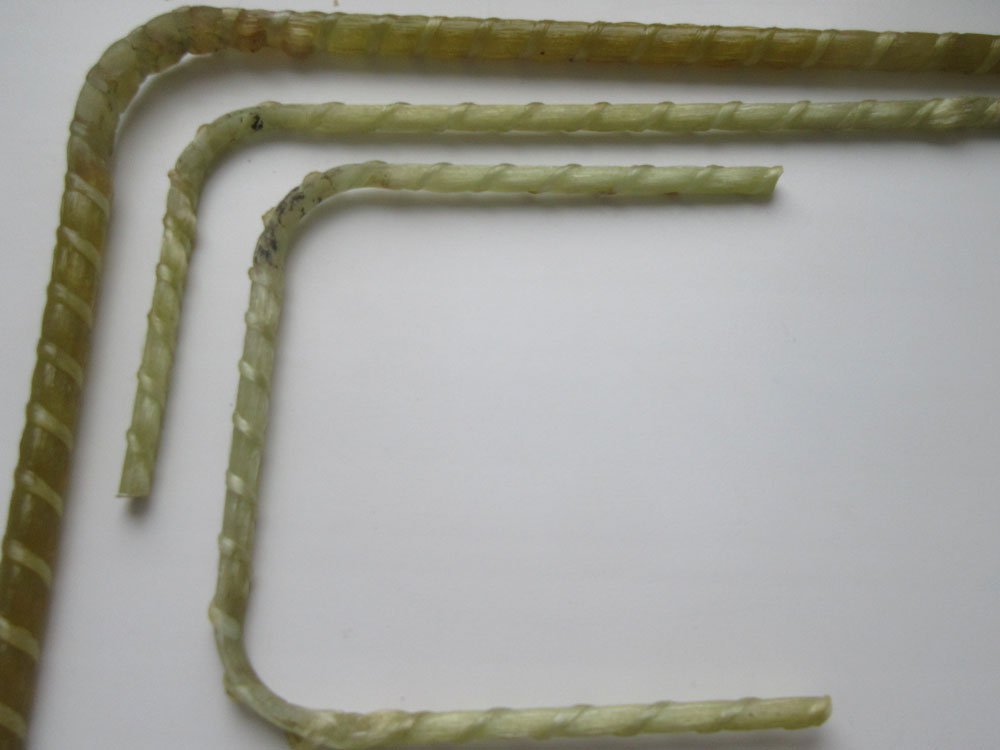

Composite-Tech se enorgullece de ser la única empresa a nivel mundial que fabrica máquinas CNC capaces de producir Elementos doblados de PRFV De cualquier forma, incluyendo elementos de ángulo inverso. Nuestro equipo avanzado puede crear elementos de PRFV doblados a medida, diseñados para barreras viales, puentes y numerosos otros proyectos de infraestructura. Estos elementos de PRFV son el futuro de la construcción, ofreciendo una durabilidad, ligereza y resistencia a la corrosión inigualables, lo que los convierte en una alternativa superior a las varillas de acero tradicionales.

Conclusiones clave

- Composite-Tech es el líder mundial en PRFV Soluciones de elementos doblados

- Principales beneficios del doblado de PRFV para proyectos de infraestructura: respetuoso con el medio ambiente, instalación más rápida, rentabilidad a largo plazo.

- Aplicaciones de los elementos doblados de PRFV:Estructuras de puentes, barreras viales, ideal para fachadas creativas y diseños estructurales únicos.

- Elegir PRFV para sus proyectos de construcción Garantiza sostenibilidad, resistencia y flexibilidad a largo plazo.

¿Por qué elegir elementos PRFV curvados para la construcción?

El uso de elementos de PRFV (polímero reforzado con fibra de vidrio) doblados abre nuevas posibilidades para la ingeniería estructural. A continuación, se explica por qué los elementos de PRFV están reemplazando las barras de acero tradicionales en una amplia gama de aplicaciones de construcción:

- Resistencia a la corrosiónA diferencia del acero, los elementos doblados de PRFV son inmunes a la corrosión. Esto los hace ideales para entornos hostiles, como infraestructuras costeras, construcción de puentes y zonas con alta humedad o exposición a sustancias químicas.

- LigeroLos elementos de PRFV son significativamente más ligeros que el acero, hasta 4 o 5 veces más ligeros. Esta reducción de peso disminuye la carga total sobre las estructuras y simplifica el transporte y la instalación.

- Resistencia química:Las varillas de refuerzo de FRP (Polímero Reforzado con Fibra) son resistentes a los agentes químicos, ofreciendo un rendimiento excepcional en entornos propensos a la exposición química, como zonas industriales.

- Alta durabilidad:Los elementos doblados de FRP tienen una vida útil superior a 50 años, manteniendo su integridad estructural sin requerir mantenimiento regular, a diferencia de las varillas de acero.

- No conductor y no magnéticoLas mallas y barras de refuerzo de FRP son electromagnéticamente neutras y no conductoras, lo que las hace perfectas para proyectos que requieren una interferencia electromagnética mínima, como subestaciones eléctricas y otras instalaciones sensibles.

Máquinas CNC de vanguardia para elementos doblados de PRFV de Composite-Tech

En Composite-Tech, nos especializamos en la producción de máquinas CNC que pueden fabricar elementos doblados de PRFV a medida de cualquier forma y tamaño, incluso aquellos con ángulos invertidos, algo que antes se consideraba imposible. Nuestra tecnología brinda a ingenieros y arquitectos la libertad de diseñar formas complejas de PRFV doblado con la máxima precisión, allanando el camino para soluciones arquitectónicas innovadoras.

Obtenga más información sobre Línea de producción profesional de elementos doblados de PRFV

Aplicaciones clave de los elementos doblados de PRFV

- Barreras vialesLas barras de refuerzo dobladas de PRFV son perfectas para fabricar barreras divisorias de carreteras que ofrecen durabilidad, flexibilidad y resistencia a la corrosión superiores, lo que garantiza la seguridad y estabilidad a largo plazo en las carreteras.

- Estructuras de puentesEn puentes, especialmente en zonas costeras donde la corrosión por agua salada es un problema, las varillas y mallas de FRP son la opción ideal. Son ligeras y resistentes a la corrosión, lo que prolonga su vida útil y reduce los costos de mantenimiento.

- Diseños arquitectónicosLa versatilidad de los elementos de PRFV curvados los hace ideales para fachadas creativas y diseños estructurales únicos. Los arquitectos pueden confiar en la flexibilidad de Malla de FRP para crear diseños estéticamente complejos manteniendo la resistencia y la durabilidad.

PRFV vs. Acero: Tabla comparativa

| Característica | GFRP (polímero reforzado con fibra de vidrio) | Acero |

| Resistencia a la corrosión | 100% resistente a la corrosión | Propenso a la corrosión |

| Peso | 4-5 veces más ligero que el acero | Pesado |

| Resistencia química | Resistente a los productos químicos | Baja resistencia química |

| Conductividad eléctrica | No conductor, ideal para zonas sensibles. | Conductivo |

| Durabilidad | Más de 50 años sin mantenimiento | Requiere mantenimiento regular |

| Costo de propiedad | Costos de mantenimiento más bajos | Más alto debido a reparaciones en curso |

| Fortaleza | Alta resistencia a la tracción | Alta resistencia a la tracción |

Beneficios de los elementos curvados de PRFV para proyectos de infraestructura

- Eficiencia de costos a largo plazoDebido a la durabilidad y los requisitos mínimos de mantenimiento de las barras de refuerzo de PRFV, el costo total de propiedad durante la vida útil de un proyecto es significativamente menor que el de las alternativas de acero.

- Instalación más rápida:La naturaleza liviana de la malla y las barras de refuerzo de PRFV permite una instalación más rápida y sencilla, lo que reduce los costos de mano de obra y los plazos del proyecto.

- Respetuoso con el medio ambiente:El uso de elementos curvados de PRFV reduce la huella de carbono asociada a la construcción, gracias a su longevidad, lo que elimina la necesidad de reemplazos y reparaciones frecuentes.

¿Por qué Composite-Tech es el líder mundial en soluciones de elementos doblados de PRFV?

Como pionero en tecnologías GFRP, Composite-Tech Liderando el mercado con máquinas CNC de última generación, diseñadas específicamente para la producción de varillas de refuerzo de PRFV dobladas, mallas y elementos de PRFV personalizados, nuestros equipos son muy solicitados en todo el mundo gracias a su precisión, eficiencia y capacidad para crear formas complejas que antes eran imposibles de lograr con otros materiales.

Ya sea que necesite elementos doblados para divisores de carreteras, puentes o diseños arquitectónicos, Composite-Tech ofrece soluciones incomparables en calidad e innovación.

Optimice sus proyectos con las soluciones GFRP de Composite-Tech

Elegir PRFV para sus proyectos de construcción garantiza sostenibilidad, resistencia y flexibilidad a largo plazo. Nuestras máquinas CNC garantizan que sus diseños se hagan realidad de la manera más eficiente, rentable y duradera posible. Contacte con Composite-Tech Visítenos hoy para conocer cómo nuestros elementos doblados de FRP pueden revolucionar su próximo proyecto de infraestructura.