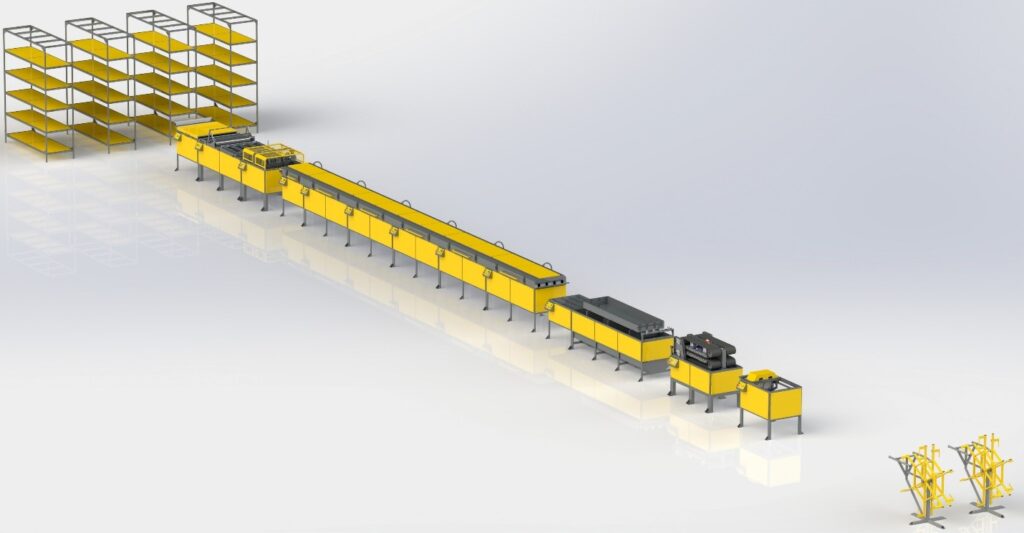

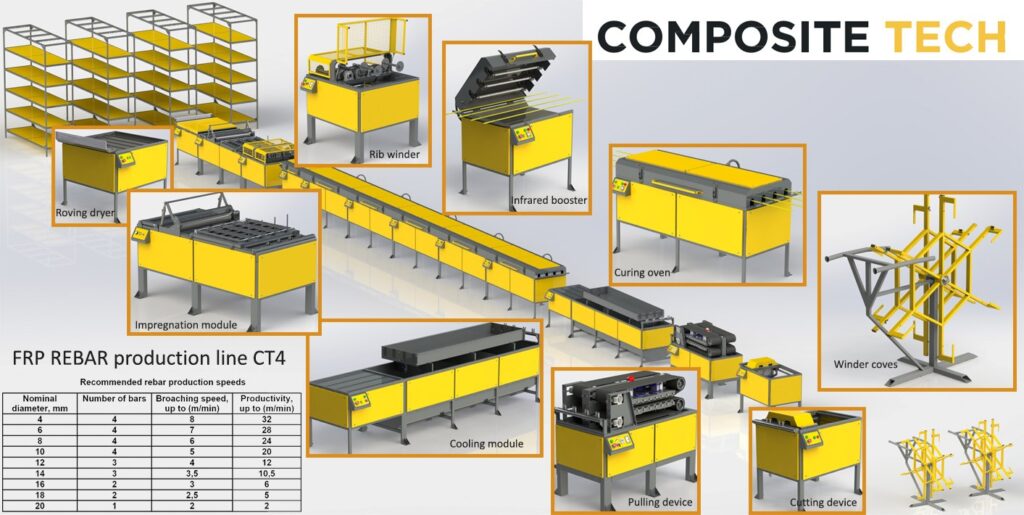

La máquina CT4 está diseñada para la producción de varillas de refuerzo de polímero reforzado con fibra de vidrio (PRFV) con diámetros de entre 4 mm y 20 mm. Puede producir simultáneamente hasta 4 varillas de refuerzo, lo que garantiza una alta productividad y rentabilidad. La máquina consta de varios componentes clave, cada uno de los cuales desempeña una función específica en el proceso de producción.

Características principales de CT4

| Característica | Valor |

|---|---|

| Diámetros de varillas de refuerzo | 4 mm - 20 mm |

| Número de varillas | Hasta 4 |

| Productividad general | Hasta 32 m/min |

| Componentes | 12 módulos principales |

1. Filete

- Función: Sujeta carretes de mecha y crea tensión inicial en los hilos utilizando anillos guía por donde pasan los hilos.

2. Secador de mechas

- Función: Alinea y seca los hilos de mecha, asegurando una distribución uniforme del calor y un contenido de humedad óptimo para la posterior impregnación con resina polimérica.

3. Módulo de impregnación

- Función: Impregna los hilos de mecha con resina y los prensa para mantener las propiedades cruciales del aglutinante de polímero (flujo, velocidad de curado, temperatura) mientras reduce el consumo de polímero a través de un moderno sistema de prensado.

4. Enrollador de costillas

- Función: Enrolla perfiles periódicos (costillas) con pasos de bobinado precisos para cada tamaño de varilla de refuerzo, asegurando una forma de varilla estrictamente cilíndrica y eliminando el aire de la varilla impregnada.

5. Amplificador de infrarrojos

- Función: Acelera el proceso de polimerización de la resina.

6. Horno de túnel

- Función: Se utiliza para la polimerización de resina, donde la resina se cura y se forma la barra de refuerzo de PRFV final.

7. Módulo de enfriamiento

- Función: Enfría la varilla de refuerzo de PRFV.

8. Dispositivo de tracción

- Función: Tira de la varilla de refuerzo de PRFV y determina la velocidad de tracción.

9. Dispositivo de corte

- Función: Corta la varilla de refuerzo de PRFV a la longitud deseada.

10. Winder Coves

- Función: Coloca las barras de refuerzo de PRFV en bobinas.

11. Bobinadora automática (opcional)

12. Dispositivo para torcer hilos de fibra de vidrio

- Función: Forma hilos acanalados retorciendo hilos de mecha.

Productividad

| Diámetro de la varilla de refuerzo (mm) | Número de varillas | Velocidad de tracción (m/min) | Productividad (m/min) |

|---|---|---|---|

| 4 | 4 | 8 | 32 |

| 6 | 4 | 7 | 28 |

| 8 | 4 | 6 | 24 |

| 10 | 4 | 5 | 20 |

| 12 | 3 | 4 | 12 |

| 14 | 3 | 3.5 | 10.5 |

| 16 | 2 | 3 | 6 |

| 18 | 2 | 2.5 | 5 |

| 20 | 1 | 2 | 2 |

Estos datos son aproximados y dependen de las características de las resinas utilizadas y de las condiciones ambientales.

Especificaciones técnicas del CT4

| Parámetro | Valor |

|---|---|

| Fuente de alimentación | 380 V, 50 Hz |

| Consumo de energía | 50 kW |

| Dimensiones | 12000 x 2500 x 2500 mm |

| Peso | 5000 kilos |

| Temperatura de funcionamiento | 15-30°C |

Las varillas de refuerzo de PRFV representan un avance significativo en los materiales de construcción, ya que combinan alta resistencia, flexibilidad y resistencia a los factores ambientales. Su uso en diversos proyectos de construcción en España no solo mejora la integridad estructural, sino que también crea nuevas oportunidades para diseños innovadores y prácticas de construcción más eficientes.

Ventajas de la máquina CT4

- Alta productividad y eficiencia gracias a la producción simultánea de hasta 4 varillas de refuerzo.

- Reducción del consumo de polímeros Gracias al innovador sistema de prensado.

- Precisión y calidad del producto garantizado mediante el uso de componentes y sistemas de control de alta tecnología.

- Fiabilidad y durabilidad de todos los componentes de la máquina, garantizando una larga vida útil y unos costes de mantenimiento mínimos.

La máquina CT4 es una solución ideal para empresas dedicadas a la producción de varillas de refuerzo de PRFV, proporcionando alta productividad, rentabilidad y calidad constante del producto.

¡No pierda la oportunidad de hacer su negocio más rentable con las tecnologías avanzadas de Composite-Tech! Contáctanos Para obtener más información y realizar un pedido.