Com a chegada do Polímero Reforçado com Fibra (mais comumente conhecido como PRFV) ao mercado global, seus campos de aplicação estão em constante expansão. Não são apenas as propriedades dos polímeros que importam; diversos fatores cruciais influenciam a demanda por Produtos de FRP. Atualmente, as barras de reforço de FRP substituem com sucesso as barras de ferro em muitos setores, desde agricultura, indústrias químicas e farmacêuticas e aplicações biomédicas até engenharia civil e industrial.

Contente

Reforço de concreto: PRFV vs. aço

Historicamente, o concreto conquistou a reputação de um dos materiais de construção mais populares, especialmente quando reforçado com barras de aço para compensar a baixa resistência à tração e a fragilidade do concreto na construção civil. Por sua vez, as barras de ferro são relativamente baratas em termos de custos de fabricação. Infelizmente, em ambientes agressivos expostos à água e à umidade, a ferrugem e a corrosão reduzem a durabilidade geral.

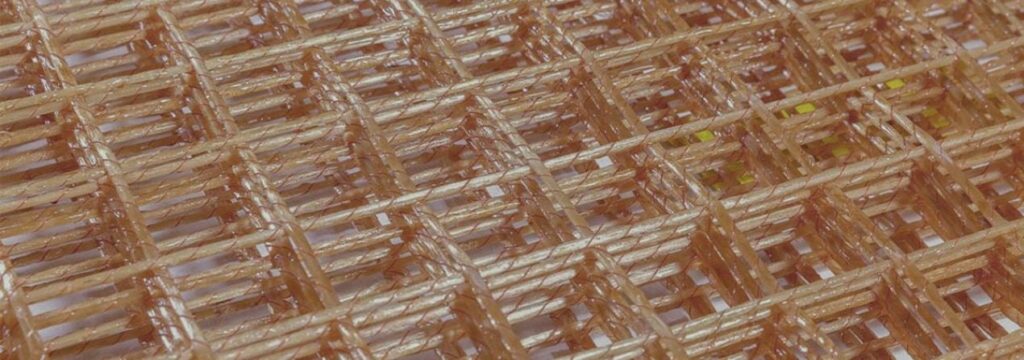

Vergalhões compostos que não sofrem corrosão tornaram-se um substituto confiável para barras de aço em estruturas de concreto, como píeres e decks, canais, molhes, plataformas offshore, etc. Resistentes a uma infinidade de produtos químicos e ao sal das estradas, os vergalhões de PRFV são utilizados em pontes e estradas, fundações e muros de contenção, plantas de tratamento de águas residuais e petroquímicas, entre outros. Por ser um material não condutor, o PRFV não interfere na operação de dispositivos elétricos e é utilizado em construções militares, torres de aeroportos e instituições médicas equipadas com aparelhos de ressonância magnética.

Além da durabilidade, resistência à tração e baixa necessidade de manutenção, a relação custo-benefício dos produtos de PRFV se beneficia de seu menor peso (cerca de ¼ de uma barra de aço comparável): mais vergalhões por caminhão dentro dos limites de carga, menos máquinas de içamento e ferramentas de corte necessárias, e menos carga sobre os operários envolvidos na instalação dos vergalhões. Uma melhor relação resistência à tração/peso resulta em um peso mais leve das estruturas finais, o que é de vital importância em ambientes com baixa capacidade de carga.

Benefícios cientificamente comprovados

O estudo recente realizado por Ginghis Maranan, Allan Manalo et al. (“Uma Visão Geral do Uso de Vergalhões Compostos como Reforço em Estruturas de Concreto Geopolimérico”) demonstrou que os vergalhões compostos representam uma solução mais ecológica, durável e econômica para aplicações na construção. Por serem mais leves e resistentes à corrosão, os produtos compósitos de PRFV substituíram as barras de aço em estruturas de concreto em diversos setores, especialmente em projetos em meios agressivos, como construção naval, indústria química e engenharia civil.

O compósito de FRP é capaz de quadruplicar a vida útil de estruturas de concreto em comparação com construções reforçadas com barras de ferro. Estruturas de concreto reforçadas com barras de metal apresentam microfissuras devido à ferrugem do metal e exigem testes de tração regulares. Vergalhões de FRP resistentes à corrosão usados em construções de concreto podem dobrar a vida útil estrutural em comparação com a tecnologia de construção convencional baseada em concreto reforçado com ferro. Ao longo de 30 anos de implementação de vergalhões compostos em construções de concreto, estruturas reforçadas com FRP demonstraram taxas de degradação mais baixas (em torno de 40%), incluindo projetos em ambientes severos (quando expostos a soluções alcalinas ou ácidas, altas temperaturas, etc.), como canais de drenagem costeira na região MENA e vigas de borda nos EUA e Canadá.

Apesar dos custos iniciais de fabricação mais altos em comparação à produção de barras de aço, os custos do ciclo de vida na construção de concreto são menores, devido ao menor transporte, menores custos de reparo e manutenção e maior vida útil.

Abrindo Novos Horizontes: Vergalhões Ocos

Introduzido no mercado japonês na década de 1980, o vergalhão composto conquistou um mercado global. A recente introdução do vergalhão alveolar abriu novos campos de aplicação no nicho da engenharia civil: controle climático para circulação de fluidos de aquecimento, transmissão de voz, fibra óptica protegida e fiação elétrica, etc.

O passo crucial em expansão da participação de mercado para vergalhões compostos é sua inclusão em códigos de construção emitidos por autoridades reguladoras em todo o mundo. Atualmente, os compósitos de PRFV estão ganhando cada vez mais autoridade e confiança entre as autoridades de construção e se tornando um material comum para projetos em diversos setores.

É lógico que a aplicação de vergalhões de PRFV (Plástico Reforçado com Fibra de Vidro) na construção de concreto continuará se expandindo. Pesquisas globais comprovaram a sustentabilidade da produção de vergalhões de PRFV e estudaram a impacto ambiental dos compósitos de FRP. Além de suas impressionantes características físicas e benefícios econômicos, os produtos de FRP são sustentáveis e ecologicamente corretos — e essa qualidade não pode ser superestimada nos esforços globais para preservar o meio ambiente.