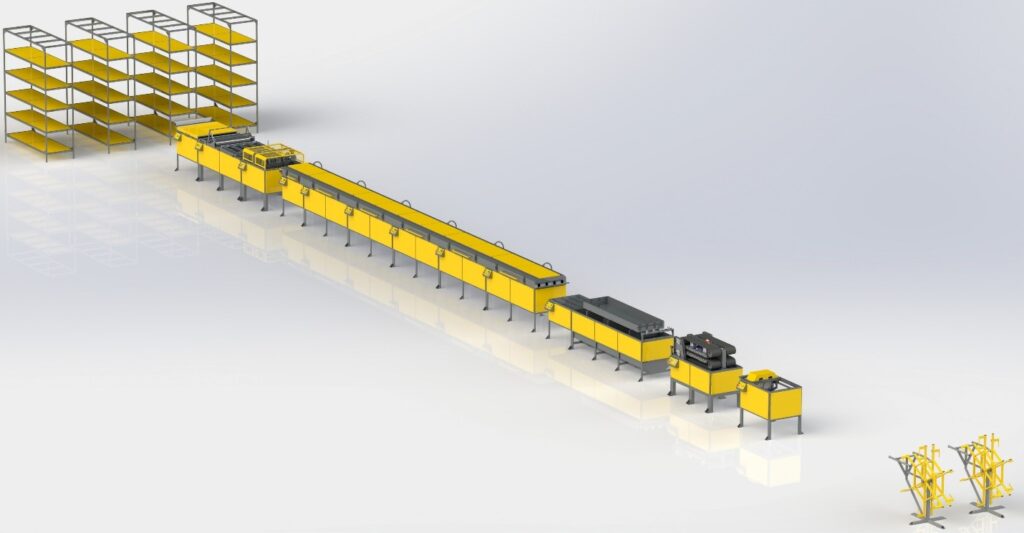

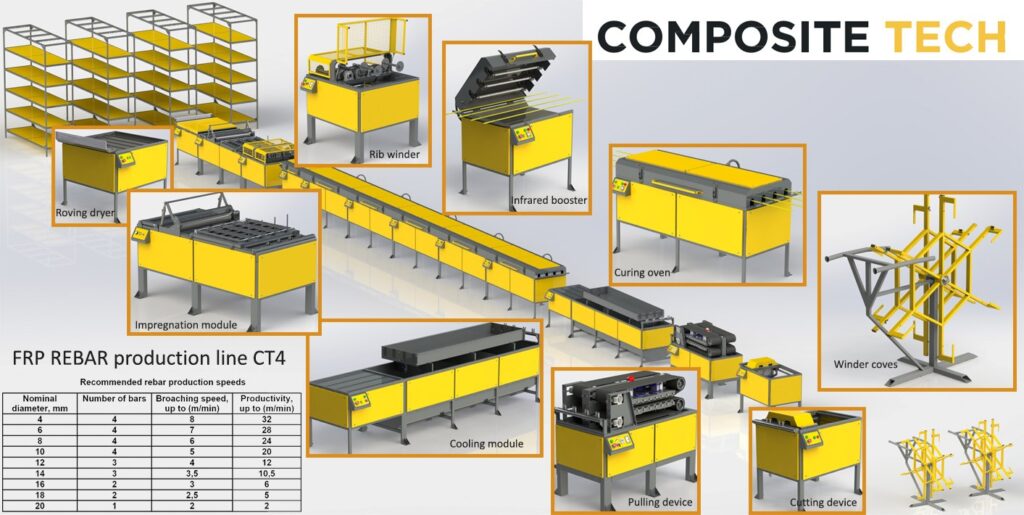

The CT4 machine is designed for the production of glass fiber reinforced polymer (GFRP) rebar with diameters ranging from 4 mm to 20 mm. It can simultaneously produce up to 4 rebar rods, ensuring high productivity and cost-efficiency. The machine comprises several key components, each performing a specific function in the production process.

Key Features of CT4

| Характеристика | Ценить |

|---|---|

| Rebar Diameters | 4 mm - 20 mm |

| Number of Rods | Up to 4 |

| Overall Productivity | Up to 32 m/min |

| Components | 12 main modules |

1. Крючок

- Функция: Holds spools of roving and creates initial tension in the threads using guide rings through which the threads pass.

2. Roving Dryer

- Функция: Aligns and dries the roving threads, ensuring even heat distribution and optimal moisture content for subsequent impregnation with polymer resin.

3. Модуль пропитки

- Функция: Impregnates the roving threads with resin and presses them to maintain crucial properties of the polymer binder (flow, cure rate, temperature) while reducing polymer consumption through a modern pressing system.

4. Rib Winder

- Функция: Winds periodic profiles (ribs) with precise winding steps for each rebar size, ensuring a strictly cylindrical rod shape and removing air from the impregnated rod.

5. Infrared Booster

- Функция: Accelerates the resin polymerization process.

6. Tunnel Kiln

- Функция: Used for resin polymerization, where the resin cures and the final GFRP rebar is formed.

7. Cooling Module

- Функция: Cools the GFRP rebar.

8. Pulling Device

- Функция: Pulls the GFRP rebar and determines the pulling speed.

9. Cutting Device

- Функция: Cuts the GFRP rebar to the desired length.

10. Winder Coves

- Функция: Lays the GFRP rebar into coils.

11. Automatic Coiler (Optional)

12. Device for Twisting Fiberglass Strands

- Функция: Forms ribbed thread by twisting roving threads.

Productivity

| Rebar Diameter (mm) | Number of Rods | Pulling Speed (m/min) | Производительность (м/мин) |

|---|---|---|---|

| 4 | 4 | 8 | 32 |

| 6 | 4 | 7 | 28 |

| 8 | 4 | 6 | 24 |

| 10 | 4 | 5 | 20 |

| 12 | 3 | 4 | 12 |

| 14 | 3 | 3.5 | 10.5 |

| 16 | 2 | 3 | 6 |

| 18 | 2 | 2.5 | 5 |

| 20 | 1 | 2 | 2 |

These data are approximate and depend on the characteristics of the resins used and environmental conditions.

Technical Specifications of CT4

| Параметр | Ценить |

|---|---|

| Power Supply | 380 В, 50 Гц |

| Power Consumption | 50 kW |

| Dimensions | 12000 x 2500 x 2500 mm |

| Масса | 5000 кг |

| Operating Temperature | 15-30°C |

Арматура GFRP представляет собой значительный прогресс в области строительных материалов, сочетая высокую прочность, гибкость и устойчивость к факторам окружающей среды. Ее использование в различных строительных проектах не только улучшает структурную целостность, но и создает новые возможности для инновационного проектирования и более эффективных методов строительства.

Advantages of the CT4 Machine

- High productivity and efficiency thanks to the simultaneous production of up to 4 rebar rods.

- Reduced polymer consumption due to the innovative pressing system.

- Precision and product quality ensured by the use of high-tech components and control systems.

- Reliability and durability of all machine components, ensuring a long service life and minimal maintenance costs.

The CT4 machine is an ideal solution for enterprises engaged in the production of GFRP rebar, providing high productivity, cost-efficiency, and consistent product quality.

Не упустите шанс сделать свой бизнес более прибыльным с помощью передовых технологий от Composite-Tech! Связаться с нами чтобы узнать больше и оформить заказ.