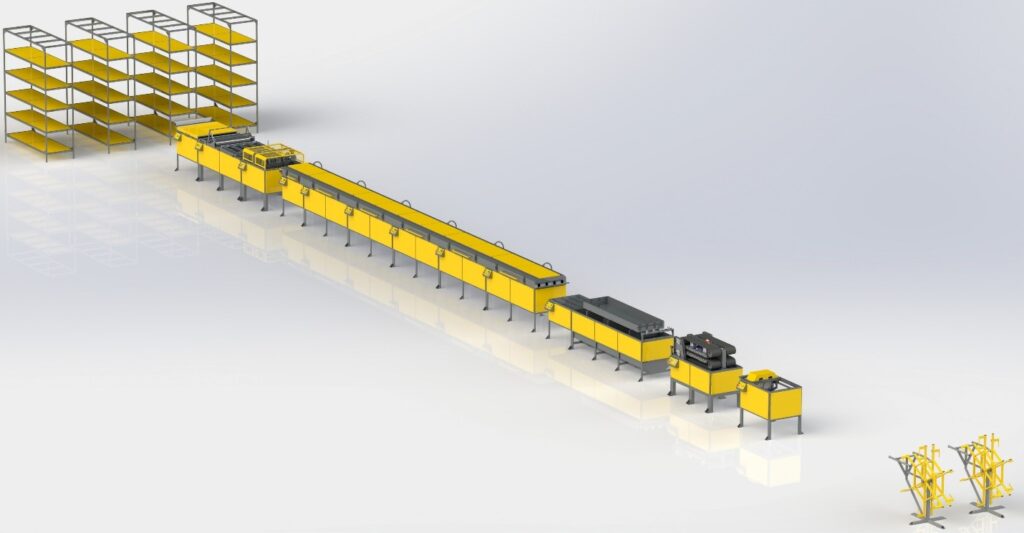

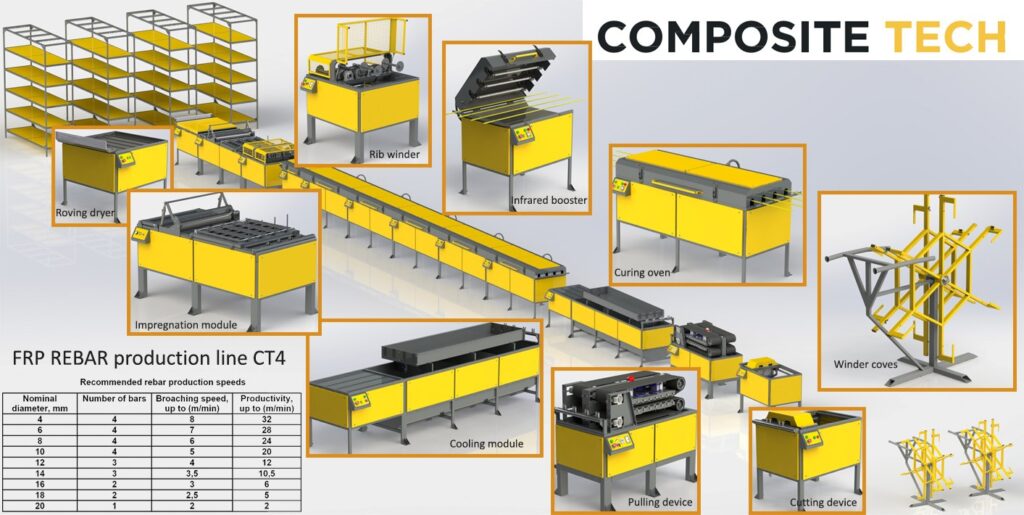

La macchina CT4 è progettata per la produzione di barre d'armatura in polimero rinforzato con fibra di vetro (GFRP) con diametri da 4 mm a 20 mm. Può produrre simultaneamente fino a 4 barre d'armatura, garantendo elevata produttività ed economicità. La macchina è composta da diversi componenti chiave, ognuno dei quali svolge una funzione specifica nel processo produttivo.

Caratteristiche principali di CT4

| Caratteristica | Valore |

|---|---|

| Diametri delle barre d'armatura | 4 millimetri - 20 millimetri |

| Numero di aste | Fino a 4 |

| Produttività complessiva | Fino a 32 m/min |

| Componenti | 12 moduli principali |

1. Cesta

- Funzione: Contiene le bobine di roving e crea la tensione iniziale nei fili mediante anelli guida attraverso i quali passano i fili.

2. Essiccatore a roving

- Funzione: Allinea e asciuga i fili di roving, garantendo una distribuzione uniforme del calore e un contenuto di umidità ottimale per la successiva impregnazione con resina polimerica.

3. Modulo di impregnazione

- Funzione: Impregna i fili di roving con resina e li pressa per mantenere le proprietà essenziali del legante polimerico (flusso, velocità di polimerizzazione, temperatura), riducendo al contempo il consumo di polimero tramite un moderno sistema di pressatura.

4. Avvolgitore per costole

- Funzione: Avvolge profili periodici (nervature) con fasi di avvolgimento precise per ogni dimensione di barra d'armatura, garantendo una forma rigorosamente cilindrica della barra e rimuovendo l'aria dalla barra impregnata.

5. Booster a infrarossi

- Funzione: Accelera il processo di polimerizzazione della resina.

6. Forno a tunnel

- Funzione: Utilizzato per la polimerizzazione della resina, durante la quale la resina si indurisce e si forma la barra d'armatura finale in GFRP.

7. Modulo di raffreddamento

- Funzione: Raffredda le barre d'armatura in GFRP.

8. Dispositivo di trazione

- Funzione: Tira la barra d'armatura in GFRP e ne determina la velocità di trazione.

9. Dispositivo di taglio

- Funzione: Taglia la barra d'armatura in GFRP alla lunghezza desiderata.

10. Winder Coves

- Funzione: Dispone le barre di armatura in GFRP in bobine.

11. Avvolgitore automatico (opzionale)

12. Dispositivo per torcere i fili di fibra di vetro

- Funzione: Forma un filo nervato torcendo i fili di roving.

Produttività

| Diametro del tondino (mm) | Numero di aste | Velocità di trazione (m/min) | Produttività (m/min) |

|---|---|---|---|

| 4 | 4 | 8 | 32 |

| 6 | 4 | 7 | 28 |

| 8 | 4 | 6 | 24 |

| 10 | 4 | 5 | 20 |

| 12 | 3 | 4 | 12 |

| 14 | 3 | 3.5 | 10.5 |

| 16 | 2 | 3 | 6 |

| 18 | 2 | 2.5 | 5 |

| 20 | 1 | 2 | 2 |

Questi dati sono approssimativi e dipendono dalle caratteristiche delle resine utilizzate e dalle condizioni ambientali.

Specifiche tecniche del CT4

| Parametro | Valore |

|---|---|

| Alimentazione elettrica | 380 V, 50 Hz |

| Consumo energetico | 50 kW |

| Dimensioni | 12000 x 2500 x 2500 mm |

| Peso | 5000 kg |

| Temperatura di esercizio | 15-30°C |

Le barre in polimero rinforzato rappresentano un significativo progresso nei materiali da costruzione, combinando elevata resistenza, flessibilità e resistenza ai fattori ambientali. Il loro utilizzo in diversi progetti edilizi in Italia non solo migliora l'integrità strutturale, ma crea anche nuove opportunità per una progettazione innovativa e pratiche di costruzione più efficienti.

Vantaggi della macchina CT4

- Elevata produttività ed efficienza grazie alla produzione simultanea di un massimo di 4 barre di armatura.

- Consumo ridotto di polimeri grazie all'innovativo sistema di pressatura.

- Precisione e qualità del prodotto garantita dall'impiego di componenti e sistemi di controllo ad alta tecnologia.

- Affidabilità e durata di tutti i componenti della macchina, garantendo una lunga durata e costi di manutenzione minimi.

La macchina CT4 è la soluzione ideale per le aziende impegnate nella produzione di barre d'armatura in GFRP, in quanto garantisce elevata produttività, economicità e qualità costante del prodotto.

Non perdere l'occasione di rendere la tua attività più redditizia con le tecnologie avanzate di Composite-Tech! Contattaci per saperne di più ed effettuare un ordine.