Quando empreiteiros, distribuidores ou futuros proprietários de fábricas dos EUA conversam conosco, a primeira pergunta é quase sempre a mesma:

Qual é o preço real por metro da barra de reforço de GFRP e qual é o custo real de produção?

A maioria das fontes públicas mostra apenas os preços de varejo. Neste artigo, vamos um passo além e mostramos um exemplo de custo transparente Para o tamanho mais popular no mercado americano:

Barra de reforço GFRP #3 (3/8″), aproximadamente equivalente a 10 mm diâmetro.

- Vamos converter tudo em pés e libras Para o público dos EUA.

- Vamos usar pesos e preços de mercado realistas e verificáveis.

- E mostraremos porquê. O custo real do material por metro quadrado é de apenas alguns centavos.O que explica por que uma fábrica bem administrada pode ser extremamente lucrativa.

Resumo rápido: preços atuais da barra de reforço GFRP #3 nos EUA

A previsão de preços ao público no final de 2025/início de 2026 mostra um cenário bastante consistente:

- Um fornecedor típico dos EUA lista Vergalhão de fibra de vidro de 3/8″ a aproximadamente $0,30 por pé (vendido em barras de 20 pés).

- A própria pesquisa de mercado da Composite-Tech com distribuidores e fabricantes mostra Os preços de varejo para vergalhões de fibra de vidro #3 variam de $0,70 a $0,90 por pé., com O preço de projetos no atacado geralmente fica em torno de $0,55 a $0,65 por pé. dependendo do volume e da região.

Portanto, para um projeto realista nos EUA em 2026, você pode pensar em... Preço por metro da barra de reforço GFRP #3 como aterrissar aproximadamente no $0,55–$0,85/pé largura de banda, considerando descontos e frete.

Esse é o preço de venda. Agora vamos ver o que realmente tem dentro de cada barra.

Passo 1 – Qual o peso da barra de reforço GFRP #3?

Diferentes fabricantes divulgam pesos ligeiramente diferentes para barras de GFRP #3 / 10 mm, mas todos se enquadram na mesma faixa estreita.

Uma tabela típica de peso de vergalhões de GFRP fornece:

- Barra de reforço GFRP de 10 mm: sobre 0,150–0,150 kg por metro (usaremos) 0,157 kg/m (como um valor conservador com base nos dados de engenharia da Composite-Tech)

- Convertendo para unidades americanas, isso dá aproximadamente... 0,10–0,11 lb por pé.

Vamos trabalhar com:

- Peso por metro: 0,157 kg/m

- Peso por pé: 0,157 kg/m × 0,3048 m/ft ≈ 0,048 kg/pé

- Convertendo para libras: 0,048 kg × 2,205 ≈ 0,105 lb/pé

Isso está de acordo com as fichas técnicas públicas de vergalhões de fibra de vidro #3, que citam aproximadamente 0,10 lb/pé.

Para efeito de comparação, A barra de aço carbono #3 pesa cerca de 0,376 a 0,38 lb/pé. – quase quatro vezes mais pesado.

Passo 2 – De que é feita a barra?

Para entender o custo, precisamos analisar o interior do compósito.

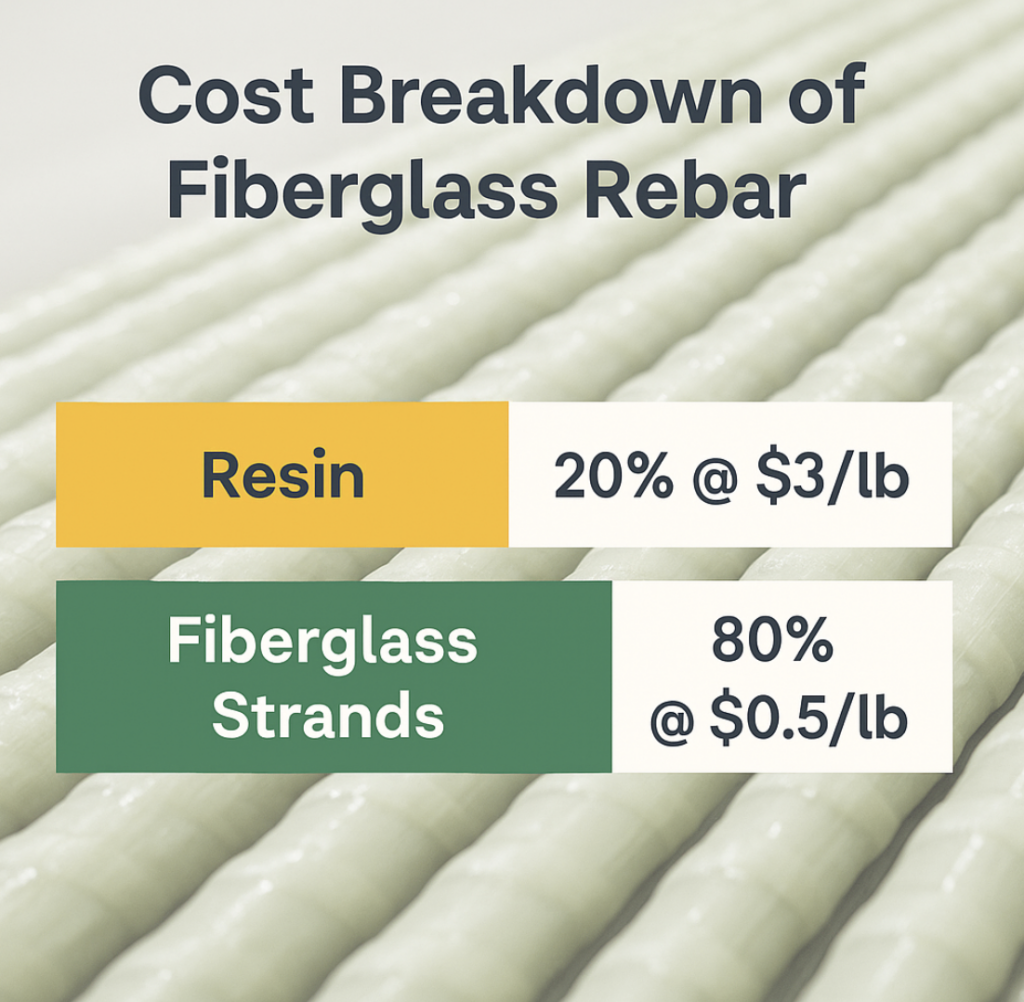

Para vergalhões estruturais de GFRP, é comum ter:

- Fibra de vidro: 70–80% por peso

- Resina (vinil éster, poliéster, epóxi): 20–30% por peso

Para manter os cálculos simples e conservadores, trabalharemos com:

- Vidro 80%

- Resina 20%

Você solicitou o uso dos seguintes preços industriais realistas:

- Resina: $3,00 por kg

- Fibras de vidro em forma de mecha: $0,50 por kg

Esses são preços representativos para compradores de grande volume e são razoáveis para uma fábrica operando em escala.

Etapa 3 – Custo da matéria-prima por quilograma de PRFV (Plástico Reforçado com Fibra de Vidro).

Agora vamos calcular o custo do material misturado para 1 kg de compósito GFRP acabado.

- Porção de resina:

- 20% de 1 kg = 0,20 kg

- 0,20 kg × $3,00/kg = $0.60

- Parte de fibra de vidro:

- 80% de 1 kg = 0,80 kg

- 0,80 kg × $0,50/kg = $0.40

Some-os:

$0,60 + $0,40 = $1,00 por kg de compósito GFRP (≈ $0,45 por libra)

Esse valor já é muito baixo: o "conteúdo" dentro do bar custa praticamente o mesmo que uma garrafa de água por quilo.

Etapa 4 – Custo da matéria-prima por metro de vergalhão de GFRP #3

Sabemos:

- Peso por metro: 0,157 kg/m

Para obter o custo do material por metro:

- Multiplique o peso pelo custo composto por kg:

- 0,157 kg/m × $1,00/kg = $0,157 por metro

Então, um medidor A barra de reforço GFRP #3 contém apenas cerca de 15 a 16 centavos de vidro e resina.

Etapa 5 – Custo da matéria-prima por metro (para preços nos EUA)

Agora converta isso para custo por pé, que é o que a maioria dos compradores americanos leva em consideração.

- Um pé equivale a 0,3048 m.

- Peso por pé que já calculamos: ≈0,048 kg/pé.

- Multiplique por $1,00/kg:

0,048 kg/pé × $1,00/kg = $0,048 por pé

Então o O custo da matéria-prima para um pé de vergalhão de fibra de vidro #3 é pouco inferior a cinco centavos..

Mesmo se considerarmos resina ou vidro mais caros (digamos, $4/kg de resina e $0,80/kg de vidro), o matéria-prima O custo ainda estaria bem abaixo de $0,08 por péA ordem de grandeza não se altera: os ingredientes físicos são notavelmente baratos.

Etapa 6 – Comparação de custos e preços de mercado

Vamos comparar esses números lado a lado:

- Custo da matéria-prima:

~$0,048 por pé (#3 GFRP, 80% fibra de vidro, 20% resina) - Preço típico de venda por atacado:

~$0,55–$0,65 por pé para grandes encomendas nos EUA, dependendo do fornecedor e do volume. - Preço de varejo típico:

Em muitas lojas de materiais de construção dos EUA, o preço varia entre $0,70 e $0,90 por pé quadrado, e em alguns casos, em fornecedores regionais com preços competitivos, chega a cerca de $0,30 por pé quadrado.

Mesmo sendo conservador, existe um Multiplicador de 10 a 15 vezes entre o custo da matéria-prima e o preço de varejo. Essa diferença é o que precisa ser pago:

- eletricidade e gás para fornos;

- trabalho;

- depreciação de equipamentos;

- custos indiretos e de manutenção da planta;

- Controle e testes de qualidade;

- Embalagem, frete e distribuição;

- E, finalmente, lucro para o produtor e o revendedor.

A mensagem principal, no entanto, é simples:

O vidro e a resina dentro de um pé de vergalhão de GFRP #3 custam apenas alguns centavos.

Todo o resto é processo, eficiência e modelo de negócio.

Etapa 7 – Como isso se compara ao aço?

Para entender por que o GFRP parece atraente, devemos pelo menos compará-lo brevemente com... vergalhão de aço tradicional.

Peso

- A barra de aço #3 pesa aproximadamente 0,376–0,38 lb/pé.

- A barra de reforço GFRP #3 tem aproximadamente 0,105 lb/pé, aproximadamente ¼ do peso.

Isso significa:

- manuseio mais barato e fácil no local.

- custos de envio mais baixos

- menor carga morta na estrutura para algumas aplicações

Preços de mercado

Os preços das barras de aço para concreto armado são extremamente voláteis e variam de acordo com a localização, o tamanho e o revestimento. Barras revestidas com epóxi ou galvanizadas para ambientes agressivos são significativamente mais caras do que barras pretas sem revestimento. Em muitas licitações reais que analisamos, A armadura de GFRP #3 acaba na mesma faixa de preço que o aço revestido com epóxi #3. por pé – e às vezes menos quando se consideram as economias em logística e mão de obra.

Ao combinar:

- preço por pé similar (ou ligeiramente superior),

- peso por pé muito menor, e

- Sem corrosão durante a vida útil da estrutura.

O GFRP torna-se muito interessante tanto para empreiteiros quanto para proprietários que pensam em termos de ciclo de vida.

Etapa 8 – Por que a produção em linhas modernas pode ser extremamente lucrativa

O baixo custo da matéria-prima por si só não basta; ainda é necessária uma produção eficiente. É aí que entram os equipamentos modernos, como... Linhas Composite-TechFaz uma grande diferença.

Algumas dicas práticas baseadas em plantas reais:

- Alto rendimento

Uma linha típica Composite-Tech CT-6 pode produzir na ordem de dezenas de milhares de pés de vergalhão #3 por turnoIsso dilui os custos fixos (mão de obra, aluguel, despesas gerais básicas) em um volume enorme de produto. - Consumo de energia razoável

Linhas de vergalhões de GFRP bem projetadas para pequenos diâmetros geralmente desenham dezenas de quilowattsNão centenas. Na maioria das regiões dos EUA, a eletricidade representa uma fração relativamente pequena do custo por metro quadrado em comparação com resina, vidro e logística. - Baixo custo de mão de obra por tonelada

Com a automação adequada, uma pequena equipe pode operar uma linha inteira, o que mantém o custo da mão de obra por tonelada de vergalhão sob controle.

Ao combinar:

- Custo da matéria-prima ≈ $0,048/pé,

- Produção eficiente com consumo moderado de energia e mão de obra.,

- Preço de venda por atacado em torno de $0,55–$0,65/pé,

Agora dá para entender por que investidores sérios estão considerando as fábricas de PRFV (Plástico Reforçado com Fibra de Vidro) como um negócio atraente, e não apenas como uma curiosidade técnica.

Etapa 9 – Contexto: o mercado de vergalhões de PRFV está crescendo rapidamente

Tudo isso está inserido em um mercado global em rápido crescimento.

Relatórios recentes do setor preveem que o mercado de vergalhões de PRFV crescerá de cerca de 1.600,69 bilhão em 2025 para 1.190,19 bilhão em 2030., com uma taxa de crescimento anual composta de aproximadamente 11.5%.

Os principais fatores são:

- a necessidade de reforço livre de corrosão em ambientes marinhos e costeiros;

- infraestrutura de água e esgoto, onde a exposição a produtos químicos destrói o aço;

- e a pressão por pontes e estacionamentos de baixa manutenção e longa vida útil.

Em outras palavras, a demanda não é teórica. Ela está sendo incorporada às especificações pelos Departamentos de Transporte, concessionárias de serviços públicos e grandes proprietários privados.

O que isso significa se você estiver comprando ou produzindo vergalhões de PRFV (Plástico Reforçado com Fibra de Vidro)?

Se você é um empreiteiro ou engenheiro:

- Quando você vê Preço da barra de reforço GFRP por metro Em uma citação, lembre-se de que o O material dentro dessa barra custa apenas alguns centavos..

- O valor adicional que você paga em relação ao aço está lhe proporcionando uma vantagem. resistência à corrosão, menor peso e maior vida útil, não “materiais exóticos”.

Se você é um futuro proprietário ou investidor de planta:

- Existe um grande diferença entre o custo da matéria-prima (~$0,048/pé) e o preço de mercado (~$0,55–$0,85/pé) para vergalhão de GFRP #3.

- Com os equipamentos e o sistema de qualidade adequados, essa lacuna pode se transformar em... margens muito saudáveis, mesmo quando você pratica preços agressivos para ganhar projetos.

- Prevê-se que o mercado global continue a crescer até 2030 e mais além, impulsionado por necessidades reais de infraestrutura, e não pela moda.

Conclusão

Os números são claros:

- Um pé de vergalhão de GFRP #3 (3/8″) contém menos de cinco centavos de vidro e resina.

- O mesmo pé costuma ser vendido no mercado americano por dez a quinze vezes esse valor.

- Com linhas de produção eficientes e bons canais de venda, uma fábrica de PRFV (Plástico Reforçado com Fibra de Vidro) não é apenas um projeto tecnicamente interessante – é uma oportunidade de negócio muito real.

Para proprietários e especificadores, isso também explica o porquê. vergalhões compostos Veio para ficar: cumpre o que promete. durabilidade a longo prazo sem custos iniciais proibitivos.

Saber mais: