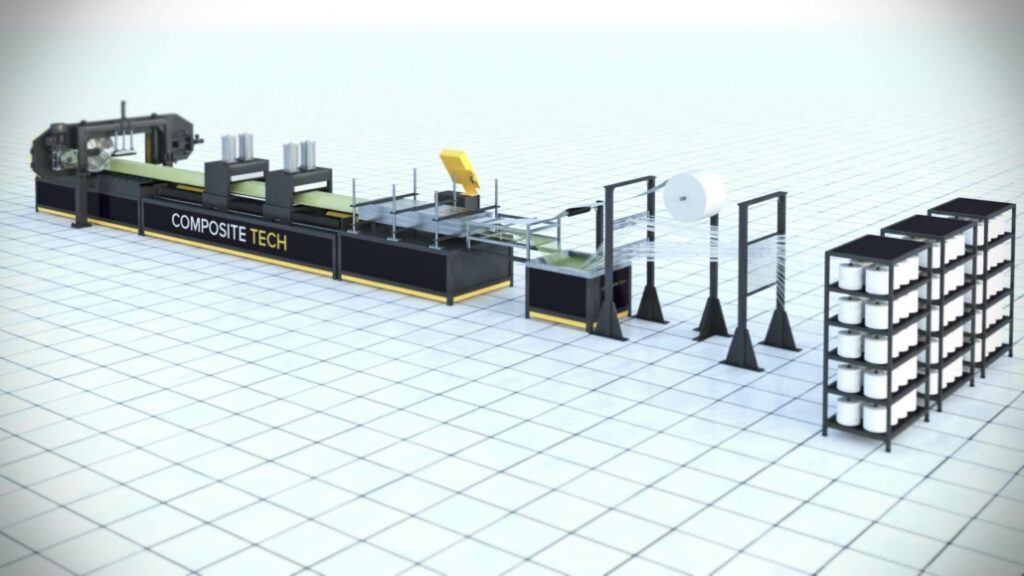

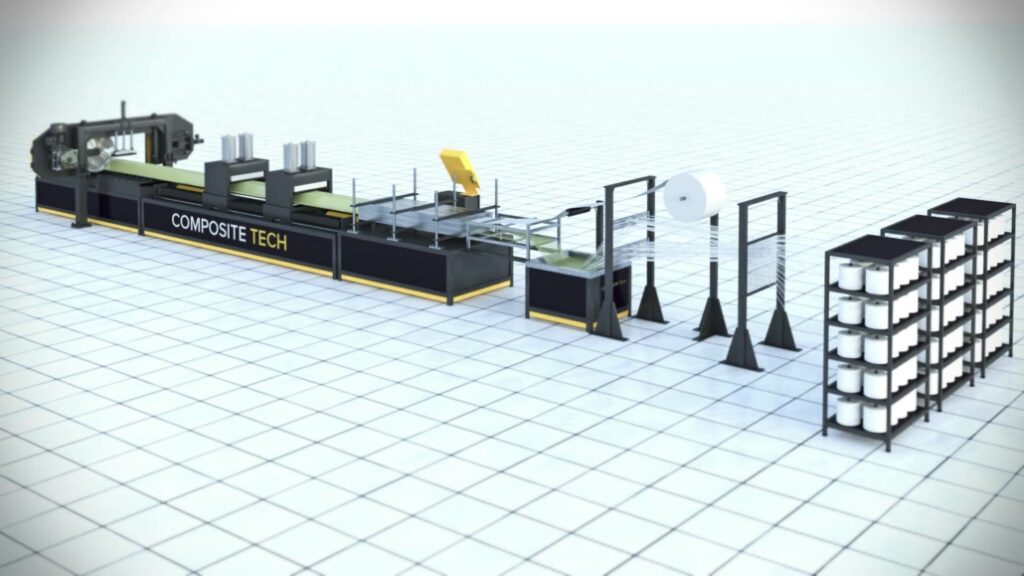

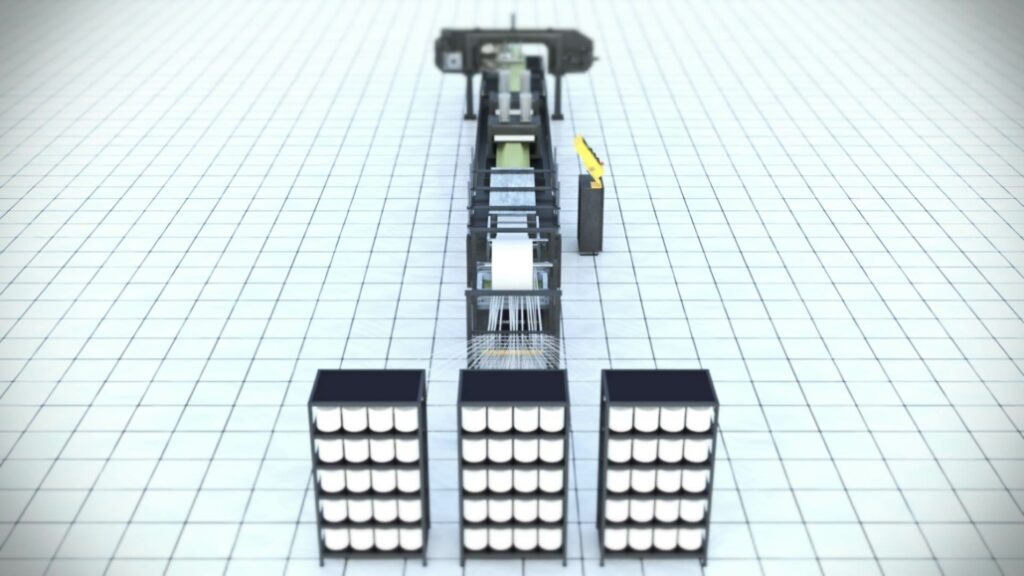

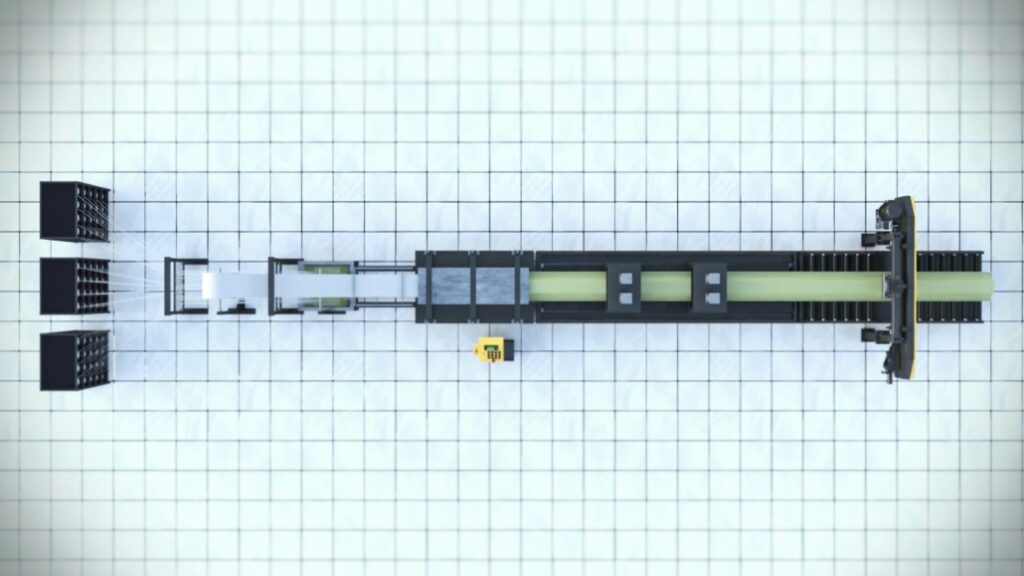

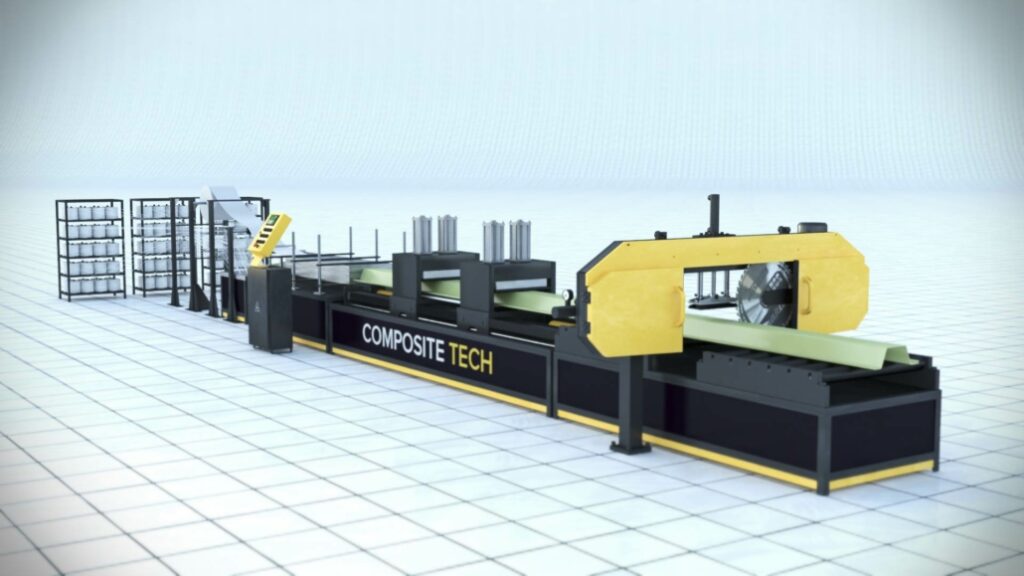

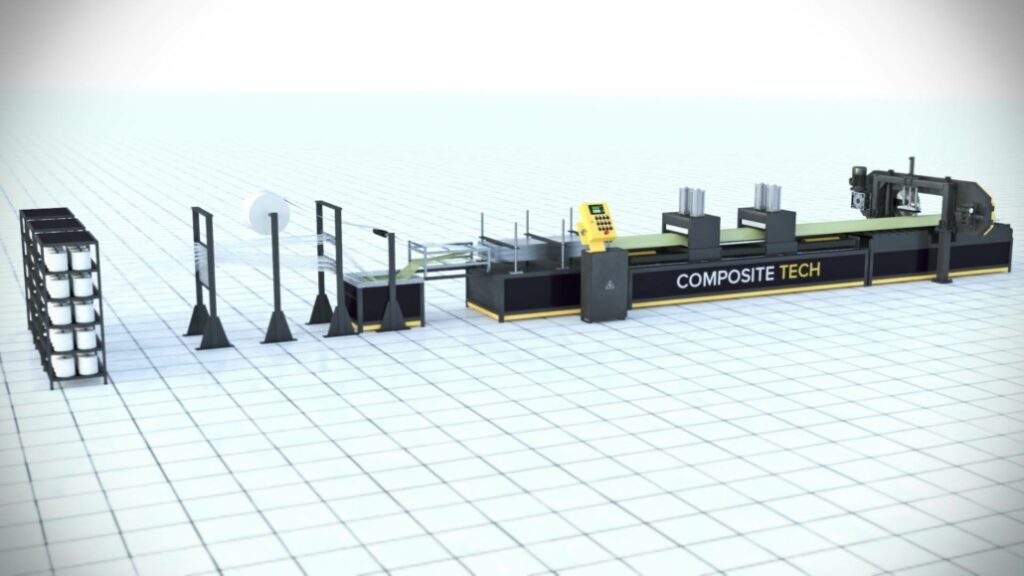

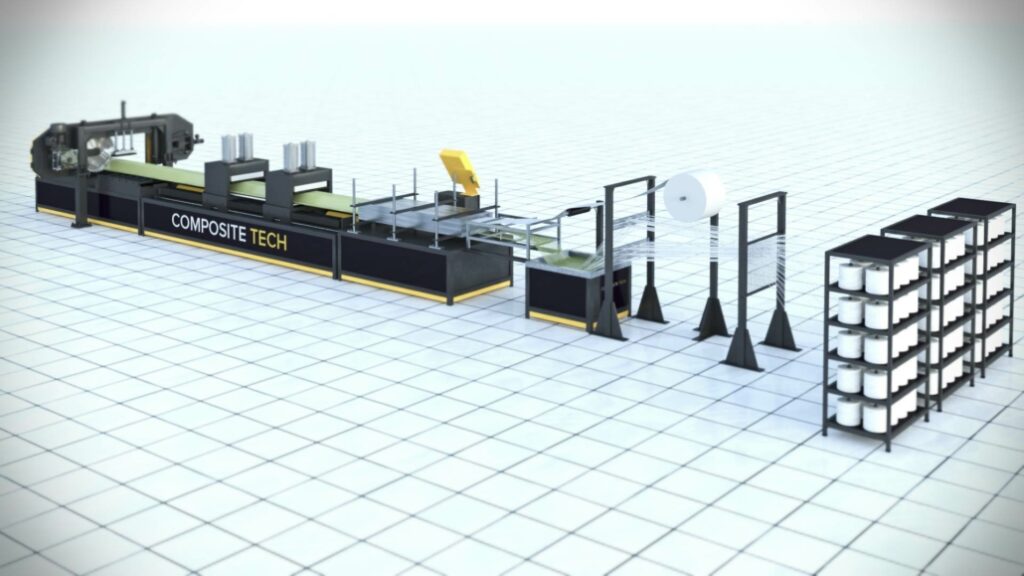

تُقدم شركة Composite-Tech أحدث خطوط إنتاج مقاطع FRP المبثوقة، والتي طورتها الشركة حديثًا، لرتقاء صناعة المواد المركبة إلى آفاق جديدة. تتميز مقاطع FRP المبثوقة بمزايا عديدة مقارنةً بمقاطع البلاستيك والألمنيوم التقليدية، مما يرتقي بالصناعة إلى مستوى جديد من الاستدامة والفعالية.

تقدم خطوط إنتاج مقاطع GFRP من Composite-Tech ما يلي:

- الأتمتة الكاملة

- مجموعة واسعة من أنواع الملفات الشخصية والأشكال والتطبيقات (انظر أدناه)

- تكنولوجيا الإنتاج الفعالة من حيث التكلفة

- عملية الإنتاج المستدامة

تُستخدم مقاطع الفيديو المركبة المصنوعة من البلاستيك المقوى بألياف الزجاج Composite-Tech في:

- البناء المدني

- بناء المستودعات

- بناء الواجهة البحرية

- تقوية هيكل المبنى

- الجسور والسلالم والمنصات

تم تصميم معداتنا لتكون موثوقة وعالية الإنتاجية وفريدة من نوعها في التكنولوجيا التي نستخدمها! جميع تطوراتنا وابتكاراتنا حاصلة على براءات اختراع، مما يضمن ليس فقط فعالية عالية لاستثمارك، بل وأيضًا سوقًا خالية من المنافسة. علاوة على ذلك، لضمان موثوقية جميع وحدات خط الإنتاج، نستخدم فقط المكونات التي اجتازت اختباراتنا الصارمة وتقييمات الأداء.

من خلال الحصول على معدات إنتاج ملفات تعريف GFRP من Composite-Tech، يتمتع عملاؤنا أيضًا بالنتائج التالية:

- المساعدة في اختيار الأماكن الخاصة

- يقوم المتخصصون لدينا بتثبيت المعدات وإجراء أعمال التشغيل

- تدريب الموظفين

- نصائح مستمرة من خبرائنا الفنيين

الخصائص التقنية

مزايا مقاطع FRP المبثوقة مقارنة بأمثلة المقاطع المستخدمة تقليديًا:

- مقاومة التآكل – يتميز ملف GFRP بمقاومته للتآكل الناتج عن مياه البحر والمواد الكيميائية والنفط والغاز والحرارة والأشعة فوق البنفسجية والظروف البيئية القاسية.

- الاستدامة – المنتج النهائي لخطوط إنتاج مقاطعنا المركبة يساعد على تحقيق الاستدامة في البناء، وتحويل الصناعة نحو حل أكثر صداقة للبيئة.

- القوة / خفيفة الوزن - قوة عالية تجعل مقاطع الألياف الزجاجية مقاومة للاهتزاز والقوى الداخلية والخارجية الأخرى. مقاطع FRP خفيفة الوزن مقارنةً بالحديد المطاوع، وخفيفة الوزن. فُولاَذمقاطع من الألومنيوم والبولي إيثيلين عالي الكثافة. خفة الوزن تضمن سهولة التعامل والنقل والتركيب. هذه الصفات تجعل مقاطع GFRP أكثر متانة وموثوقية واقتصادًا من المقاطع التقليدية.

- خيارات التخصيص - مناسب لجميع المتطلبات الصناعية الممكنة تقريبًا.

- عدم التلوث - مقاطع GFRP لا تصدأ وبالتالي ليس لها أي تأثير على البيئة.

- الحد الأدنى من الصيانة والإصلاح - العمر الطويل يزيل التكاليف الإضافية المرتبطة بالإصلاحات.

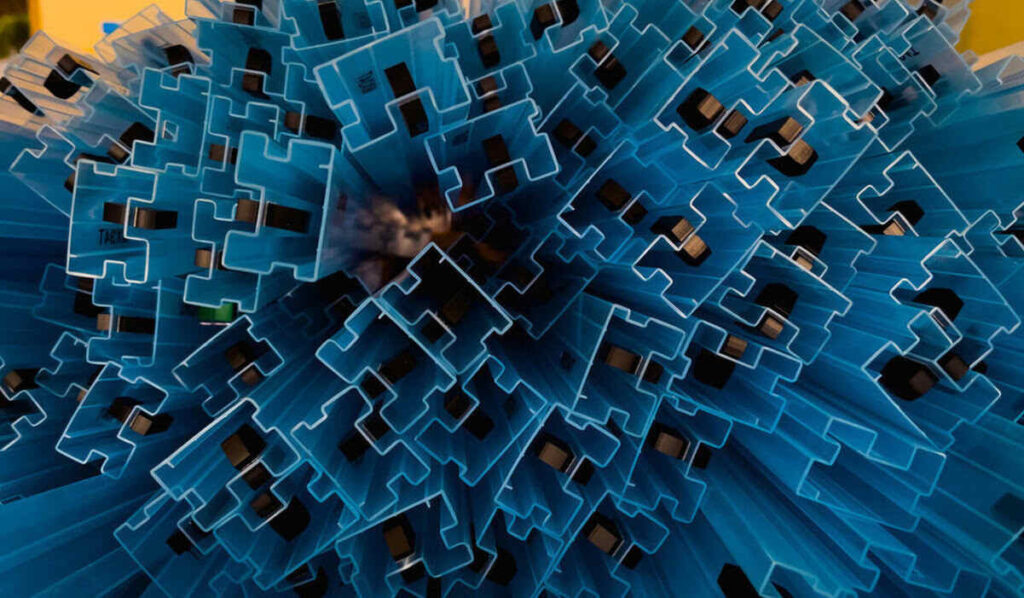

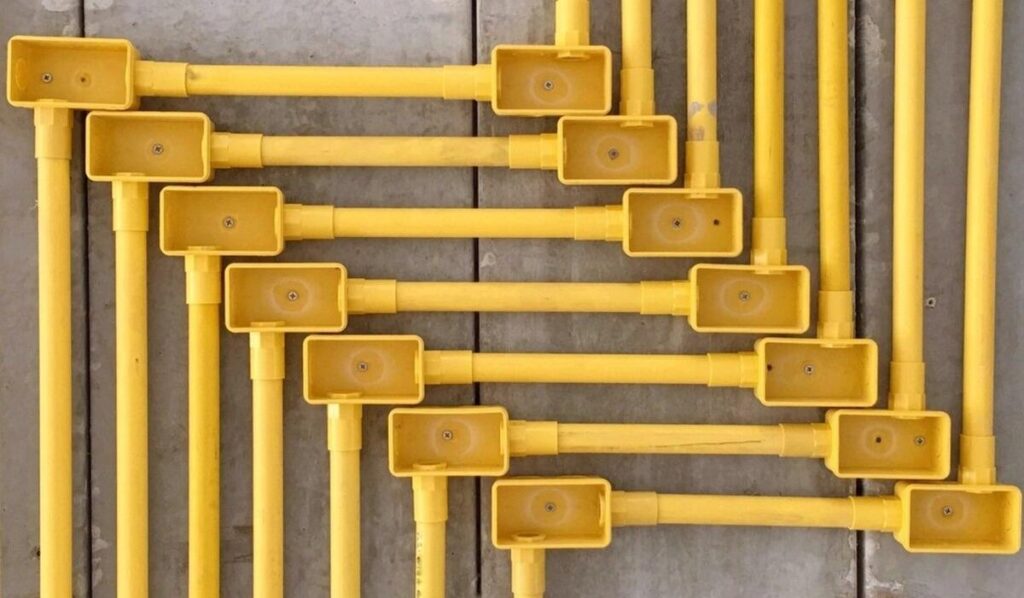

أشكال مقاطع FRP المركبة والمضغوطة:

- أنابيب

- العوارض

- قضبان (مربعة)

- أشرطة (مربعة)

- ملفات تعريف الزاوية

- ملفات تعريف U / C / Z / T

- ملفات تعريف الزاوية

- عظام الكلب

- الأشكال المخصصة

إنتاج حديد التسليح GFRP جاهز للاستخدام!

من خلال مطابقة سعر مبيعات حديد التسليح GFRP الخاص بك مع حديد التسليح الفولاذي، يمكنك تحقيق هامش ربح يزيد عن 120%!

احصل على خط الإنتاج الخاص بك في غضون شهرين فقط بعد تقديم الطلب واسترد استثمارك في غضون 3 أشهر فقط بعد إطلاق الإنتاج.