è semplice: costruire il futuro del rinforzo. Un rinforzo che duri più a lungo, pesi meno e protegga il pianeta."

— Anton Ocunev, CEO di Composite-Tech

Dall'acciaio al rinforzo intelligente

La sola corrosione costa all'economia statunitense oltre $22 miliardi all'anno (Dipartimento dei trasporti degli Stati Uniti).

In ambienti aggressivi come le zone costiere e i ponti, le barre d'armatura in acciaio tradizionali perdono fino a 40% della loro resistenza alla trazione entro 10 anni.

FRP, d'altra parte:

- Ha un resistenza alla trazione 2,5 volte superiore che l'acciaio

- pesa 4 volte meno

- È completely immune alla corrosione

- Ha un durata di servizio di 80-100 anni senza degrado

Ecco perché i principali progetti infrastrutturali, dai ponti in Florida ai tunnel in California, sono ora progettati con Rinforzo FRP in conformità con ACI 440.11-22 E ASTM D7957.

Precisione ingegneristica Made in Europe

A differenza delle attrezzature manuali a basso costo, Macchine Composite-Tech sono progettati con Precisione ingegneristica europea E controllo di processo completamente automatizzato.

Ogni sistema garantisce:

- Allineamento perfetto delle fibre

- Impregnazione uniforme della resina

- Temperatura di polimerizzazione costante

- Calibrazione automatica del diametro

Questa precisione è ciò che garantisce che ogni barre d'armatura in FRP prodotto su una linea Composite-Tech soddisfa i i più rigorosi standard di prestazioni meccaniche richiesto nel mercato statunitense.

Ricerca, test e certificazione

Ogni nuova linea sviluppata da Composite-Tech passa attraverso un ciclo completo di test:

- Test di resistenza termica (da -40°C a +200°C)

- Verifica della resistenza a trazione e flessione

- Analisi dell'esposizione chimica e UV

La collaborazione in corso di Composite-Tech con FRP Institute (USA) garantisce che tutte le apparecchiature e i parametri di produzione rimangano allineati con ultimi standard ACI e ASTM, creando un processo di qualità trasparente e tracciabile.

La sostenibilità come valore fondamentale

Oltre alle prestazioni, la sostenibilità è al centro della filosofia di Composite-Tech.

Grazie alla sostituzione dell'acciaio con FRP non corrosivo, l'azienda contribuisce a ridurre:

- emissioni di CO₂ dalla produzione di acciaio

- Costi di manutenzione e sostituzione di 70%

- Rifiuti di cemento dal deterioramento delle infrastrutture

La FRP non è solo un'alternativa: è una necessità ambientale nel XXI secolo.

Portata globale, impatto locale

Le macchine Composite-Tech sono ora operative in oltre 20 paesi, tra cui:

🇺🇸 U.S.A.🇮🇳 India 🇿🇦 Sudafrica 🇷🇴 Romania 🇪🇸 Spagna 🇨🇦 Canada

Dalle piccole startup locali ai grandi fornitori di costruzioni, i clienti scelgono Composite-Tech perché ogni macchina è:

- Pronto per la conformità ACI/ASTM

- Costruito per una produzione continua 24 ore su 24, 7 giorni su 7

- Supportato da installazione e formazione in loco

Il futuro: grafene e compositi intelligenti

Il team di ricerca e sviluppo di Composite-Tech sta attualmente integrando grafene nanotecnologia in barre d'armatura in GFRP, migliorandone la conduttività, la resistenza e la resistenza alle microfessure.

Questa nuova generazione di rinforzi ridefinirà presto il modo in cui gli ingegneri progettano strutture di lunga durata per ponti, autostrade e infrastrutture energetiche.

Conclusione: progettare il futuro

Composite-Tech combina Eccellenza manifatturiera europea, precisione scientifica, E una visione per l'edilizia sostenibile.

Ogni macchina è il frutto di decenni di ricerca e di una missione chiara: aiutare le aziende di tutto il mondo a costruire sistemi più forti, più intelligenti e più ecologici.

Pronti a costruire la vostra fabbrica FRP?

Richiedi un'analisi personalizzata del ROI e scopri come Composite-Tech può aiutarti a lanciare la produzione entro 60 giorni.

Contatto il nostro team di ingegneria

Saperne di più:

- Composite-Tech e FRP Institute annunciano una partnership strategica per ridefinire gli standard globali nel settore del rinforzo FRP

- Perché Composite-Tech e FRP Institute stanno definendo gli standard globali per i compositi

- Redditività del settore della produzione di barre d'armatura e reti in GFRP negli Stati Uniti

- Composite-Tech: leader mondiale nella produzione di barre d'armatura, reti e materiali compositi in GFRP