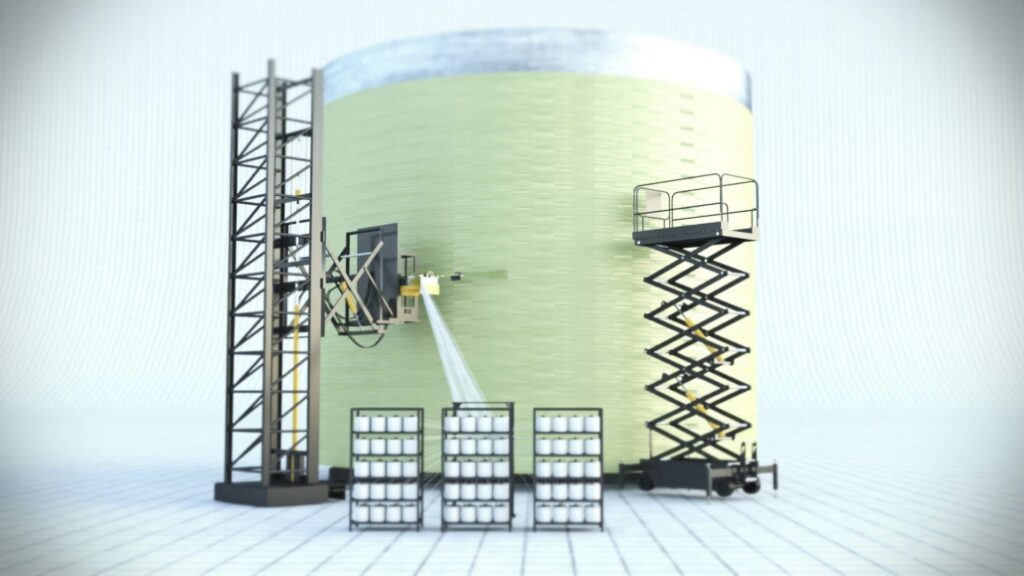

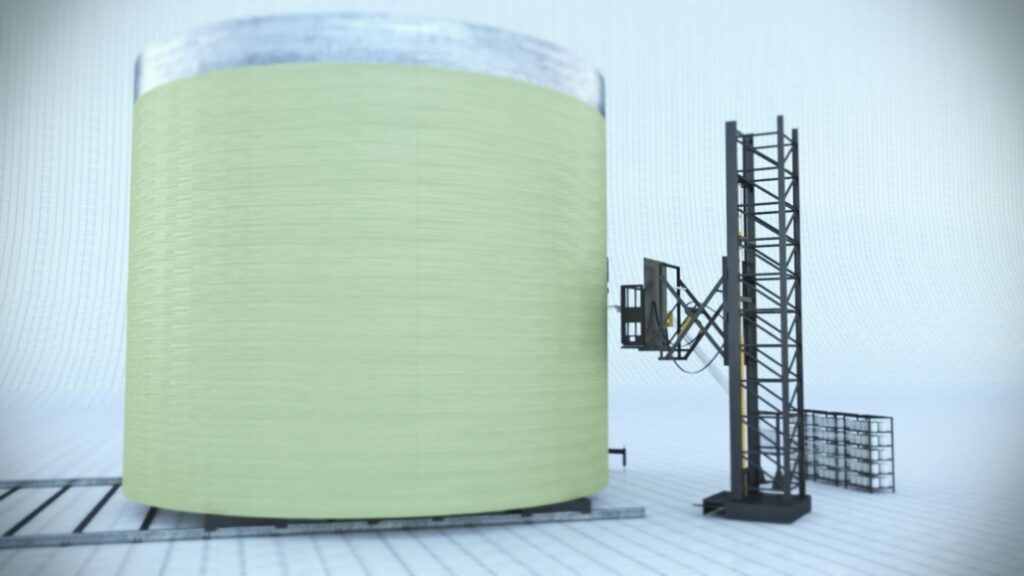

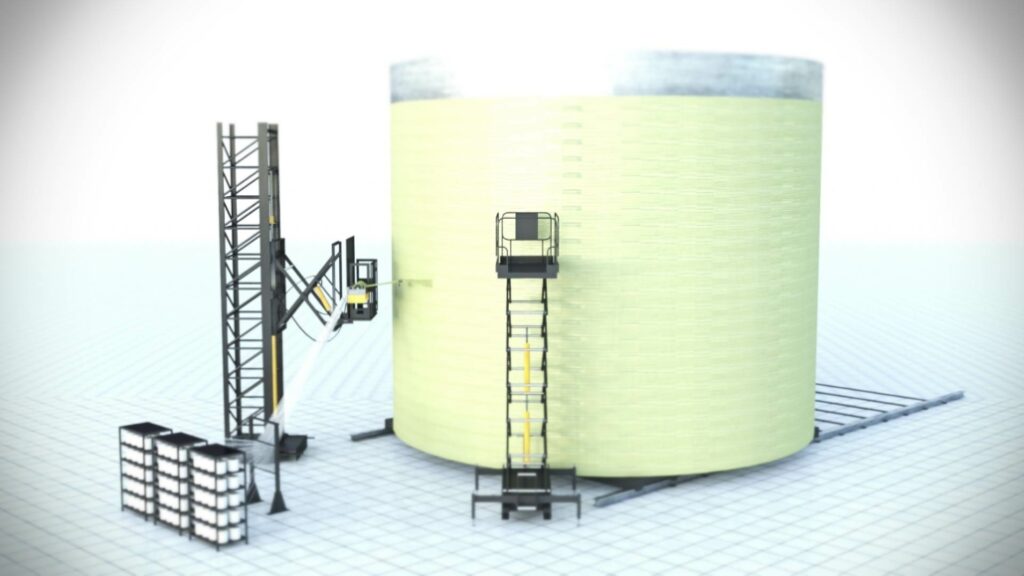

Composite-Tech lleva la industria de los composites a un nuevo nivel con la introducción de nuestra nueva línea de producción de silos de FRP. Los silos de composite, fabricados con fibra de vidrio, ofrecen numerosas ventajas sobre los silos metálicos convencionales de alta resistencia, elevando la industria a un nuevo nivel de sostenibilidad y eficacia.

Las líneas de producción de silos de FRP de Composite-Tech ofrecen:

- Automatización completa

- Amplia gama de tipos de silos y aplicaciones (ver más abajo)

- Tecnología de producción rentable

- Proceso de producción sostenible

Los silos compuestos de PRFV de Composite-Tech se utilizan en:

- Industria del petróleo y el gas

- Industria agrícola (almacenamiento de granos y más)

- Almacenamiento de agua

- Residuos y agua de mar

- Almacenamiento de productos químicos

- Bajo oxígeno / Alta presión

Posibles formas de silos de FRP posibles con nuestra línea de producción:

- Silo estándar

- Fondo plano

- Tolva (silo de fondo de embudo)

- Carga de camión/tren

- Dimensión variable

Nuestros equipos están diseñados para ser confiables, altamente productivos y con una tecnología única. Todos nuestros desarrollos e innovaciones están patentados, lo que garantiza no solo una alta rentabilidad de su inversión, sino también un mercado libre de competencia. Además, para garantizar la confiabilidad de todos los módulos de la línea de producción, utilizamos únicamente componentes que han superado rigurosas pruebas y evaluaciones de rendimiento.

Al adquirir equipos de producción de silos de PRFV de Composite-Tech, nuestros clientes también obtienen los siguientes resultados:

- Cálculos vinculados a la fabricación de un producto final específico

- Nuestros especialistas realizan la instalación de equipos y realizan trabajos de puesta en marcha.

- Capacitación del personal

- Asesoramiento continuo por parte de nuestros expertos técnicos

Características técnicas

Características técnicas de la línea de producción de silos de PRFV

| Objetivo: | producción de silos de fibra de vidrio |

| Voltaje: | 380 V / 50 Hz |

| Fuerza: | 30 kilovatios |

| Rendimiento de línea: | Depende del producto final |

| Longitud del equipo: | 12 metros |

| Ancho: | 2,5 metros |

| Altura: | 2,8 metros |

Ventajas de los silos de FRP en comparación con los silos utilizados convencionalmente:

- Resistencia a la corrosión – Los silos de PRFV son resistentes a la corrosión resultante del agua de mar, productos químicos, petróleo, gas, calor, rayos UV y condiciones ambientales extremas.

- Ahorro de espacio Para el almacenamiento de granos agrícolas, los almacenes son otra opción. Sin embargo, en este caso, los silos ahorran mucho más espacio al estar ubicados verticalmente.

- Cero desperdicio de producto almacenado – La colocación vertical de los silos facilita la descarga del producto almacenado y no se producen desperdicios de producto por falta de compartimentos internos, estantes, etc.

- Temperatura interna, humedad y presión Los silos de PRFV se construyen con un sistema de gestión interno en mente. Como resultado, no solo se cumplen todos los requisitos relacionados con el almacenamiento en la industria agrícola y del petróleo y gas, sino que también se simplifican, gracias a las mejores características primarias del comportamiento de los silos de PRFV.

- Sostenibilidad – El producto final de nuestras líneas de producción de silos compuestos contribuye a la sostenibilidad en la construcción, llevando a la industria hacia una solución más ecológica.

- Durabilidad / Ligereza Su alta resistencia hace que los silos de fibra de vidrio resistan la vibración y otras fuerzas internas y externas que se les aplican. Los silos de PRFV son ligeros en comparación con los de hierro dúctil, acero dulce y HDPE. Su bajo peso facilita su manejo, transporte e instalación. Estas cualidades hacen que los silos de PRFV sean mucho más duraderos, fiables y económicos que los silos convencionales.

- Resistencia a la inflamación – A diferencia de sus homólogos de hierro, los silos de PRFV no explotan y no se incendian ni mantienen su forma.

- Opciones de personalización – Adecuado para prácticamente cualquier requisito industrial posible.

- Falta de contaminación – Los silos de FRP no se oxidan y, por lo tanto, no afectan en ningún modo a los líquidos almacenados, independientemente de que se trate de agua, gas líquido o productos químicos.

- Mantenimiento y reparación mínimos – La larga vida útil elimina los costos adicionales vinculados a las reparaciones.

- Resistencia a la presión – La alta rigidez y la alta capacidad de carga de compresión de los silos de FRP evitan fluctuaciones de presión de estallido.

- Eficiencia hidráulica– Los silos de PRFV tienen una superficie interna lisa que favorece excelentes características hidráulicas, alta capacidad de flujo y baja fricción.

¡Producción de varillas de refuerzo de PRFV llave en mano en España!

Al combinar el precio de venta de sus varillas de refuerzo de PRFV con el de sus varillas de refuerzo de acero, obtendrá un margen de beneficio de más de 120%.

Obtenga su línea de producción en solo 2 meses después de realizar un pedido y recupere su inversión en solo 3 meses después del lanzamiento de la producción.

Aplicación de silo de FRP

Los silos de FRP se utilizan comúnmente en aplicaciones sobre el suelo donde la alta resistencia, la eficiencia hidráulica y la alta resistencia son esenciales.