Introduction : Un changement de paradigme dans le renforcement du béton

La construction moderne exige des matériaux non seulement solides et durables, mais aussi légers et résistants aux dégradations environnementales. L'une des innovations les plus révolutionnaires dans ce domaine est l'intégration du graphène dans les barres d'armature en polymère renforcé de fibres de verre (PRFV). En combinant les propriétés mécaniques et chimiques exceptionnelles du graphène avec celles du PRFV traditionnel, nous obtenons une nouvelle classe de renfort qui surpasse l'acier et le PRFV standard dans pratiquement tous les domaines critiques.

Cet article explore :

- Pourquoi le graphène est un matériau révolutionnaire pour l'industrie de la construction

- Performances techniques des barres d'armature composites enrichies en graphène

- Analyse comparative avec l'acier et le PRFV conventionnel

- Avantages économiques et structurels

- Comment Composite-Tech permet la fabrication évolutive de barres d'armature à base de graphène

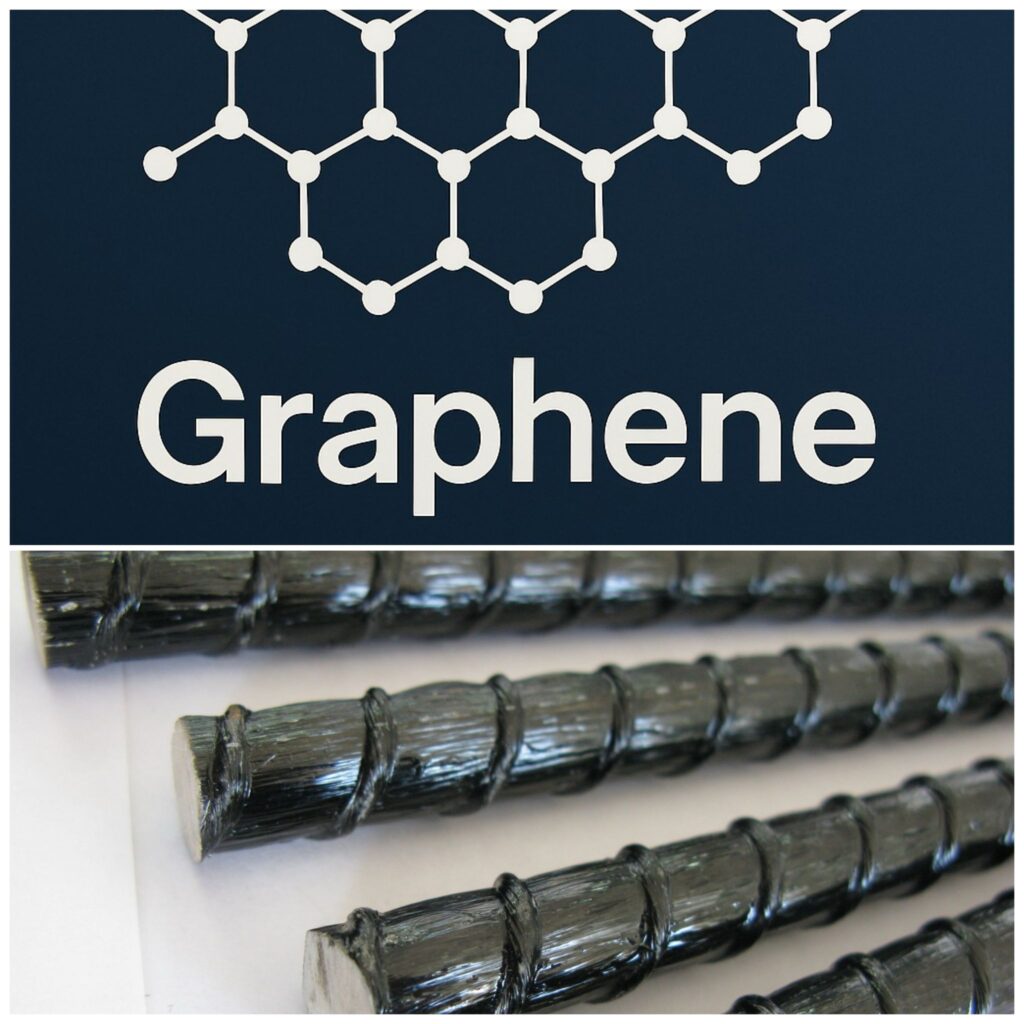

Qu’est-ce que le graphène et pourquoi est-ce important ?

graphène Il s'agit d'une couche unique d'atomes de carbone disposés selon un réseau hexagonal bidimensionnel. Il est reconnu comme l'un des matériaux les plus résistants et les plus conducteurs jamais découverts.

Selon l'Université de Manchester, le graphène présente :

| Propriété | Valeur |

| Résistance à la traction | Jusqu'à 130 GPa (Acier : 0,4–2,0 GPa) |

| Module de Young | ~1 TPa |

| Conductivité thermique | Jusqu'à 5000 W/(m·K) |

| Conductivité électrique | ~13× plus élevé que le cuivre |

| Épaisseur | 0,345 nm |

Lorsqu'il est dispersé dans la matrice polymère du GFRP, le graphène agit comme un renfort à l'échelle nanométrique, améliorant le transfert de charge entre les fibres et la matrice, réduisant les microfissures et améliorant l'intégrité structurelle globale.

Analyse comparative : PRFV vs PRFV enrichi en graphène vs barres d'armature en acier

| Paramètre | PRFV standard | Graphène GFRP | Barres d'armature en acier A400 |

| Résistance à la traction (MPa) | 1000–1400 | 1800–2300 | 390–490 |

| Module d'élasticité (GPa) | 45–55 | 60–75 | 200 |

| Densité (g/cm³) | 1,9–2,1 | 2,0–2,2 | 7.85 |

| Résistance à la corrosion | Haut | Très élevé | Faible |

| Conductivité électrique | Zéro | Modéré (réglable) | Haut |

| Résistance aux alcalis/sulfates | Haut | Maximum | Moyen |

| Durée de vie du béton | 80 à 100 ans | 100–120 ans | 30 à 50 ans |

Même 0,1 à 0,31 TP5T de graphène en poids peut augmenter la résistance du GFRP jusqu'à 601 TP5T et améliorer la rigidité de 20 à 301 TP5T.

Principaux avantages des barres d'armature en PRFV enrichies en graphène

- Rapport résistance/poids supérieur

Les barres d'armature en graphène GFRP offrent une résistance spécifique 5 à 7 fois supérieure à celle de l'acier tout en étant 4 fois plus légères, ce qui réduit considérablement les coûts de transport et d'installation.

- Durabilité inégalée

Dans les environnements difficiles (marins, chimiques, souterrains), l’inertie chimique du graphène et de la fibre de verre assure une résistance exceptionnelle à la corrosion, aux alcalis, aux sulfates et à l’humidité.

- Liaison améliorée avec le béton

Le graphène améliore la nano-interaction entre la surface des barres d'armature et la pâte de ciment, augmentant la force de liaison et réduisant la propagation des microfissures.

- Transparence électromagnétique

Contrairement à l'acier, le GFRP avec graphène n'interfère pas avec les signaux RF ou les réseaux de capteurs, ce qui le rend idéal pour les bâtiments intelligents, les infrastructures avec capteurs IoT et les environnements sensibles aux champs électromagnétiques.

- Stabilité thermique et dynamique

La structure hybride résiste aux fluctuations de température, à l'exposition aux UV, aux cycles de gel-dégel et aux vibrations mécaniques, surpassant le renforcement traditionnel en termes de résilience à long terme.

Efficacité économique et environnementale

Bien que le graphène soit toujours un nanomatériau haut de gamme (son prix actuel est compris entre 50 et 100 € le gramme), son dosage requis est extrêmement faible.

Calcul de l'étude de cas :

- Barres d'armature standard en PRFV Ø12 mm: ~0,45 €/mois

- Barres d'armature en graphène GFRP (ajout de 0,2%): ~0,55 €/mois

- Augmentation de la force: ~+50%

- Durée de vie: +30–50 ans

- Économies:Des dizaines de milliers d'euros par projet en maintenance réduite, en réparation de la corrosion et en remplacement des armatures.

Dans l’analyse du coût du cycle de vie, les barres d’armature en graphène surpassent toutes les autres options, tant sur le plan économique que technique.

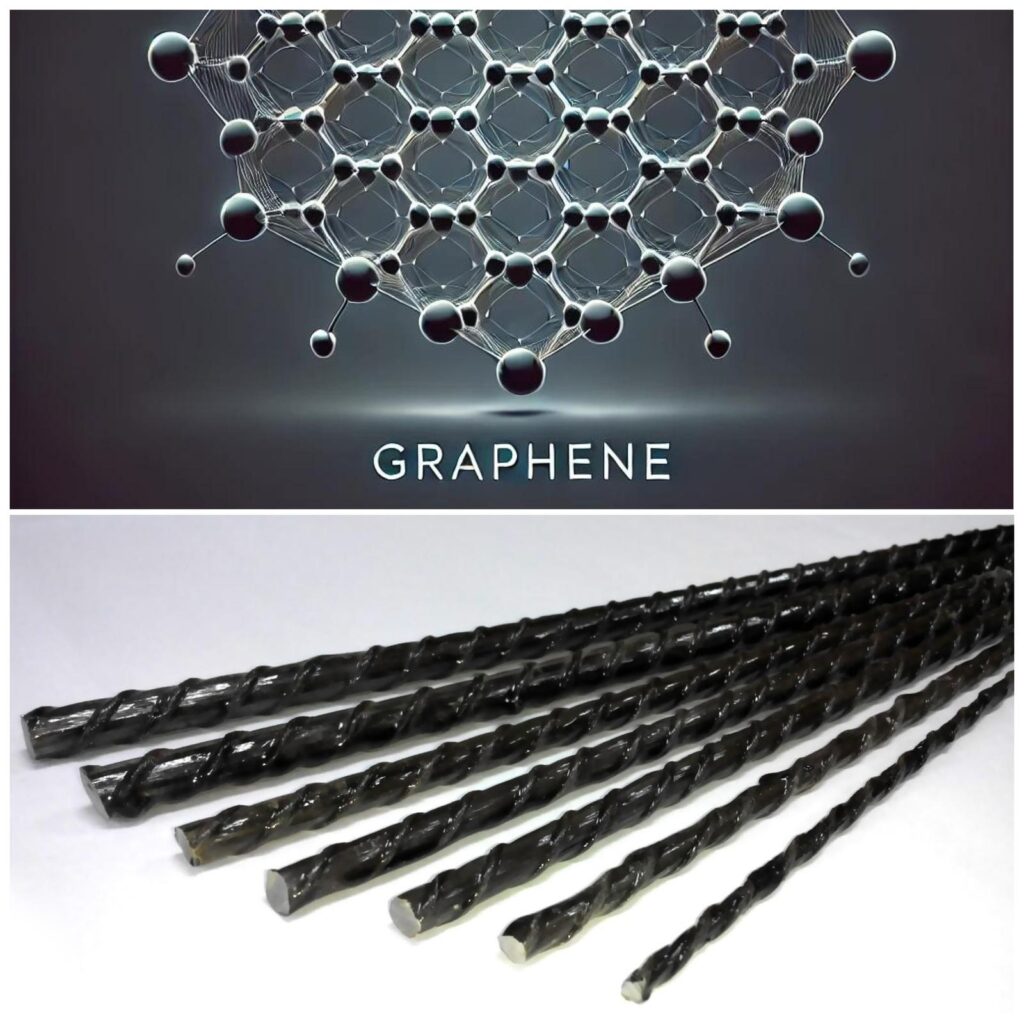

Composite-Tech : ouvrir la voie à l'avenir des composites renforcés

Chez Composite-Tech, nous proposons des solutions avancées lignes de fabrication de barres d'armature en PRFV, spécialement conçu pour l'intégration avec des nanomatériaux à base de graphène.

Nos systèmes propriétaires comprennent :

- Dosage précis du graphène dans le système d'alimentation en résine

- Homogénéisation à l'échelle nanométrique pour éviter l'agglomération

- Contrôle thermique et rhéologique optimisé pour une qualité constante

- Lignes modulaires capable de produire des treillis, des barres pliées, des hélicoïdaux et des profils personnalisés

Nous utilisons des bains d'imprégnation et des modules de chauffage personnalisés conçus pour répondre aux défis de viscosité et de dispersion du graphène, garantissant des performances optimales.

Applications des barres d'armature renforcées au graphène

- Ponts et structures maritimes exposé à des éléments agressifs

- Infrastructures souterraines: tunnels, barrages, stations de métro

- Sols industriels et usines chimiques nécessitant une durabilité extrême

- Villes intelligentes et infrastructures intelligentes:renforcement transparent au signal

- Construction de grande hauteur et monolithique, en particulier dans les zones sismiques

Conclusion : Construire demain avec le graphène

L'intégration du graphène dans les barres d'armature en PRFV n'est pas seulement une innovation, c'est une évolution matérielle. Elle établit une nouvelle norme en matière de performances mécaniques, de résistance environnementale et de longévité. Grâce aux équipements de pointe de Composite-Tech, les fabricants peuvent désormais produire efficacement ces barres d'armature de nouvelle génération et accélérer la transition vers des infrastructures plus intelligentes et plus résilientes.

Prêt à innover votre production ?

Visitez Composite-Tech pour découvrir comment nous pouvons vous aider à construire l’avenir — plus fort, plus léger et plus intelligent.