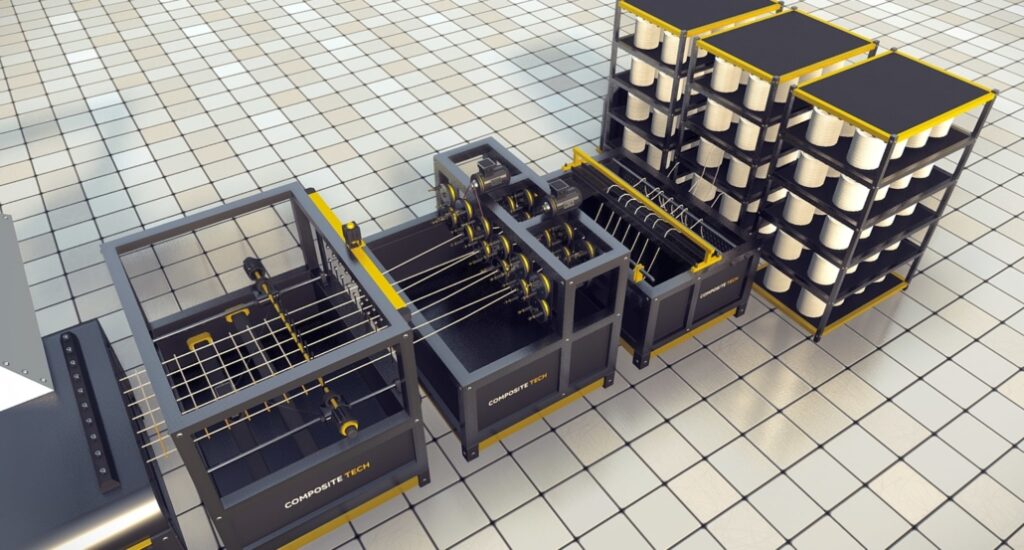

La nostra linea di produzione di barre di rinforzo in rete FRP è stata perfezionata nel corso degli ultimi 10 anni e ha ora raggiunto il suo stadio di prodotto di punta. Di conseguenza, abbiamo ottenuto un flusso di processo di produzione non-stop e ci siamo assicurati che richiedesse da zero a nessun input di manutenzione, producendo al contempo una qualità costantemente elevata del prodotto finale alla massima potenza.

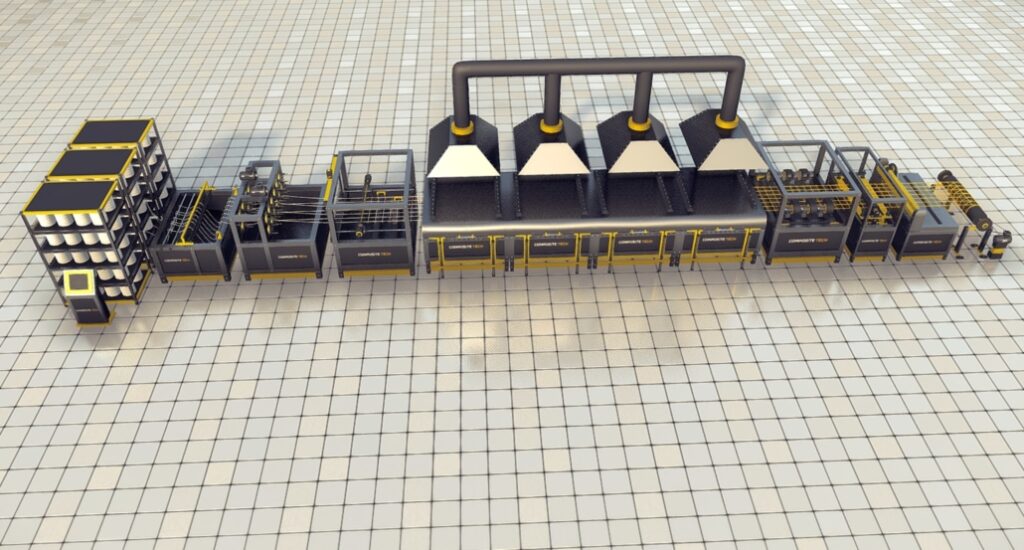

Produciamo 2 diverse linee di produzione di reti GFRP:

Le nostre attrezzature sono progettate per essere affidabili, altamente produttive e uniche nella tecnologia che utilizziamo! Tutti i nostri sviluppi e innovazioni sono brevettati, il che garantisce non solo un'elevata efficacia del tuo investimento, ma anche un mercato libero dalla concorrenza. Inoltre, per garantire l'affidabilità di tutti i moduli della linea di produzione utilizziamo solo quei componenti che hanno superato i nostri rigorosi test e valutazioni delle prestazioni.

Grazie all'acquisizione di attrezzature per la produzione di maglie in plastica rinforzata con fibra di vetro Composite-Tech, i nostri clienti in Italia possono inoltre ottenere i seguenti risultati:

-

- Assistenza nella scelta dei locali speciali

- I nostri specialisti eseguono l'installazione delle apparecchiature e svolgono lavori di messa in servizio

- Formazione del personale

- Consulenza continua ai tuoi esperti tecnici

Caratteristiche tecniche

Caratteristiche tecniche della linea di produzione della rete GFRP:

| Scopo: | Rilascio di rete composita in fibra di vetro o basalto |

| Diametro di produzione: | Da 2 mm a 10 mm. |

| voltaggio: | 380 V / 50 Hz |

| Cella della griglia: | 50×50, 100×100, 150×150, 200×200, 300×300 |

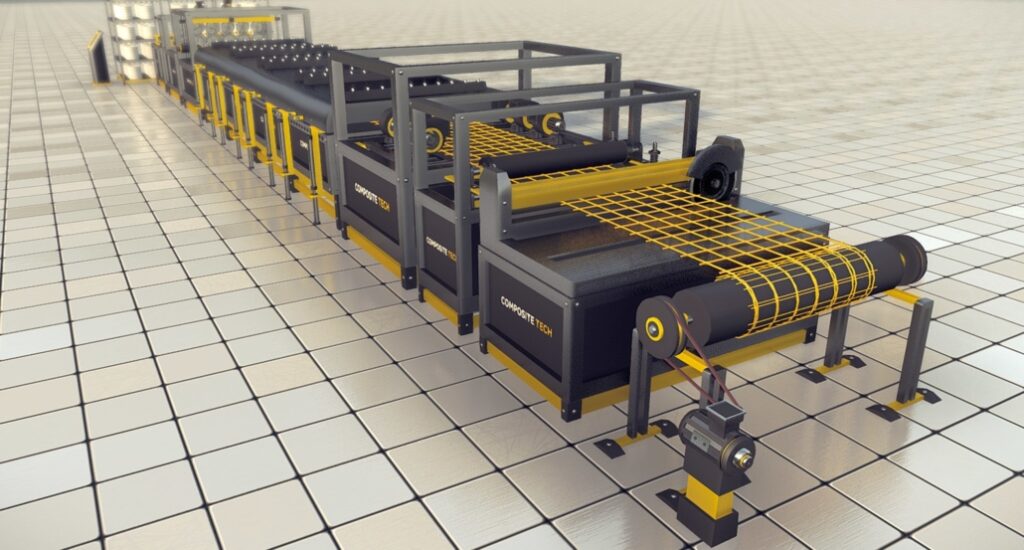

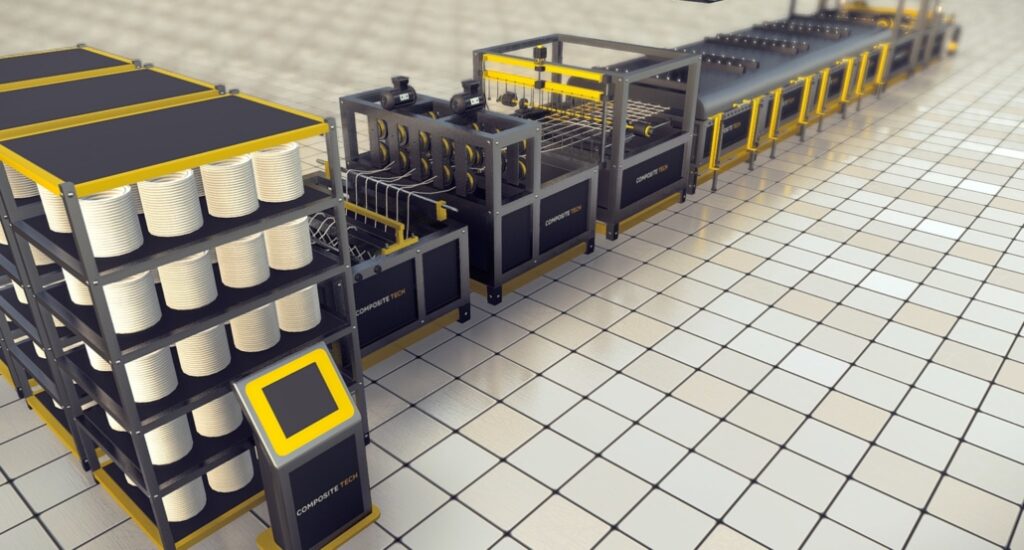

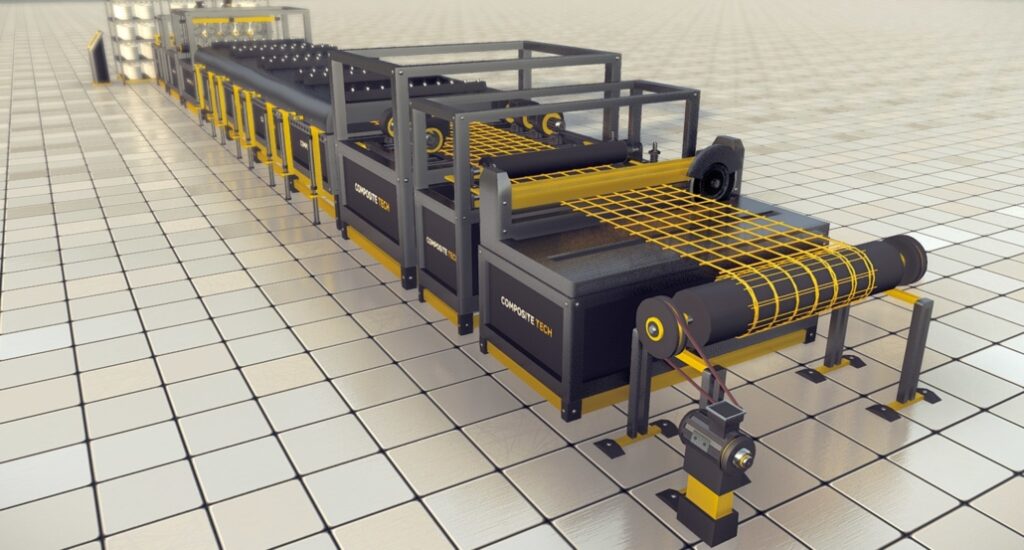

Produciamo due tipi di attrezzature per la produzione di reti composite:

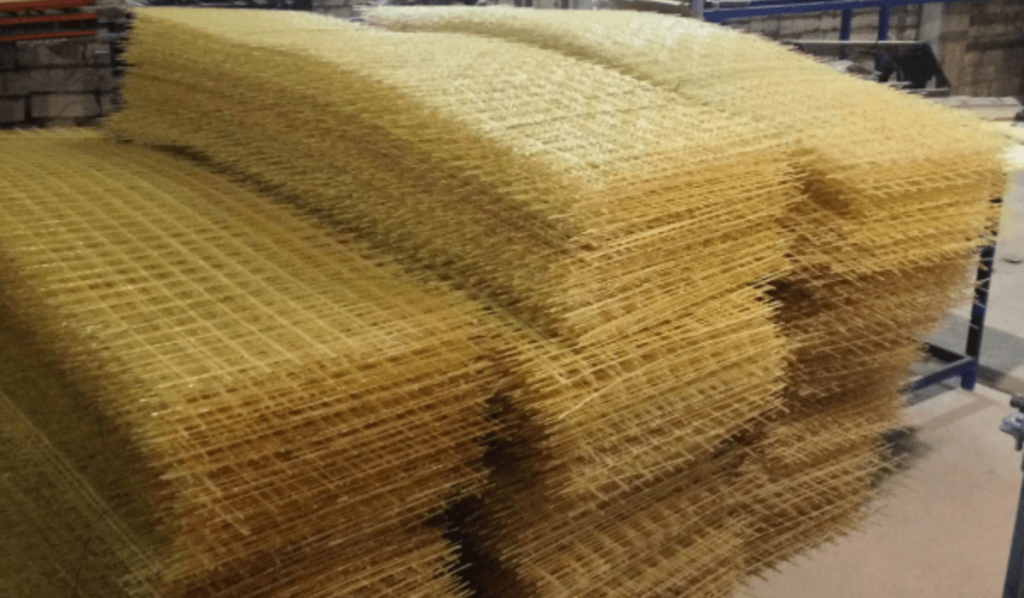

Barre di rinforzo in FRP prodotto dalle nostre attrezzature presenta caratteristiche di resistenza migliorate (resistenza alla rottura, alla rottura e alla trazione), apprezzate dalle aziende edili professionali in tutta Italia.

Abbiamo raggiunto questi risultati grazie a un grande lavoro svolto in collaborazione con diverse università e centri di ricerca specializzati in materiali compositi e tecnologie avanzate per l'industria edile.

| Scopo: |

Attrezzature per la produzione di maglie GFRP 1 m di larghezza |

| Cella a griglia | 50×50, 100×100, 150×150, 200×200 |

| Diametri disponibili: | 2-8 |

| Lunghezza della macchina | 18 milioni |

| Altezza: | 1,8 milioni |

| Larghezza: | 1,2 milioni |

| Energia: | 35 kW |

| Prestazioni della linea: | 3-8 metri al minuto |

| Scopo: |

Attrezzatura per la produzione di maglie composite larghe 2 m di larghezza |

| Cella a griglia | 50×50, 100×100, 150×150, 200×200, 300×300 |

| Diametri disponibili: | 2-12 |

| Lunghezza della macchina | 28 milioni |

| Altezza: | 1,8 milioni |

| Larghezza: | 2,4 milioni |

| Energia: | 45 kW |

| Prestazioni della linea: |

Produzione chiavi in mano di barre d'armatura in GFRP in Italia!

Confrontando il prezzo di vendita delle barre d'armatura in GFRP con quello delle barre d'armatura in acciaio, si ottiene un margine di profitto di oltre 120%!

Ottieni la tua linea di produzione in soli 2 mesi dall'ordine e rientra del tuo investimento in soli 3 mesi dall'avvio della produzione.

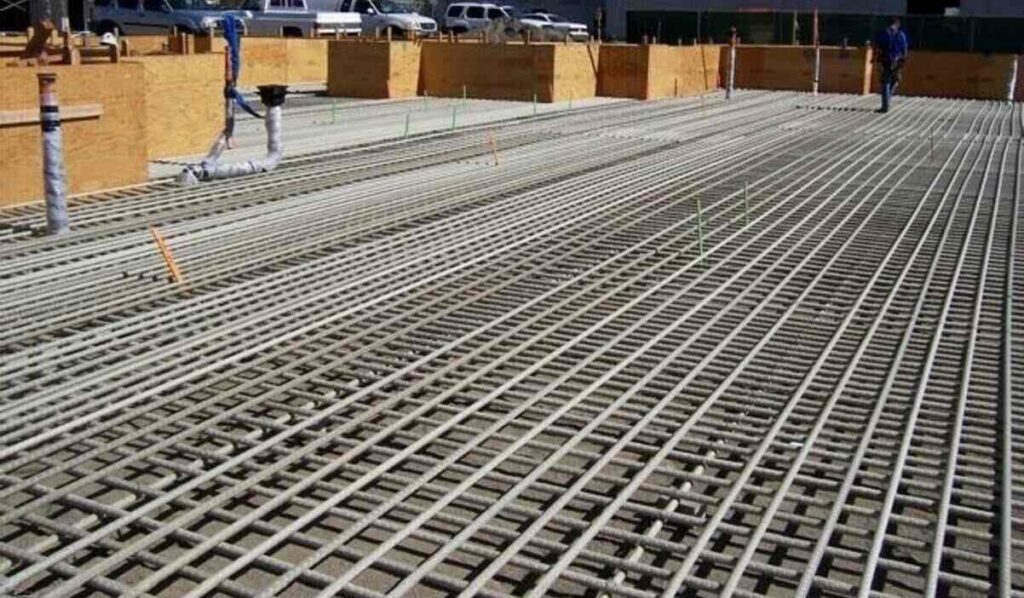

Ingegneria Civile

RINFORZO DI STRUTTURE IN PIETRA E ARMOCAMAGE.

RINFORZO DELLO STRATO DI FACCIATA DI STRUTTURE PROTETTIVE A TRE STRATI.

RINFORZO DI PIASTRE DI CALCESTRUZZO.

RINFORZO DEL PAVIMENTO IN LOCALI RESIDENZIALI.

RINFORZO DELLE CUCITURE DEGLI STRATI ORIZZONTALI.

RINFORZO DEL TELO STRADALE CON UNA GRIGLIA COMPOSITA

STOCCAGGIO RIFIUTI CHIMICI DI RINFORZO

RINFORZO DI PAVIMENTAZIONI INDUSTRIALI.

RINFORZO DELLE STRUTTURE DI TRATTAMENTO

IMPOSTAZIONI DI RINFORZO PER IL TRATTAMENTO DEI RIFIUTI.

Ingegneria industriale

Agricoltura

RINFORZO DELLO STOCCAGGIO DEI RIFIUTI AGRICOLI

RINFORZO DELLO STOCCAGGIO DEI RIFIUTI AGRICOLI.

RINFORZO DEI PAVIMENTI IN COMPLESSI DI ALLEVAMENTO ZIMMERICO, AZIENDE AGRICOLE.

APPLICAZIONE DI UNA GRIGLIA COMPOSITA COME RIVESTIMENTO PER STRADE.

RINFORZO DELLE PIASTRE STRADALI.

RINFORZO DELLA STRADA.

Costruzione stradale

Costruzione di ponti e opere idrauliche

RINFORZO DELLE PIASTRE DEL PONTE MESTER

RINFORZO DELLE MARCIAPIEDE

RINFORZO E REALIZZAZIONE DI STRUTTURE COSTRUZIONI E IDROTECNICHE.

Composite-Tech's Attrezzature per la produzione di GFRP negli Stati Uniti