Современные строительные технологии переходят на использование композитных материалов, таких как арматура из стеклопластика (GFRP). Эти материалы не только обладают высокой производительностью, но и значительными экологическими преимуществами, способствуя устойчивому развитию. В данной статье рассматриваются конкретные данные, связанные с Преимущества стеклопластика по сравнению со сталью, уделяя особое внимание углеродному следу, потреблению энергии, сроку службы и общему воздействию на окружающую среду.

Содержание

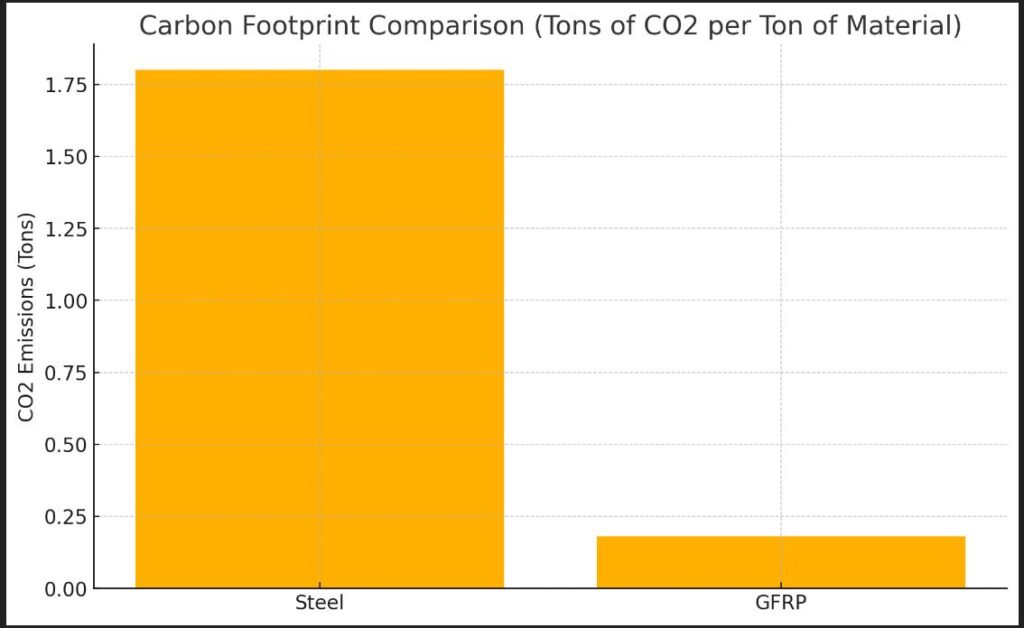

1. Сравнение углеродного следа: стеклопластик против стали

Производство стеклопластика приводит к значительно более низким выбросам CO₂ по сравнению со сталью. Это связано с отсутствием энергоемких процессов плавки и более низкими общими энергозатратами. В среднем при производстве одной тонны стали выделяется 1,8 тонны CO₂, тогда как производство того же количества GFRP генерирует только 0,18 тонн CO₂.

Рисунок 1: Сравнение углеродного следа стали и стеклопластика. Стеклопластик оказывает на 90% меньшее воздействие на окружающую среду, чем сталь.

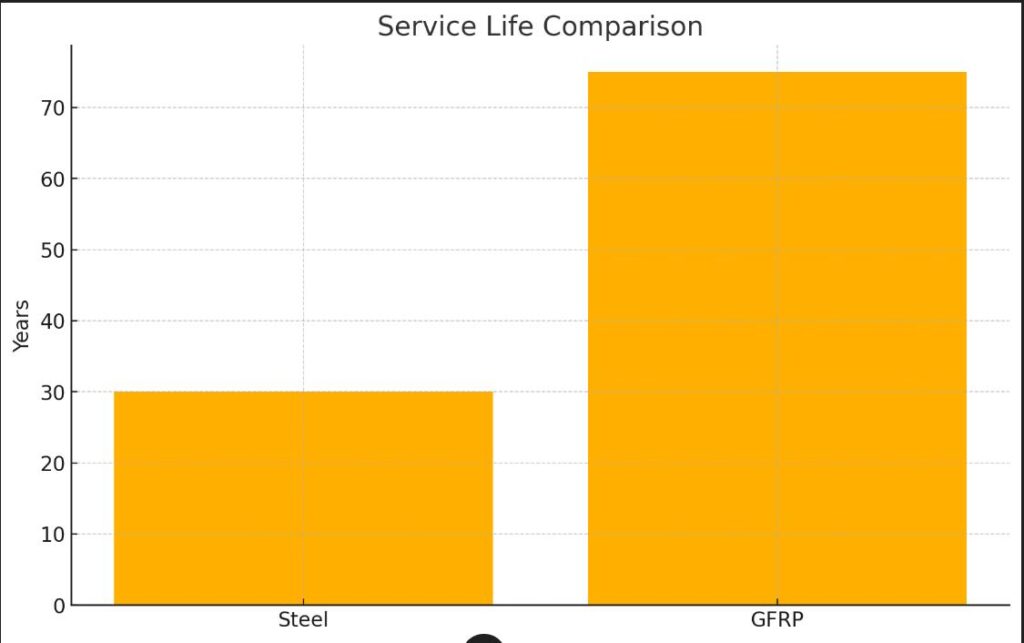

2. Долговечность и снижение затрат на обслуживание

Коррозионная стойкость GFRP делает его идеальным для конструкций, требующих длительного срока службы. В то время как стальные элементы требуют замены каждые 30 лет из-за коррозии и других повреждений стеклопластик может прослужить более 75 лет без ухудшения.

Рисунок 2: Сравнение срока службы материалов. Стеклопластик служит более чем в два раза дольше стали, что значительно снижает затраты на техническое обслуживание

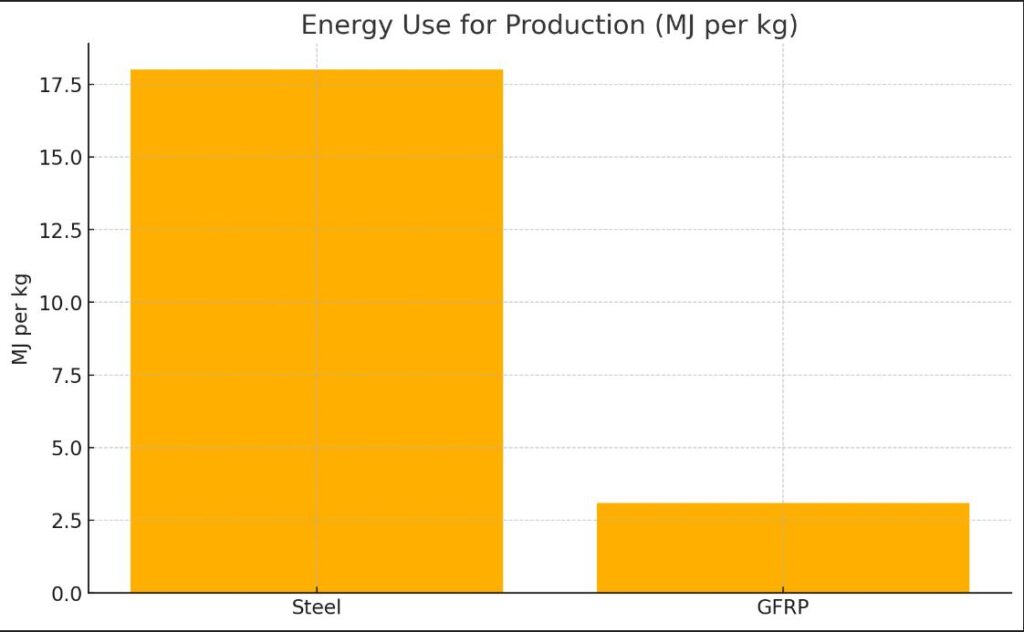

3. Потребление энергии и эффективность транспорта

Производство стеклопластика более энергоэффективно. При производстве одного килограмма стали потребляется 18 МДж, GFRP требует только 3,1 МДж на килограмм. Это различие делает композитные материалы более устойчивыми, снижая их вклад в глобальное потепление.

Рисунок 3: Потребление энергии на килограмм материала. Производство стеклопластика требует значительно меньше энергии по сравнению со сталью.

4. Переработка и утилизация отходов

В отличие от стальной арматуры, которую необходимо отделять от бетона во время переработки, GFRP можно перерабатывать вместе с отходами бетона. Это упрощает процесс переработки и сокращает количество строительных отходов. Арматура на основе базальта, тип FRP, обеспечивает полную перерабатываемость без потери своих свойств, что делает ее экологически чистой альтернативой.

5. Экономические выгоды

Хотя GFRP может показаться более дорогим на первый взгляд, его длительный срок службы и низкие затраты на обслуживание делают его экономически выгодным в долгосрочной перспективе. Композитные материалы особенно подходят для проектов, требующих минимального обслуживания и устойчивости к суровым условиям, таких как мосты, морские сооружения и промышленные объекты.

6. Вклад в устойчивое развитие

Использование композитных материалов способствует достижению целей устойчивого развития (ЦУР). GFRP снижает углеродный след строительных проектов, снижает потребление энергии и уменьшает объем строительных отходов. Компании, внедряющие эти материалы, демонстрируют свою приверженность экологическим стандартам, что становится ключевым конкурентным преимуществом на современном рынке.

Заключение

GFRP и другие композитные материалы становятся необходимыми в переходе строительной отрасли к устойчивому развитию. Они сокращают выбросы углерода, продлевают срок службы конструкций и снижают эксплуатационные и эксплуатационные расходы. Внедрение этих материалов помогает компаниям соответствовать мировым экологическим стандартам и укрепляет их позиции на рынке.

Узнать больше: