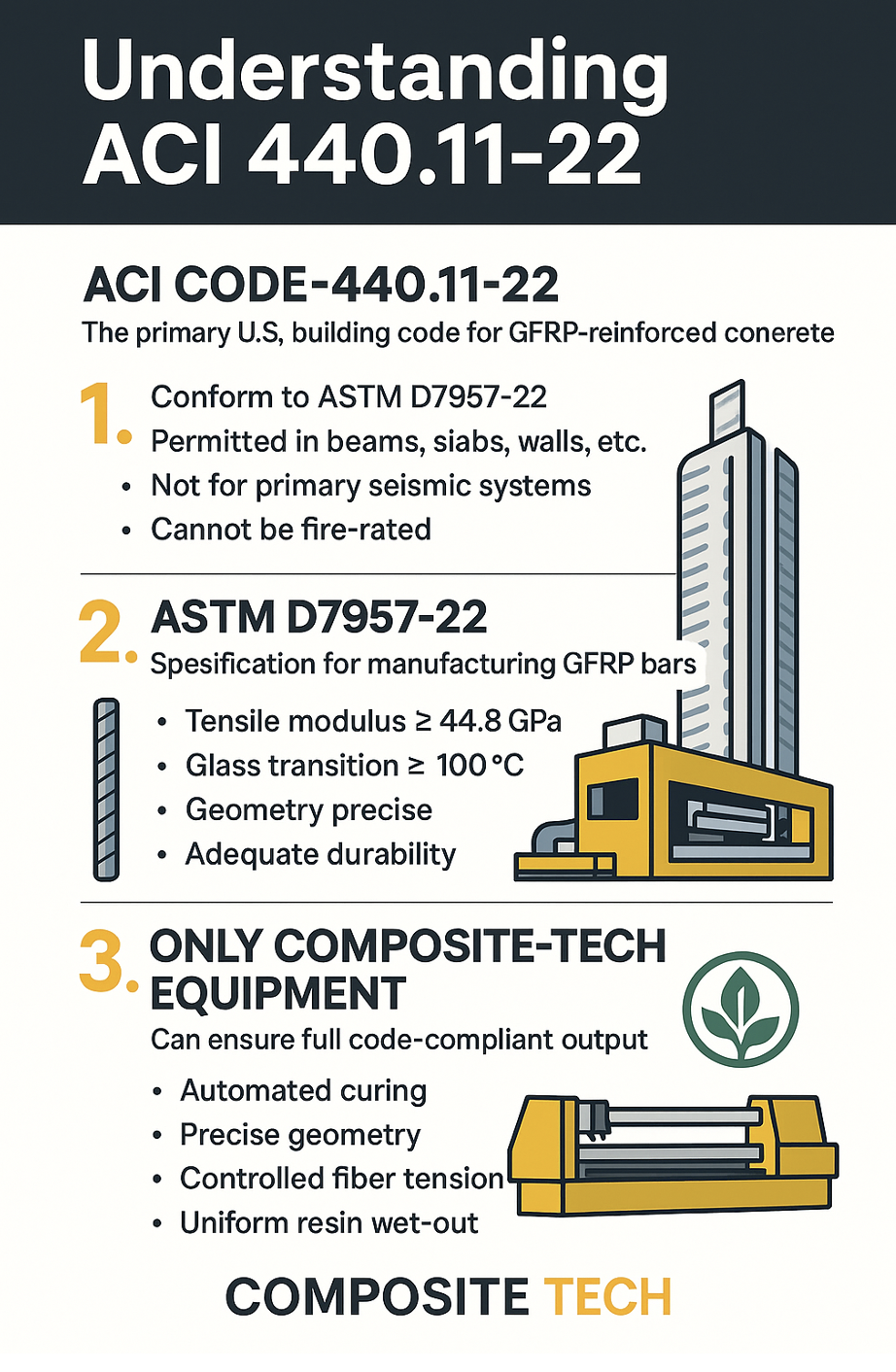

La introducción de CÓDIGO ACI-440.11-22 marca un punto de inflexión en la industria estadounidense de FRP. Por primera vez, EE. UU. cuenta con un código de construcción formal y vinculante que regula el uso de GFRP (polímero reforzado con fibra de vidrio) barras en hormigón estructural.

Para los fabricantes, este código no es opcional.

Si sus barras de GFRP no cumplen con ACI 440.11-22 y ASTM D7957-22, no se pueden utilizar en la mayoría de los proyectos comerciales y de infraestructura de EE. UU.

Este artículo desglosa los requisitos del código, cómo afecta a los fabricantes y por qué la calidad del equipo determina si su producto superará el escrutinio de ingeniería estadounidense.

¿Qué diferencia a ACI 440.11-22 de las directrices anteriores sobre FRP?

Antes de 2022, los diseñadores usaban ACI 440.1R-15, una recomendación, no un requisito legal.

ACI 440.11-22 es un código de construcción completo, desarrollado a través del mismo proceso acreditado por ANSI que ACI 318.

Esto significa:

- Es exigible.

- Los departamentos de construcción lo utilizan como referencia.

- Está reconocido por los Departamentos de Transporte estatales.

- Dicta cómo debe utilizarse el FRP en la práctica. Construcción en Estados Unidos.

El código incluye 27 capítulos Cubriendo materiales, resistencia de diseño, funcionalidad, vigas, losas, columnas, muros, cimientos, juntas y evaluación de estructuras existentes.

El par obligatorio: ACI 440.11-22 y ASTM D7957-22

ACI 440.11-22 establece explícitamente:

“Todas las barras de GFRP utilizadas bajo este código deben cumplir con la norma ASTM D7957.”

ASTM D7957-22 establece la requisitos mínimos de fabricación, incluido:

Propiedades mecánicas

- Módulo de tracción ≥ 44,8 GPa (6,5 Msi)

- Resistencia a la tracción y deformación de rotura por tamaño

- Resistencia al corte ≥ 131 MPa

Requisitos de durabilidad

- resistencia a los álcalis

- absorción de agua

- Tg ≥ 100 °C (212 °F)

- Grado de curación ≥ 95%

Requisitos geométricos

- Tolerancias de diámetro

- límites de ovalidad

- Deformación superficial o recubrimiento de arena

- Marcado de barra obligatorio

Si no puede generar informes ASTM D7957-22, sus barras no se pueden utilizar en proyectos ACI 440.11-22. Punto.

Usos permitidos y prohibidos según ACI 440.11-22

Dónde está aprobado el GFRP

- Vigas

- Losas

- Paredes

- Columnas

- Cimientos

- elementos prefabricados

- Evaluaciones de la estructura existente

Restricciones sísmicas

- SDC A: totalmente permitido

- SDC B–C: permitido únicamente en elementos que no sean SFRS

- SDC D–FNo permitido en sistemas sísmicos primarios

Motivo: falta de ductilidad y comportamiento de rótula plástica.

Limitaciones de fuego

Debido a que las matrices poliméricas se ablandan cerca de Tg ≈ 100°C:

- PRFV no puedo Puede utilizarse en elementos resistentes al fuego sin necesidad de pruebas personalizadas.

Esto debe comunicarse claramente a ingenieros y clientes.

Cómo la norma ACI 440.11-22 modifica la filosofía de diseño de FRP

A diferencia del acero, el PRFV es:

Lineal-elástica hasta la rotura frágil, sin meseta de fluencia.

Esto afecta a:

- factores de reducción de fuerza

- Estados límite rectores

- Comprobaciones de funcionalidad (deflexión + ancho de grieta)

En muchos casos, El diseño está controlado por la rigidez, no por la resistencia..

Fabricantes con módulo de tracción más alto Ayuda directamente a los ingenieros a reducir la cantidad y el espaciado de las barras. Esto supone una importante ventaja competitiva.

Qué deben hacer los fabricantes de FRP para cumplir con ACI 440.11-22

Calificación completa ASTM D7957-22

Pruebas requeridas:

- Ensayos de tracción (ASTM D7205)

- Pruebas de módulo

- Resistencia al corte (ASTM D7617)

- Bond (ASTM D7913)

- Absorción de agua (ASTM D570)

- Tg/grado de curación

- acondicionamiento alcalino

Todos los informes de pruebas verificados deben estar fácilmente disponibles para los ingenieros estadounidenses.

Proporcionar datos técnicos transparentes

Los ingenieros de proyectos estadounidenses esperan:

- Valores garantizados (f_fu, E_f, deformación de rotura)

- Curvas de tensión-deformación

- Datos de durabilidad

- Documentación de control de calidad por lotes

- factores de reducción ambiental recomendados

La confianza se construye a través de la documentación, no de las promesas de marketing.

Publica tu módulo real

En los diseños regidos por la rigidez, el módulo es el parámetro más importante.

Si sus barras de GFRP tienen:

- Módulo ≥ 50 GPa

- Resistencia ≥ 1000 MPa

Te vuelves mucho más atractivo para los especificadores estadounidenses.

Por qué la calidad del equipo determina el cumplimiento del código

Aquí comienza la parte más importante de la promoción de la marca Composite-Tech, y se basa en hechos, no en marketing.

Solo los equipos de alta precisión pueden producir barras que cumplan con los requisitos ACI + ASTM.

La geometría, la alineación de las fibras, la impregnación de la resina, el ciclo de curado y el perfil de la superficie requeridos por ASTM D7957-22 simplemente no se puede lograr con equipos manuales o de baja precisión..

Incluso pequeñas desviaciones en:

- diámetro,

- altura de las costillas,

- contenido de resina,

- grado de curación,

- Tg,

- fracción de volumen de fibra

conducir a fallos en las pruebas que descalifican las barras de refuerzo de los proyectos aprobados por ACI.

¿Por qué solo los equipos Composite-Tech pueden garantizar una producción que cumpla con las normas ACI?

Basándonos en la filosofía de diseño e ingeniería de pruebas de las líneas Composite-Tech:

1. Los hornos de curado automatizados mantienen perfiles térmicos precisos.

→ garantizando Tg ≥ 100°C y polimerización completa.

2. Los sistemas de tensado de fibra controlado garantizan un V_f preciso.

→ que proporciona el módulo y la resistencia a la tracción requeridos por ASTM D7957.

3. Los baños de resina diseñados con precisión garantizan una impregnación uniforme.

→ eliminar huecos y microdefectos que reducen la resistencia al corte.

4. Los troqueles de conformado calibrados por CNC garantizan la geometría de la barra.

→ garantizar el cumplimiento de las tolerancias de diámetro y ovalidad.

5. Textura superficial uniforme (revestimiento de arena o estrías)

→ produciendo una resistencia de unión confiable según ASTM D7913.

6. Repetibilidad de la producción

→ esencial para el cumplimiento continuo en todos los lotes.

Como resultado:

Solo el sistema automatizado de Composite-Tech líneas de fabricación de GFRP pueden garantizar que las barras de refuerzo producidas en ellos cumplirán plenamente con—

y en muchos casos superan los requisitos mecánicos, geométricos y de durabilidad de ACI 440.11-22 y ASTM D7957-22.

Esto no es un eslogan.

Es un hecho de ingeniería respaldado por la precisión del diseño del equipo.

ACI 440.11-22 es ahora el código estadounidense autorizado para el hormigón reforzado con GFRP.

Cambia fundamentalmente lo que los ingenieros estadounidenses esperan de los fabricantes.

En una frase:

ACI 440.11-22 tells ingenieros cómo diseñar con GFRP.

Fabricantes de ASTM D7957-22 tells, ¿cuáles son sus varillas de refuerzo de PRFV Tiene que ser así.

Composite-Tech proporciona el equipo que hace posible ese nivel de calidad.

Para cualquier empresa de FRP que planee entrar o expandirse en el mercado estadounidense, alinearse con este código no es opcional; es el único camino viable.

Más información:

- Varillas de refuerzo compuestas en EE. UU.

- Malla de GFRP en EE. UU.

- Equipos de producción de PRFV en EE. UU.

- Por qué Composite-Tech es el líder mundial en equipos de producción de PRFV

- Por qué las empresas líderes a nivel mundial utilizan equipos profesionales de PRFV fabricados por Composite-Tech

- Varillas de refuerzo de PRFV vs. acero: costo, resistencia y beneficios a largo plazo en la construcción moderna

- Barras de refuerzo de PRFV frente a barras de refuerzo de acero: una comparación técnica completa

- Varillas de refuerzo de PRFV vs. acero: costo, resistencia y beneficios a largo plazo en la construcción moderna

- Documentación técnica