Композитните анкери, изработени от полимер, подсилен със стъклени влакна (GFRP), и полимер, подсилен с базалтови влакна (BFRP), представляват значителен напредък в технологията за структурно армиране. Тези иновативни системи предоставят основни решения за постигане на висока якост на опън, подобрена устойчивост на корозия и устойчиво развитие в гражданското и геотехническото инженерство.

Съдържание

Какво представляват композитните анкери?

Композитните анкери се произвеждат с помощта на непрекъснати стъклени или базалтови влакна, вградени в полимерна матрица, обикновено епоксидна или винилестерна смола. Базалтовите влакна, получени от вулканична скала, предлагат превъзходна химическа стабилност и термична устойчивост, докато стъклените влакна представляват рентабилна алтернатива с отлични механични свойства. Тези анкери се произвеждат с помощта на техники на пултрузия и формоване, осигуряващи еднакви напречни сечения и постоянни механични характеристики.

Предимства на GFRP/BFRP анкерите пред стоманата

Композитните анкери показват редица предимства в сравнение с традиционната стоманена армировка:

- Високо съотношение на якост към тегло:

BFRP анкерите постигат якост на опън между 1000 и 1200 MPa с плътност от приблизително 2,6 g/cm³, докато GFRP анкерите достигат 600–800 MPa при подобна плътност. Тази висока специфична якост позволява значително намаляване на теглото на конструкциите, което улеснява по-лесното боравене и монтаж. - Превъзходна устойчивост на корозия:

Както GFRP, така и BFRP са по своята същност устойчиви на корозия, причинена от влага, хлориди и химическо въздействие. За разлика от стоманата, тези материали запазват своята цялост в тежки условия, включително морски и промишлени приложения. - Термична и електрическа изолация:

И двата вида композитни анкери са непроводящи и проявяват ниска топлопроводимост, което ги прави особено полезни в среди с високо напрежение и зони със значителни температурни колебания. - Подобрено сцепление с бетон:

Текстурираната повърхност и химичният афинитет на композитните влакна водят до отлична адхезия към бетона, което води до подобрено пренасяне на натоварването и намален риск от подхлъзване под напрежение. - Екологична устойчивост:

- Производството както на GFRP, така и на BFRP анкери води до значително по-ниски емисии на CO₂ в сравнение с производството на стомана. Освен това, тези материали са нетоксични и безопасни за рециклиране или обезвреждане в края на жизнения цикъл на конструкцията.

Сравняване на GFRP и BFRP анкери

Въпреки че и двата материала имат общи предимства, те показват и специфични разлики в производителността:

- Механична якост и твърдост:

BFRP анкерите обикновено осигуряват по-висока якост на опън и твърдост от GFRP, предлагайки подобрена носеща способност и структурна цялост. - Термична производителност:

BFRP поддържа стабилност при температури до приблизително 750 °C, докато GFRP обикновено издържа до 500 °C. Това свойство е особено ценно в пожароопасни или високотемпературни среди. - Химична стабилност:

BFRP анкерите демонстрират превъзходна устойчивост на химическо въздействие в киселинни и алкални среди, което ги прави предпочитани в силно агресивни условия. - Икономически съображения:

GFRP анкерите са по-рентабилни при първоначалната покупка, докато BFRP анкерите често осигуряват превъзходна дългосрочна издръжливост, което води до по-ниски разходи за поддръжка през целия живот на конструкцията.

Приложения на композитни анкери

Композитните анкери се използват в широк спектър от инженерни дисциплини:

- Геотехническо инженерство:

Ефективен за стабилизиране на склонове, закрепване на почвата и подпорни конструкции, особено в райони, предразположени към свлачища и сеизмични райони. - Тунелиране и минно дело:

Използва се широко в системи за скални болтове и като армировка за облицовки от пръскан бетон, където високата якост на опън и устойчивост на корозия са от решаващо значение. - Гражданско инженерство:

Прилага се в мостови настилки, кейови стени, подпорни стени и армировки на основи, осигурявайки дълготрайни решения дори при тежки условия на околната среда. - Морски конструкции:

Подходящ за употреба в офшорни платформи и пристанищни съоръжения, където устойчивостта на солена вода и агресивни химикали е от съществено значение. - Специални инсталации:

Използват се във високоволтови зони, ЯМР съоръжения и telecommunications инфраструктура поради непроводимите им свойства.

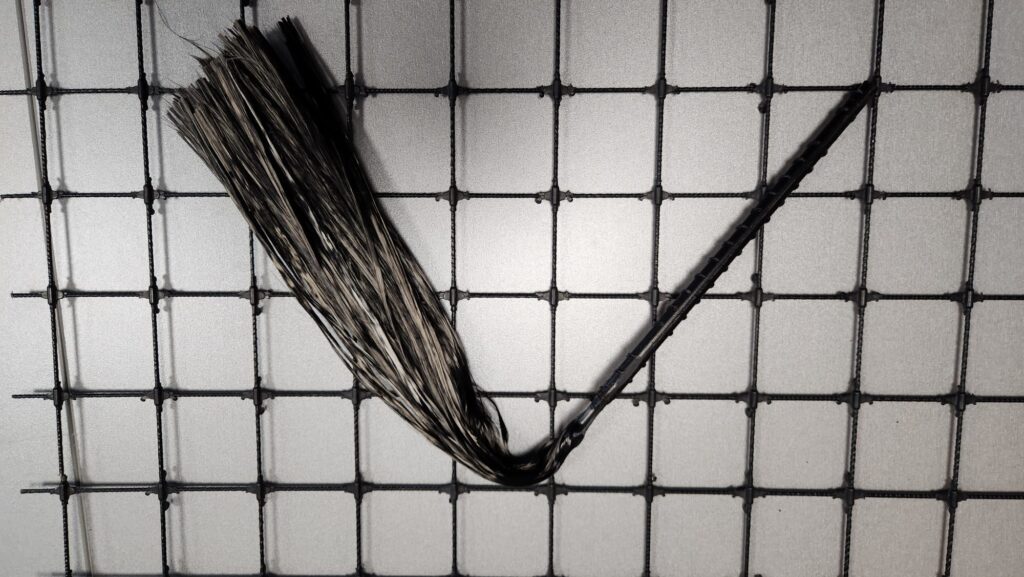

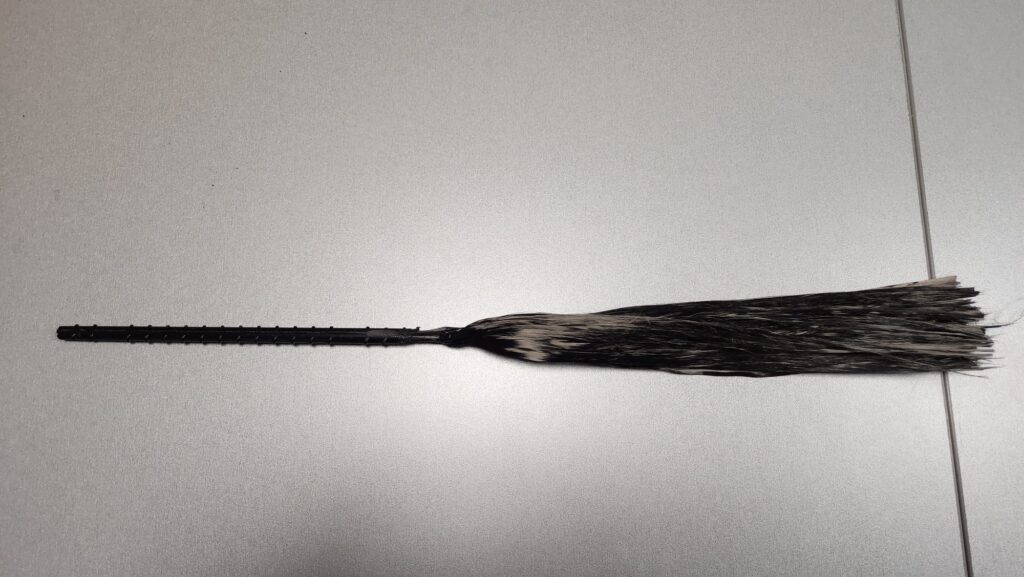

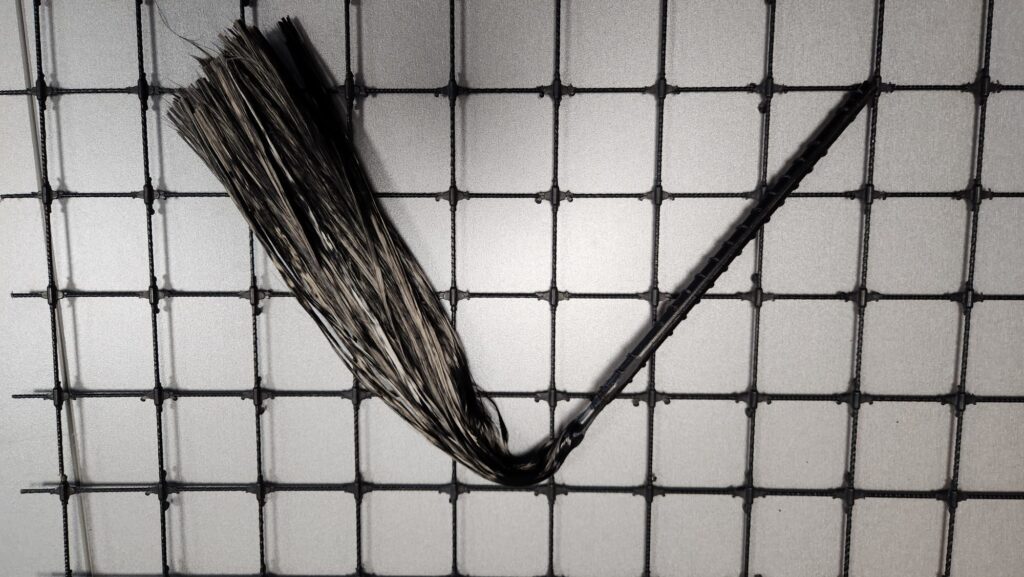

Методология на монтаж и анкери с „космата глава“

Монтирането на композитни анкери следва строг процес, за да се осигури оптимална производителност:

- Пробиване: Отворите се подготвят с подходящ диаметър и дълбочина, обикновено с 2–4 мм по-големи от диаметъра на анкера, за да се осигури залепващото съединение.

- Почистване: Отстраняването на прах и отломки от пробитите отвори осигурява максимална ефективност на залепването.

- Нанасяне на лепило: В отвора се инжектира подходяща полимерна смола или циментово лепило, осигурявайки пълно покритие.

- Вмъкване на котва: Анкерът се поставя с въртеливо движение, за да се осигури равномерно разпределение на лепилото и да се елиминират въздушните джобове.

- Втвърдяване: Лепилото се оставя да се втвърди напълно, преди да се приложи каквото и да е натоварване.

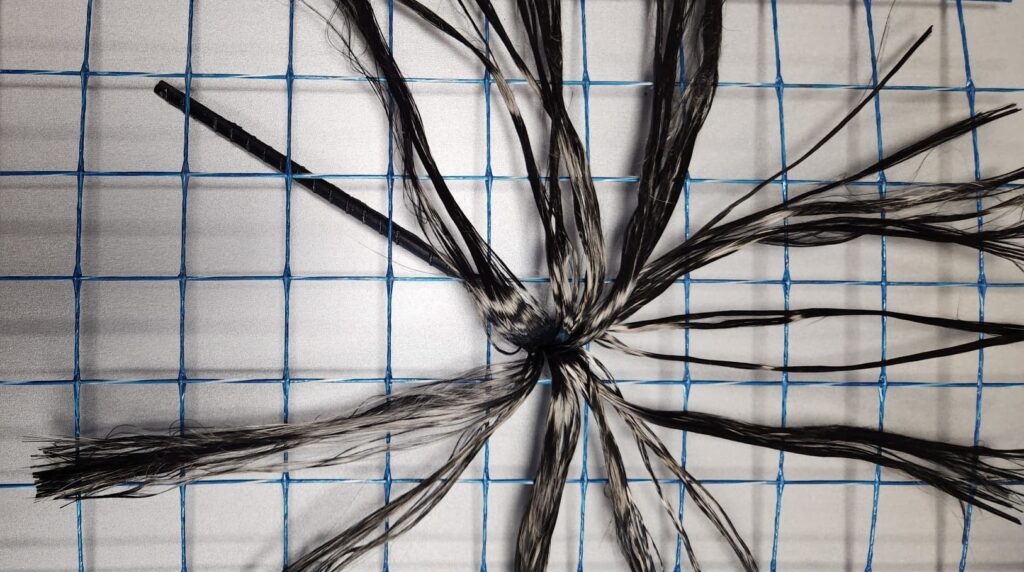

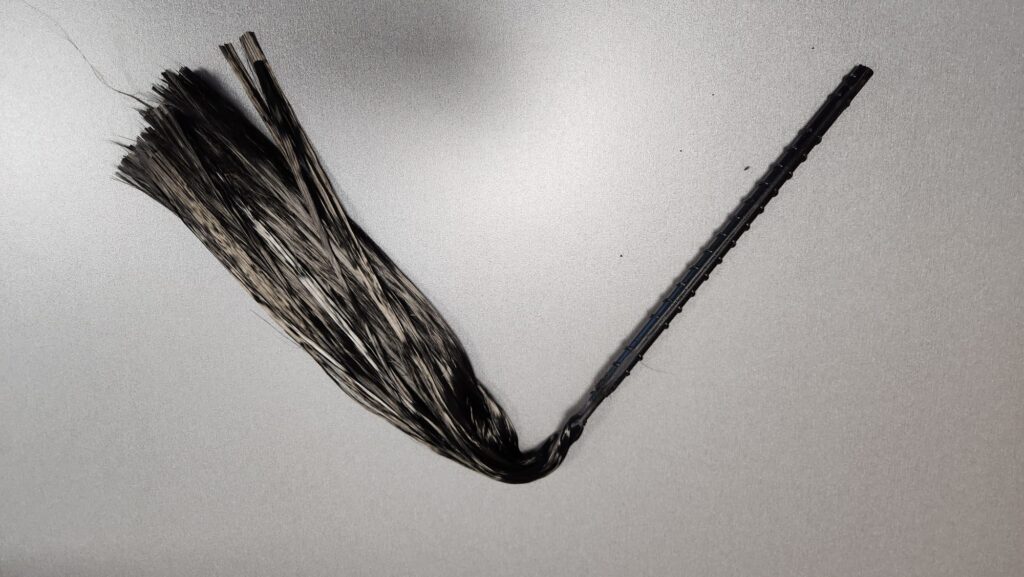

- Лечение на фиброопашката: Характерната „влакнеста глава“ на влакната може да бъде разперена, за да се подобри механичното сцепление и да се подобри пренасянето на натоварването върху околния бетон. Тази секция може да бъде импрегнирана с допълнителна смола или циментова суспензия, за да се образува интегрирана анкерна глава.

Издръжливост и дългосрочна производителност

Композитните анкери демонстрират забележителна издръжливост при различни условия на околната среда:

- Химическа и екологична устойчивост:

Както GFRP, така и BFRP анкерите запазват своята якост на опън и целостта на свързването за продължителни периоди, дори в агресивна морска и промишлена среда. - Стабилност при замръзване и размразяване:

Обширните тестове показват, че композитните анкери проявяват отлична устойчивост на цикли на замръзване-размразяване, с незначителна загуба на механични свойства. - Неразрушителен контрол (NDT):

Усъвършенстваните методи за тестване, включително ултразвукови и термографски техники, осигуряват контрол на качеството по време на монтажа и през целия експлоатационен живот на анкера.

Икономически и екологични съображения

Използването на композитни анкери води до значителни икономически и екологични ползи:

- Намалена поддръжка:

Поради устойчивостта си на корозия, композитните анкери изискват минимална поддръжка в сравнение със стоманените, което намалява дългосрочните експлоатационни разходи. - Устойчиво развитие:

Производството на GFRP и BFRP анкери генерира по-малко емисии на парникови газове, което допринася за по-устойчиви строителни практики. - Безопасно изхвърляне:

За разлика от някои опасни материали, и двата вида влакна са нетоксични и безопасни за изхвърляне или рециклиране в края на експлоатационния им живот.

Заключение

Композитните анкери, изработени от GFRP и BFRP материали, представляват трансформативен напредък в технологията за структурно армиране. Тяхната комбинация от висока якост на опън, устойчивост на корозия, лека конструкция и екологична устойчивост ги позиционира като идеално решение за съвременните инфраструктурни предизвикателства. Чрез интегрирането на тези иновативни материали, инженерите и дизайнерите могат да създават конструкции, които са не само по-надеждни, но и допринасят за устойчиво бъдеще.

Научете повече: