През последните години композитната арматура, особено арматурата от армиран със стъклени влакна полимер (GFRP), придоби популярност в строителната индустрия. Това се дължи на превъзходните му свойства, като леко тегло, устойчивост на корозия и висока издръжливост. Но колко изгодно е да се произвежда такава арматура от гледна точка на производствените разходи? Нека го разбием с конкретни примери.

Ключови изводи

- ТОсновното предимство на GFRP арматурата се крие в нейната икономическа ефективност.

- Производствената цена на един метър арматурно желязо от GFRP с диаметър 10 мм е приблизително tely. $0.152.

- Машините Composite-Tech могат да произвеждат до 10 000 линейни метра арматурно желязо по време на 8-часова смяна, с минимална консумация на енергия — само 20 kW на час.

- Преминаването към FRP арматура може да доведе до икономии на разходи до 300% в сравнение с традиционната стоманена арматура.

Какво е фибростъкло арматура?

GFRP арматурата се състои от пръти, изработени от нишки от стъклени влакна, импрегнирани с епоксидна смола. Този материал се използва широко в строителството, защото е по-лек, по-здрав и по-издръжлив от традиционната стоманена арматура. Основното му предимство обаче е неговата икономическа ефективност.

Разходите за производство на GFRP арматура

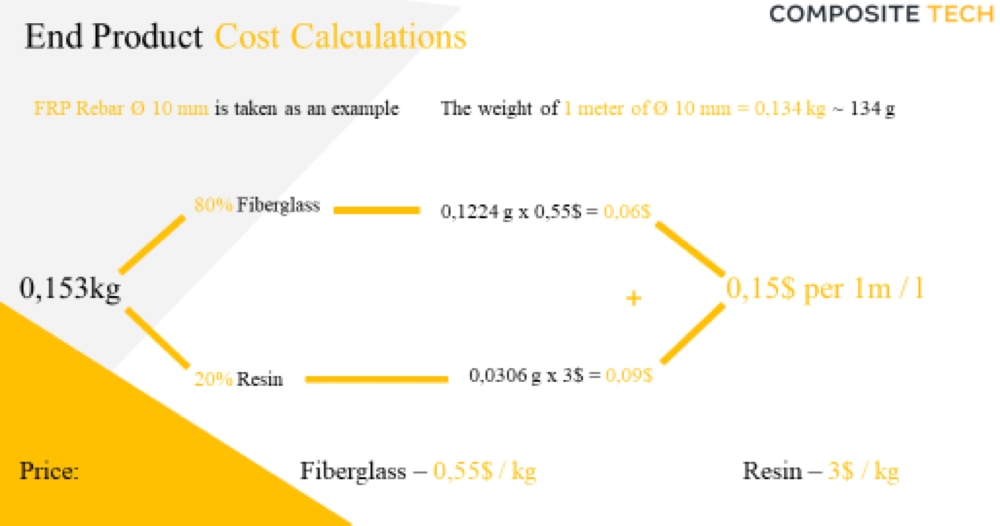

За да разберем разходите за производство на GFRP арматура, нека вземем за пример арматура с диаметър 10 mm. Теглото на един линеен метър такава арматура е 150 грама.

Състав на GFRP арматура:

- 20% – епоксидна смола

- 80% – ровинг със стъклени влакна

Разходи за суровини:

- Епоксидна смола: $3 на килограм

- Ровинг от стъклени влакна: $0.5 на килограм

Сега нека изчислим количеството суровина, необходимо за производството на един метър арматура и нейната цена:

Епоксидна смола:

- 20% от 150 грама = 30 грама

- Цена на метър: 30 g×3 USD/kg=0,09 USD30 \, \text{g} \times 3 \, \text{USD/kg} = 0,09 \, \text{USD}30g×3USD/kg=0,09USD

Ровинг от стъклени влакна:

- 80% от 150 грама = 120 грама

- Цена на метър: 120 g×0,5 USD/kg=0,06 USD120 \, \text{g} \times 0,5 \, \text{USD/kg} = 0,06 \, \text{USD}120g×0,5USD/kg=0,06USD

По този начин цената на суровината за производството на един линеен метър арматура от 10 mm GFRP е:

Разходи за суровини=0,09 USD+0,06 USD=0,15 USD\text{Разходи за суровини} = 0,09 \, \text{USD} + 0,06 \, \text{USD} = 0,15 \,

\text{USD}Разходи за суровини=0,09USD+0,06USD=0,15USD

Производствени разходи

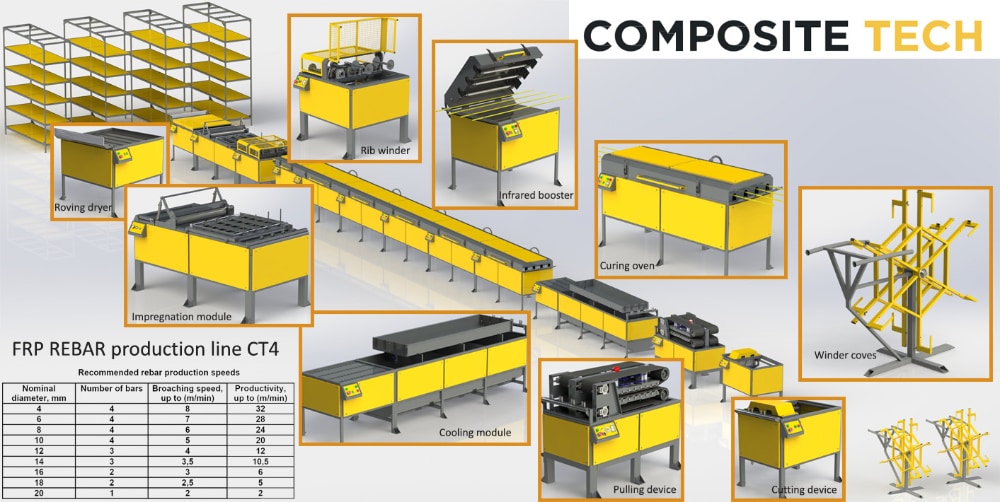

При изчисляване на производствените разходи е важно да се вземат предвид не само разходите за суровини, но и разходите за електроенергия и амортизацията на оборудването. Нека да разгледаме един пример с оборудване Composite-Tech, което е сред най-производителните и ефективни на пазара.

Производителност на композитно-технологично оборудване:

- Производствен капацитет: до 10 000 линейни метра 10 mm GFRP арматура на смяна (8 часа).

- Консумирана мощност: 20 kW на час.

Нека изчислим разходите за електроенергия за една смяна:

Консумация на енергия на смяна=20 kW/h×8 h=160 kW\text{Консумация на енергия на смяна} = 20 \, \text{kW/h} \times 8 \, \text{h} = 160 \, \text{kW}Консумация на енергия на смяна=20kW/h×8h=160kW

Ако приемем среден разход на електроенергия от $0.1 на kW, цената на електроенергия за една смяна ще бъде:

160 kW×0,1 USD/kW=16 USD160 \, \text{kW} \times 0,1 \, \text{USD/kW} = 16 \, \text{USD}160kW×0,1USD/kW=16USD

Сега, за да изчислим цената на метър арматура, разделяме цената на електроенергията на общия брой произведени метри:

Цена на електроенергия на метър=16 USD10 000 m=0,0016 USD\text{Цена на електроенергия на метър} = \frac{16 \, \text{USD}}{10 000 \, \text{m}} = 0,0016 \, \text{USD}Цена на електроенергия на метър=10 000m16USD=0,0016USD

Обща производствена цена на метър GFRP арматура

Сега нека обединим всички разходи:

- Разходи за суровини: 0,15 USD

- Разходи за електроенергия: 0,0016 USD

Така общата производствена цена за един линеен метър GFRP арматура е:

0,15 USD+0,0016 USD=0,1516 USD0,15 \, \text{USD} + 0,0016 \, \text{USD} = 0,1516 \, \text{USD}0,15USD+0,0016USD=0,1516USD

Следователно производствените разходи за един метър GFRP арматура с диаметър 10 mm са приблизително tely 0,152 USD.

Предимства на оборудването Composite-Tech

Composite-Tech предлага оборудване, което позволява максимална производителност при минимален разход на енергия. Машините на Composite-Tech могат да произвеждат до 10 000 линейни метра арматура на 8-часова смяна с минимална консумация на енергия — само 20 kW на час. Това е 30-40% по-ефективен от други пазарни конкуренти. Нещо повече, използването на такива машини намалява амортизацията и оперативните разходи, като допълнително намалява цената на крайния продукт.

Сравнение на разходите за GFRP и стоманена арматура

Стоманената арматура има значително по-високи производствени разходи. Например стоманена арматура с диаметър 10 mm струва около 0,5 USD на метър. Това е три пъти по-скъпо от цената на произведената GFRP арматура Composite-Tech оборудване.

Освен това GFRP арматурата има предимства като устойчивост на корозия, което значително увеличава живота на конструкциите и намалява разходите за поддръжка и ремонт. По този начин преминаването към FRP арматура може да спести до 300% в сравнение с използването на стоманена арматура.

Научете повече за FRP арматура срещу стоманена арматура

Заключение

Производството на GFRP арматура с помощта на модерно оборудване от Composite-Tech е икономически изгодно решение, осигуряващо ниски производствени разходи и висока производителност. FRP арматура е не само по-евтин за производство, но също така предлага множество предимства, които го правят идеален избор за съвременни строителни проекти.

Научете повече за Защо клиентите по света избират Composite-Tech като най-надеждния доставчик на оборудване за производство на GFRP арматура

Искаме да открием завод в Делхи, Индия. Ще ни помогнете ли?

Търся технология за производствена линия от GFRP. Моля, споделете приблизителна цена.