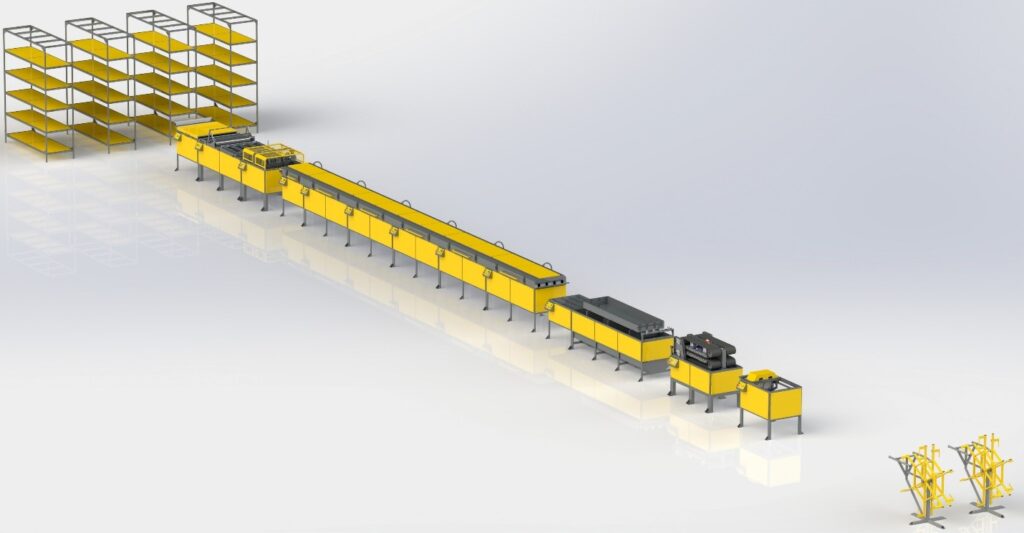

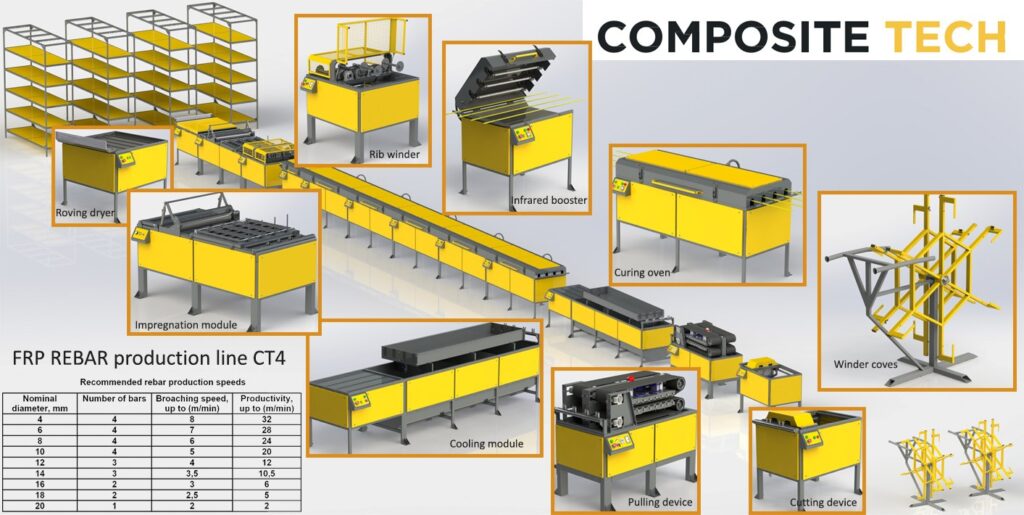

A máquina CT4 foi projetada para a produção de vergalhões de polímero reforçado com fibra de vidro (GFRP) com diâmetros que variam de 4 mm a 20 mm. Ela pode produzir simultaneamente até 4 vergalhões, garantindo alta produtividade e economia. A máquina é composta por vários componentes principais, cada um desempenhando uma função específica no processo de produção.

Principais recursos do CT4

| Característica | Valor |

|---|---|

| Diâmetros de vergalhões | 4 mm - 20 mm |

| Número de hastes | Até 4 |

| Produtividade geral | Até 32 m/min |

| Componentes | 12 módulos principais |

1. Creel

- Função: Segura bobinas de mecha e cria tensão inicial nos fios usando anéis-guia pelos quais os fios passam.

2. Secador Roving

- Função: Alinha e seca os fios da mecha, garantindo distribuição uniforme de calor e teor de umidade ideal para posterior impregnação com resina polimérica.

3. Módulo de impregnação

- Função: Impregna os fios da mecha com resina e os prensa para manter propriedades cruciais do ligante de polímero (fluxo, taxa de cura, temperatura), ao mesmo tempo em que reduz o consumo de polímero por meio de um sistema de prensagem moderno.

4. Enrolador de costelas

- Função: Enrola perfis periódicos (nervuras) com etapas de enrolamento precisas para cada tamanho de vergalhão, garantindo um formato de haste estritamente cilíndrico e removendo o ar da haste impregnada.

5. Amplificador infravermelho

- Função: Acelera o processo de polimerização da resina.

6. Forno de túnel

- Função: Usado para polimerização de resina, onde a resina cura e a barra de reforço GFRP final é formada.

7. Módulo de resfriamento

- Função: Resfria a armadura de PRFV.

8. Dispositivo de tração

- Função: Puxa a armadura de PRFV e determina a velocidade de tração.

9. Dispositivo de corte

- Função: Corta a barra de reforço GFRP no comprimento desejado.

10. Enseadas Winder

- Função: Coloca as barras de reforço GFRP em bobinas.

11. Bobinador Automático (Opcional)

12. Dispositivo para torcer fios de fibra de vidro

- Função: Forma fios nervurados torcendo fios de mecha.

Produtividade

| Diâmetro da barra de reforço (mm) | Número de hastes | Velocidade de tração (m/min) | Produtividade (m/min) |

|---|---|---|---|

| 4 | 4 | 8 | 32 |

| 6 | 4 | 7 | 28 |

| 8 | 4 | 6 | 24 |

| 10 | 4 | 5 | 20 |

| 12 | 3 | 4 | 12 |

| 14 | 3 | 3.5 | 10.5 |

| 16 | 2 | 3 | 6 |

| 18 | 2 | 2.5 | 5 |

| 20 | 1 | 2 | 2 |

Esses dados são aproximados e dependem das características das resinas utilizadas e das condições ambientais.

Especificações técnicas do CT4

| Parâmetro | Valor |

|---|---|

| Fonte de energia | 380 V, 50 Hz |

| Consumo de energia | 50 kW |

| Dimensões | 12000 x 2500 x 2500 mm |

| Peso | 5000 kg |

| Temperatura de operação | 15-30°C |

A barra de reforço GFRP representa um avanço significativo em materiais de construção, combinando alta resistência, flexibilidade e resistência a fatores ambientais. Seu uso em vários projetos de construção em Portugal não apenas melhora a integridade estrutural, mas também cria novas oportunidades para design inovador e práticas de construção mais eficientes.

Vantagens da Máquina CT4

- Alta produtividade e eficiência graças à produção simultânea de até 4 vergalhões.

- Consumo reduzido de polímeros devido ao inovador sistema de prensagem.

- Precisão e qualidade do produto garantida pelo uso de componentes e sistemas de controle de alta tecnologia.

- Confiabilidade e durabilidade de todos os componentes da máquina, garantindo uma longa vida útil e custos mínimos de manutenção.

A máquina CT4 é uma solução ideal para empresas envolvidas na produção de vergalhões de PRFV, proporcionando alta produtividade, custo-benefício e qualidade consistente do produto.

Não perca a oportunidade de tornar seu negócio mais lucrativo com as tecnologias avançadas da Composite-Tech! Contate-nos para saber mais e fazer um pedido.